High-voltage capacitor discharging device, method thereof and vehicle

A high-voltage capacitor and charge discharge technology, which is applied in the field of high-voltage capacitors, can solve the problems of long discharge time, increased cost, and non-compliance with safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

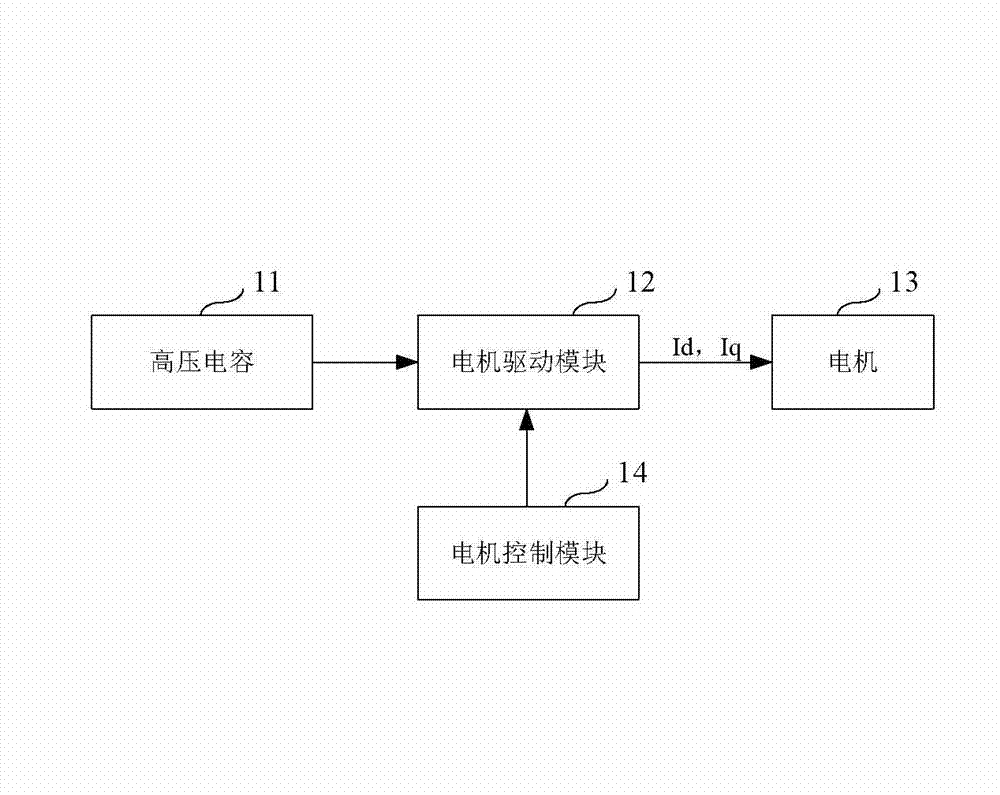

[0019] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

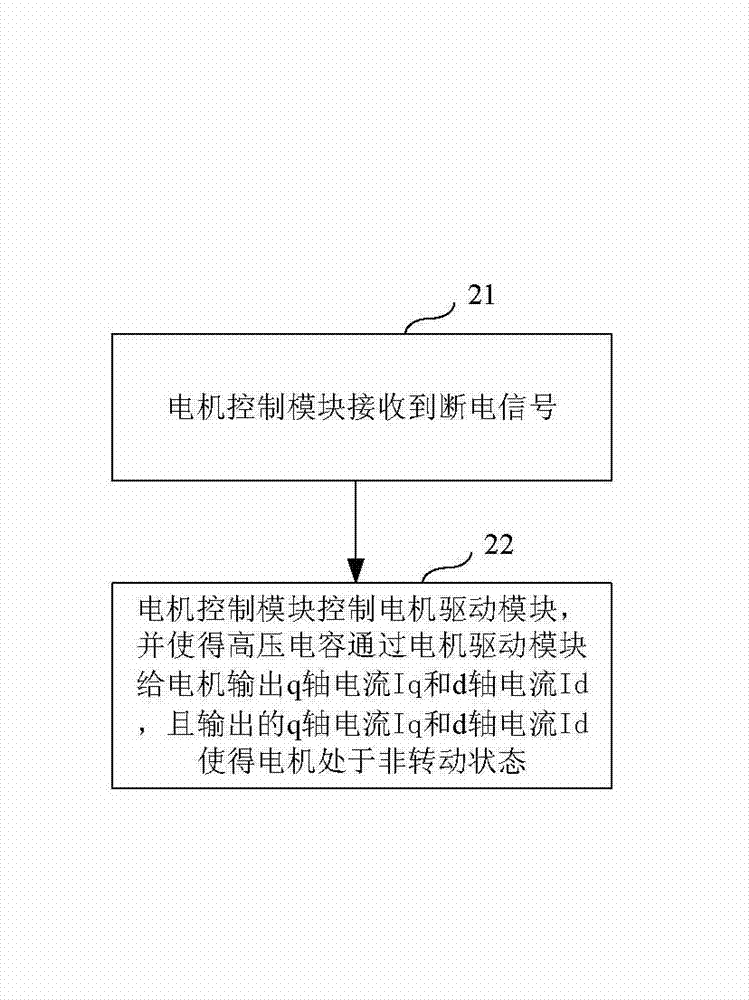

[0020] It is known from the prior art that the motor has a q-axis and a d-axis, wherein, when the current applied on the q-axis reaches a certain value (the certain value is different for different motors, which can be obtained through experiments and calculations), the motor It will produce rotation, and applying any large current on the d-axis will not cause the motor to rotate, but it will still consume energy.

[0021] The applicant of the present invention is based on the above theoretical knowledge, and through his own creative work, he finally thought of a solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com