Electrolytically-controlled micro-component picking and placing device and method

A pick-and-place device and micro-component technology, applied in the direction of electrolytic components, electrolytic process, manufacturing tools, etc., to achieve the effect of real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

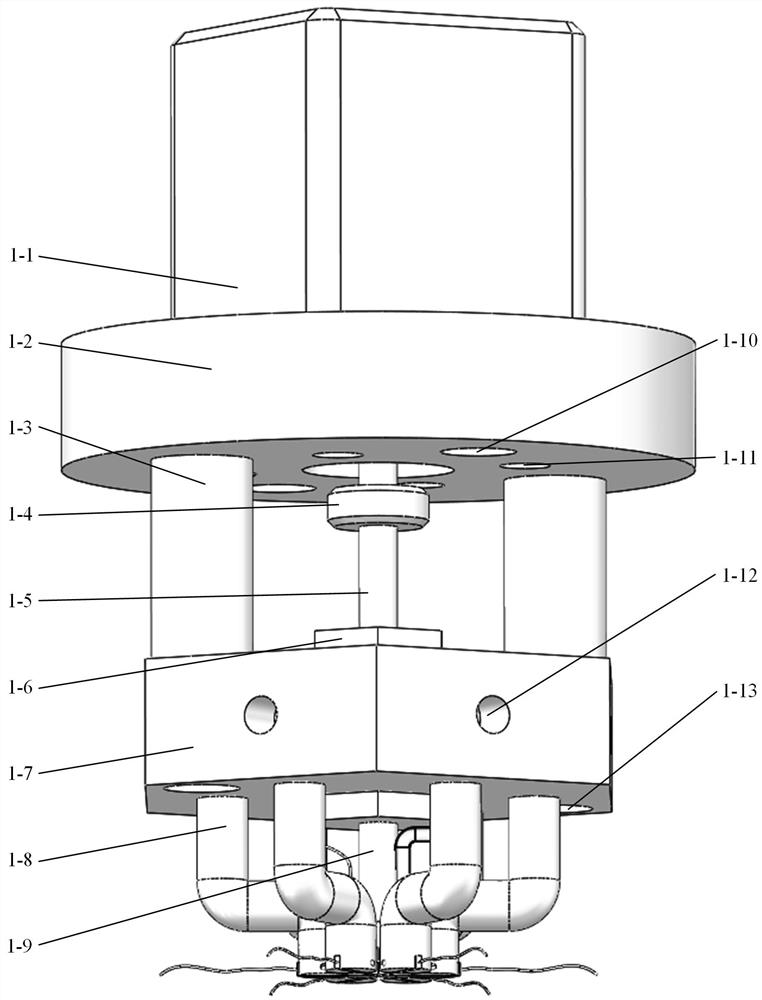

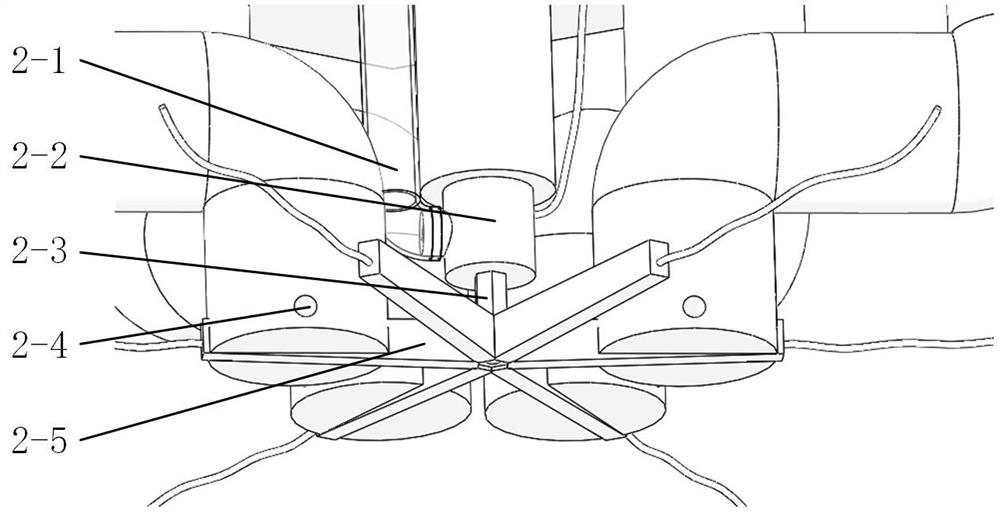

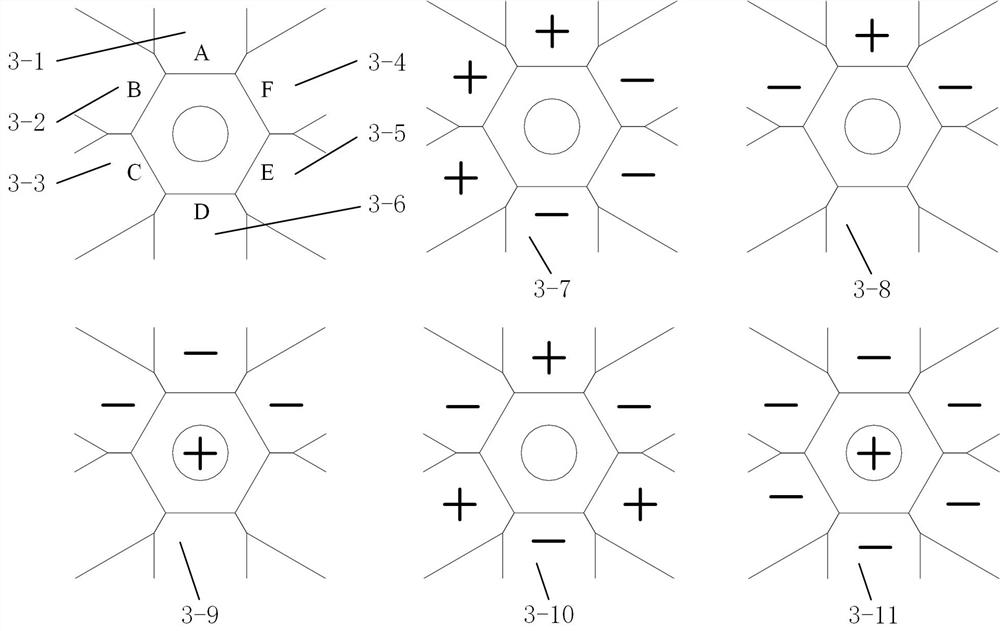

[0016] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Explain that the micro-component pick-and-place device described in this embodiment includes a micro-drive motor 1-1, a mounting frame 1-2, two sleeves 1-3, a shaft coupling 1-4, a ball screw 1-5, a connecting Nut 1-6, hexagonal mounting frame 1-7, six fixed frames 1-8, long connecting rod 1-9, hose 2-1, electrode connector 2-2, movable electrode 2-3, six The inert electrode 2-5, the mounting frame 1-2 and the micro drive motor 1-1 are connected by bolts through four through holes 1-11, and the micro drive motor 1-1 and the ball screw 1-5 are connected by a coupling 1-1 4. Fixed connection, the connecting nut 1-6 passes through the inner hexagonal hole of the hexagonal mounting frame 1-7, the upper end is threaded with the ball screw 1-5, and the lower end is threaded with the long connecting rod 1-9, and the long connecting rod 1-9 is threaded. The lower end of the rod 1-9 is th...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 Note that the connection nut 1-6 in this embodiment fits in clearance with the inner hexagonal hole of the hexagonal mounting frame 1-7, and the upper end of the movable electrode 2-3 interferes with the lower end of the electrode connector 2-2. The ball screw 1-5, the connecting nut 1-6, the inner hexagon hole of the hexagonal mounting frame 1-7, the long connecting rod 1-9, the electrode connector 2-2 and the movable electrode 2-3 are arranged coaxially. Such setting facilitates the assembly and the up and down movement of the movable electrodes 2-3, and other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Figure 4 Note that the upper planes and lower bottom surfaces of the six inert electrodes 2-5 in this embodiment are not parallel, and the longitudinal thickness gradually increases from the outside to the inside, and reaches the maximum at the contact with the movable electrodes 2-3. Such arrangement facilitates the alignment between the six inert electrodes 2-5 and the micro-components 4-2 and the observation of the shape of the liquid bridge, and the other components and connections are the same as those in the first or second embodiment.

[0019] Specific implementation mode four: combination figure 1 , figure 2 , image 3 and Figure 4 Description, the mounting frame 1-2, two sleeves 1-3, connecting nuts 1-6, hexagonal mounting frame 1-7, six fixing frames 1-8, and electrode connectors 2-2 described in this embodiment All materials are aluminum alloy, the material of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com