Activated sludge reaction system

A technology of reaction system and activated sludge, applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problem of high energy consumption of water inflow, and achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

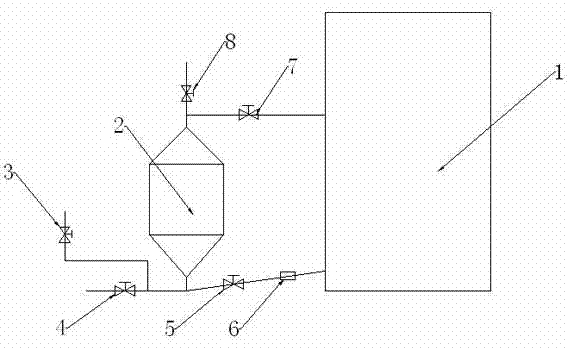

[0042] The activated sludge reaction system described in this embodiment is as figure 1 shown, including:

[0043] Reactor 1, described reactor is normal pressure reactor, and the top of described reactor 1 communicates with atmosphere, and described reactor is high 50m;

[0044] Replacement tank 2, the height of described replacement tank 2 is 6m; Described replacement tank 2 is arranged near the bottom of described reactor 1, is in horizontal position substantially with the high-pressure zone of described reactor 1;

[0045] In communication with the replacement tank 2, an inlet valve 4 for sending untreated sewage into the replacement tank 2 and an outlet valve 3 for releasing the liquid in the replacement tank 2 are provided. The top is provided with an exhaust valve 8; in order to avoid dead ends, the replacement tank 2 in this embodiment includes a cylindrical cylinder and conical cylinders respectively connected to the two bottom surfaces of the cylindrical cylinder. ...

Embodiment 2

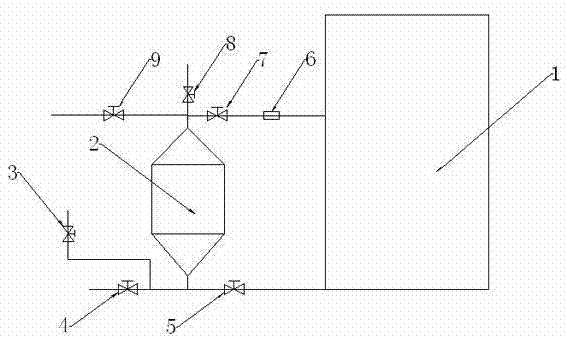

[0053] The activated sludge reaction system described in this embodiment is as figure 2 shown, including:

[0054] Reactor 1, the reactor is a normal pressure reactor, the top of the reactor 1 communicates with the atmosphere, and the reactor is 100m high;

[0055] Replacement tank 2, the height of described replacement tank 2 is lower than the height of described reactor 1, and the height of described replacement tank 2 is 8m; The high pressure zone of the reactor 1 is in a horizontal position;

[0056] In communication with the replacement tank 2, an inlet valve 4 for sending untreated sewage into the replacement tank 2 and an outlet valve 3 for releasing the liquid in the replacement tank 2 are provided. The top is provided with an exhaust valve 8 and a mud discharge valve 9; the replacement tank 2 in this embodiment includes a cylindrical shell and a conical shell respectively connected to the two bottom surfaces of the cylindrical shell. The two tapered barrels gradua...

Embodiment 3

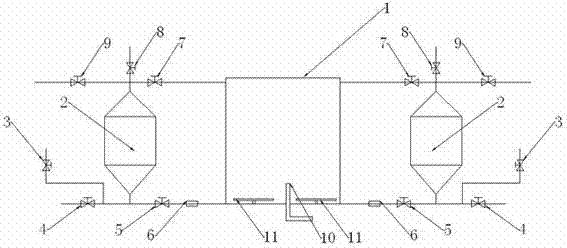

[0065] The activated sludge reaction system described in this embodiment is as image 3 shown, including:

[0066] Reactor, the reactor is a high-pressure reactor, the air pressure in the reactor is 1Mpa, and the reactor is 15m high;

[0067] In this embodiment, a reactor 1 is equipped with two sets of replacement devices, and each replacement device includes:

[0068] Replacement tank 2, the height of the replacement tank 2 is 15m; the replacement tank 2 and the reactor are basically in a horizontal position, and the replacement tank 2 is connected with a water inlet valve 4 and a water outlet valve 3. The top of the replacement tank 2 is provided with an exhaust valve 8 and a mud discharge valve 9; the replacement tank 2 in this embodiment includes a cylindrical shell and conical cones respectively connected to the two bottom surfaces of the cylindrical shell. The barrel body, the two tapered barrel bodies shrink gradually along the direction away from the cylindrical barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com