Method for improving transverse displacement quality of railway vehicle and transverse displacement system

A lateral displacement and rail vehicle technology, applied in the field of lateral displacement of rail vehicles, can solve the problems of uneven lateral displacement stress and uneven lateral shear force of elastic vibration damping load-bearing components, and achieves the benefits of lateral swing, reduced damage, and reduced volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

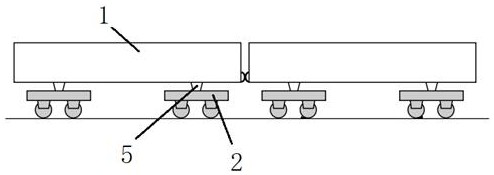

[0037] After research and analysis, the inventor found that the reason why the vehicle tends to be unstable when moving laterally is mainly due to the instability of the elastic damping load-bearing element arranged between the car body and the bogie, and the elastic damping load-bearing element The instability of the vehicle is mainly due to the large transverse shear force generated on the elastic vibration-absorbing bearing element when the vehicle moves laterally, which makes the internal stress uneven and easy to lose stability, which we have not considered before; in fact , the elastic vibration-damping bearing elements are placed on the bogie (as attached figure 1 As shown), it not only bears the weight of the car body, but also provides horizontal displacement for the locomotive when it moves. For example, when the car body passes a curve, the horizontal movement of the car body and the bogie is provided by the elastic vibration-absorbing bearing element. In addition, t...

Embodiment 2

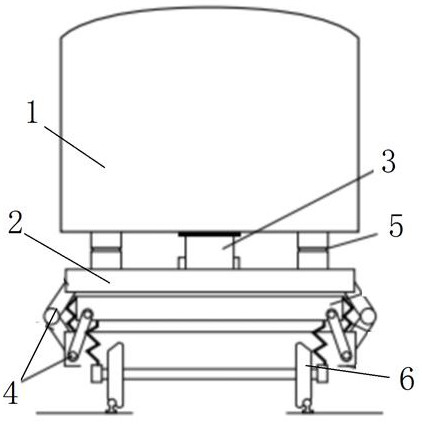

[0062] The principle of embodiment two is the same as that of embodiment one, but the combination structure is slightly different. figure 2 It can be seen that the present invention relates to a lateral displacement system for improving the lateral displacement quality of rail vehicles. The lateral displacement system includes a car body, a center disc, a bogie and an elastic damping bearing element, and the car body is installed on the bogie through the center disc. Between the car body and the bogie, there are a plurality of elastic damping bearing elements arranged around the central pin of the center plate, and the elastic damping of the car body is realized through the elastic damping bearing elements; the elastic damping bearing elements are horizontal, etc. Strain elastic damping bearing element, when the elastic damping bearing element is laterally displaced by the rail vehicle, the lateral displacement between the car body and the bogie is damped through the lateral e...

Embodiment 3

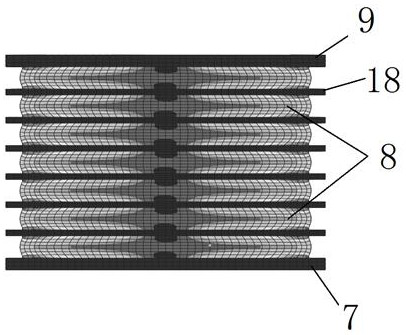

[0065] The principle of the third embodiment is the same as that of the first embodiment, but the combined structure is slightly different, and the attached Figure 8 It can be seen that the present invention relates to a lateral displacement system for improving the lateral displacement quality of rail vehicles. The lateral displacement system includes a car body, a center disc, a bogie and an elastic damping bearing element, and the car body is installed on the bogie through the center disc. Between the car body and the bogie, there are a plurality of elastic damping bearing elements arranged around the central pin of the center plate, and the elastic damping of the car body is realized through the elastic damping bearing elements; the elastic damping bearing elements are horizontal, etc. Strain elastic damping bearing element, when the elastic damping bearing element is laterally displaced by the rail vehicle, the lateral displacement between the car body and the bogie is da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com