Robot body modularization linkage device for single-drive multi-legged robot

A multi-legged robot and linkage technology, applied in the field of robotics, can solve problems such as difficulty in controlling motion characteristics, affecting the precise description of robot kinematics and dynamics mathematics, and complex robot structure, achieving strong practical value, reliability and stability. High and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

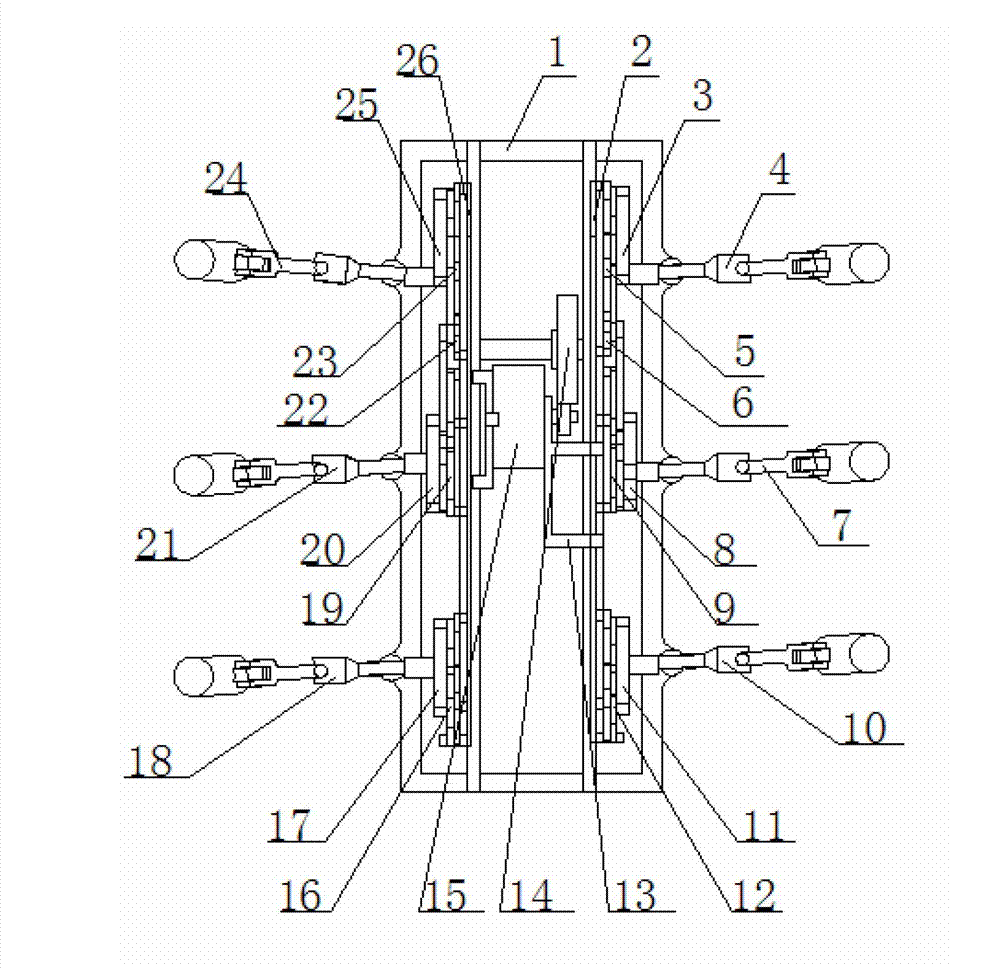

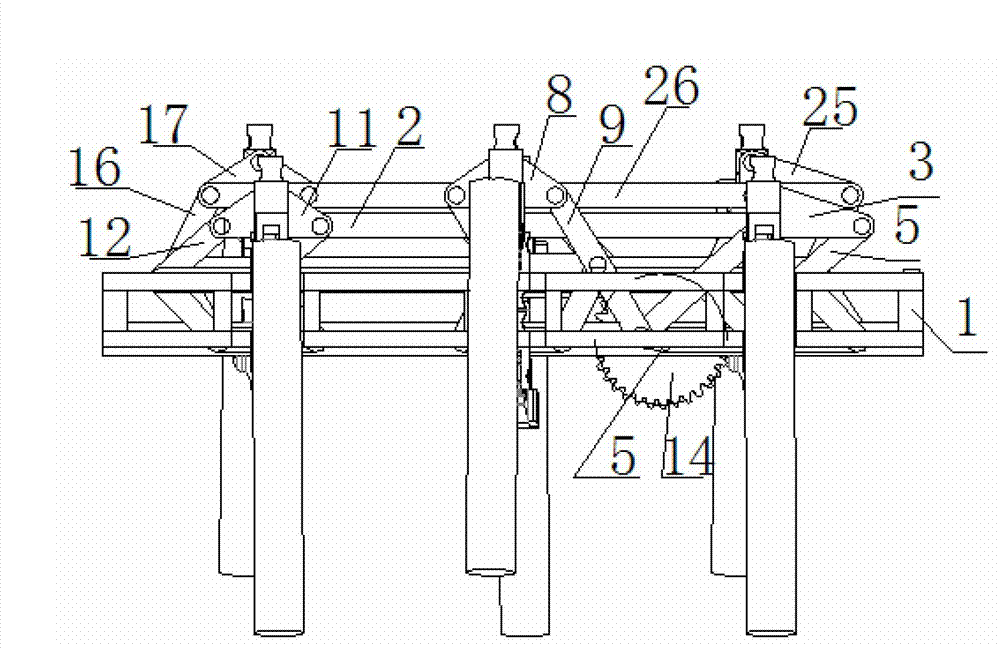

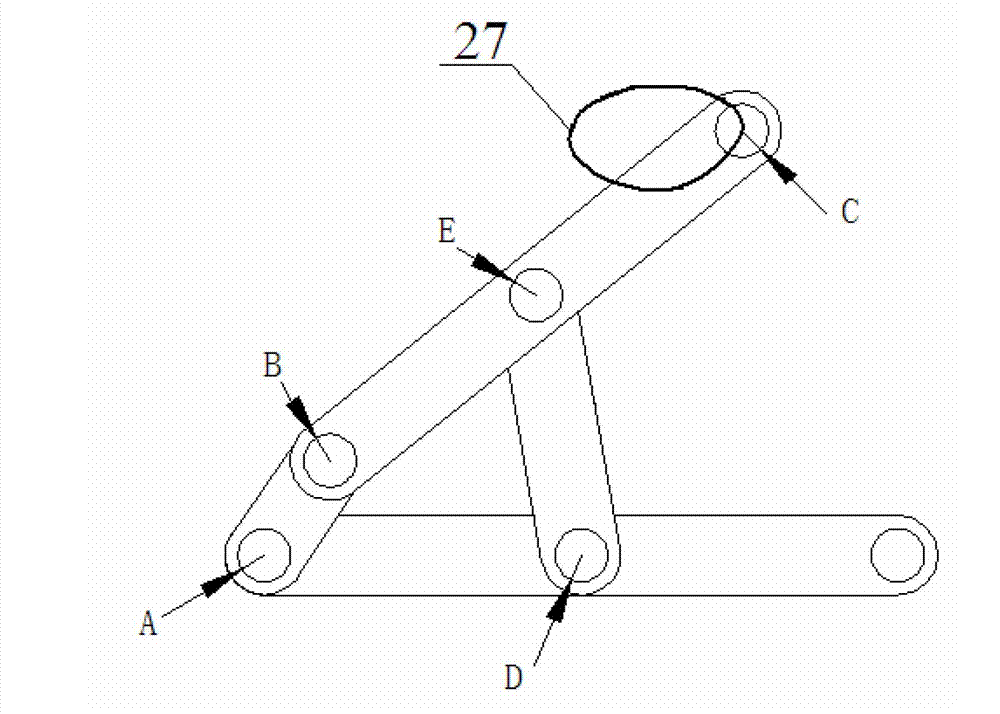

[0038] Single-drive multi-legged robot body modular linkage, such as figure 1 with figure 2 As shown, it includes a main frame 1, a first connecting frame 2 and a second connecting frame 26, the first to sixth grippers 3, 8, 11, 17, 20, 25, the first to sixth hip mechanisms 4, 7, 10, 18, 21, 24, first to sixth double parallelogram linkage mechanisms 5, 9, 12, 16, 19, 23, first crank 6, second crank 22, motor fixing frame 13, power transmission rod 14. Motor 15; motor 15 is fixed on main frame 1 by motor fixing frame 13; first to sixth double parallelogram linkage mechanisms 5, 9, 12, 16, 19, 23 are all arranged on both sides of main frame 1 The first to sixth hip mechanisms 4, 7, 10, 18, 21, 24 are connected to the first to sixth double parallelogram linkage mechanism 5 through the first to sixth grippers 3, 8, 11, 17, 20, 25 , 9, 12, 16, 19, 23 are connected, and the double parallelogram linkage mechanism in front of the same side is connected with the double parallelogram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com