Heat-insulation fireproof integral wallboard and manufacturing method thereof

A production method and overall technology, applied in thermal insulation, fire prevention, manufacturing tools, etc., can solve the problems of people's life and property hazards, easy fire accidents, wall cracks, etc., and achieve the elimination of people's life and property hazards, saving raw materials and labor , The effect of saving construction land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

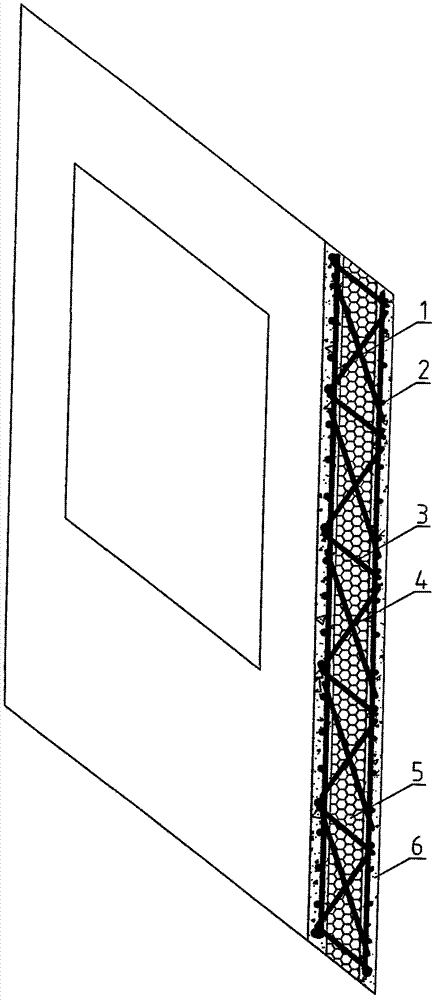

[0026] The longitudinal steel wire 1 of the mesh and the transverse steel wire 2 of the mesh are cold-drawn galvanized steel wires, and their intersections are welded together to form a mesh, and the two meshes are welded together by the straight wire 3 and the cross wire 4 , the straight wire 3 and the cross wire 4 are cold-drawn galvanized steel wires, each mesh is fixedly connected to the concrete layer 6, the mesh is located in the middle of the concrete layer 6, and the concrete layer 6 is fixedly connected to the insulation layer 5, and the insulation layer 5 is One of the inorganic non-combustible materials of foamed cement concrete, expanded perlite, vitrified microbeads, rock wool, and vermiculite powder, the thickness of the concrete layer (6) is not less than 25mm, and the outer surface of the concrete surface layer is embedded with glass fiber mesh Grid cloth, the depth of burial is 3-6mm.

[0027] The production method is:

[0028] 1) Making steel wire mesh frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com