Easy-maintenance axial flow smoke fan with inlet air and outlet air in different directions

An easy-to-maintain, smoke-blower technology, used in mechanical equipment, machines/engines, liquid-fuel engines, etc., can solve the problems of reduced air extraction and exhaust efficiency, inconvenient disassembly and assembly, and harsh working environment, and achieves simple structure and convenient assembly and disassembly. , the effect of large air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

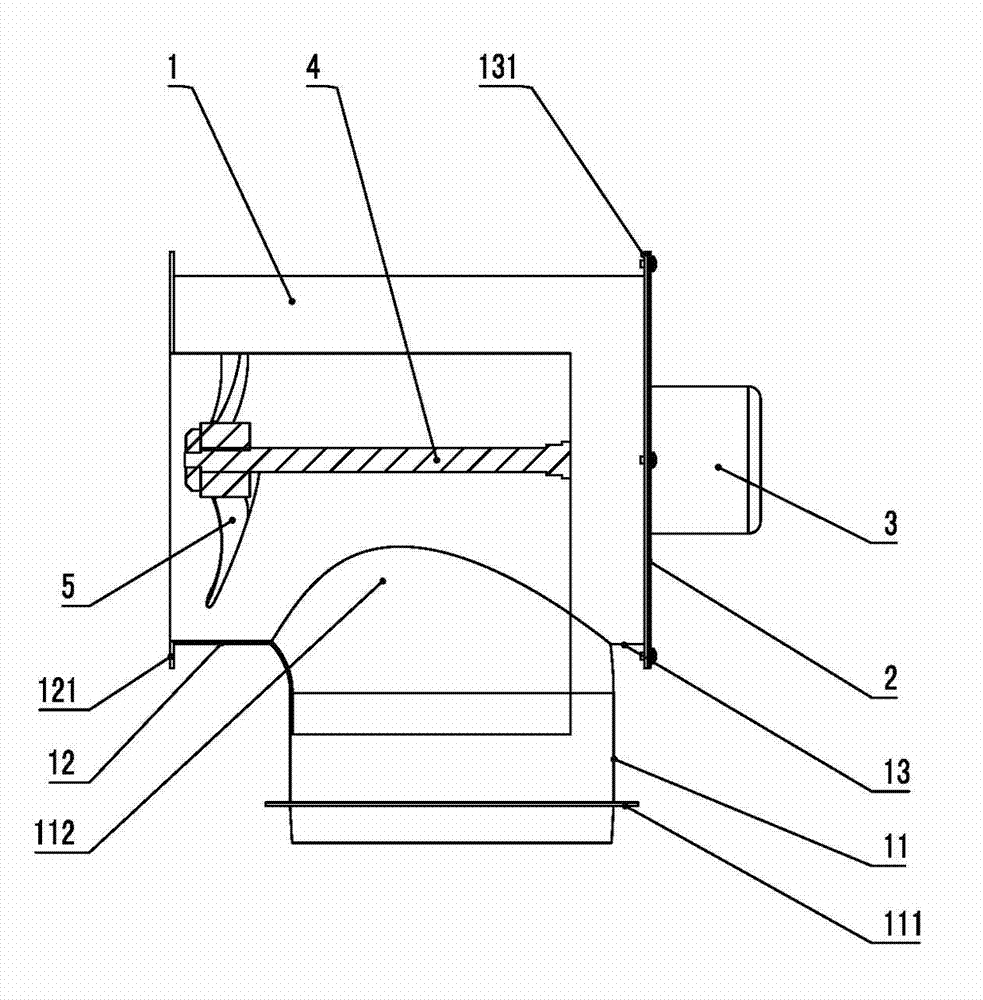

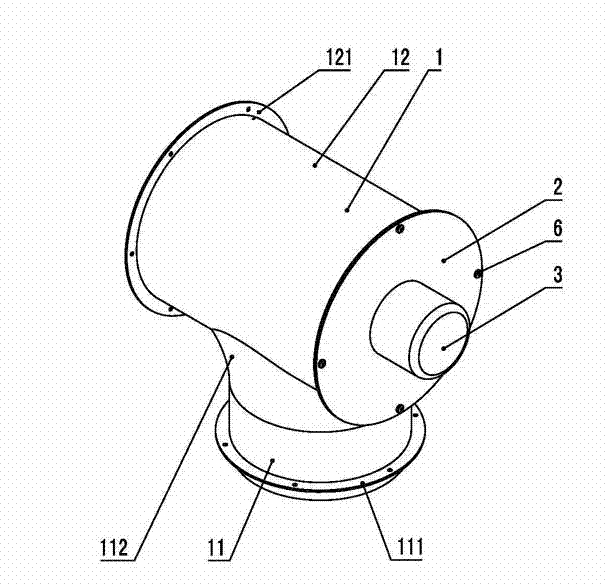

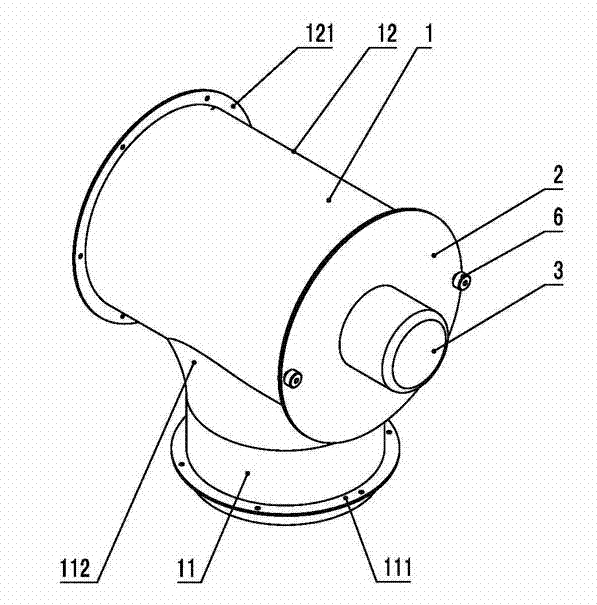

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] Figure 1 to Figure 5 The reference numerals in the figure are: axial flow air cylinder 1; air inlet cylinder 11; air inlet cylinder interface structure 111; curved part 112; exhaust cylinder 12; ; Motor mounting plate 2; Lock slot 21; Motor 3;

[0023] like Figure 1 to Figure 5 As shown, an easy-to-maintain axial-flow oil fume fan with air intake and exhaust in opposite directions includes an axial-flow air cylinder 1, and the axial-flow air cylinder 1 includes an extension cylinder 13, an air inlet cylinder 11 and an exhaust cylinder 12 connected to each other. , the axes of the air inlet tube 11 and the exhaust tube 12 intersect, the extension tube 13 is located at the connection of the air intake tube 11 and the exhaust tube 12, the axis of the extension tube 13 and the exhaust tube The axes of 12 are coincident, the air inlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com