Filter type anti-vacuum oil mist absorbing cover

A vacuum suction and filtration technology, applied in the fields of dispersed particle filtration, engine lubrication, climate sustainability, etc., can solve the problems of oil mist pollution, enlarge the annular cavity, etc., and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

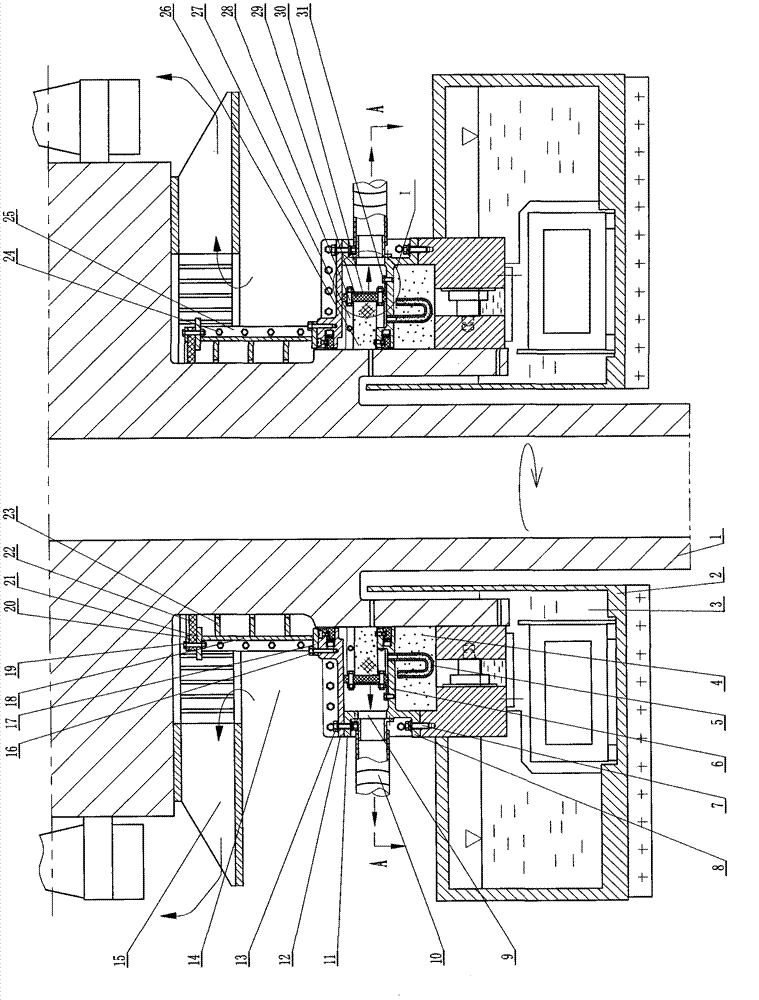

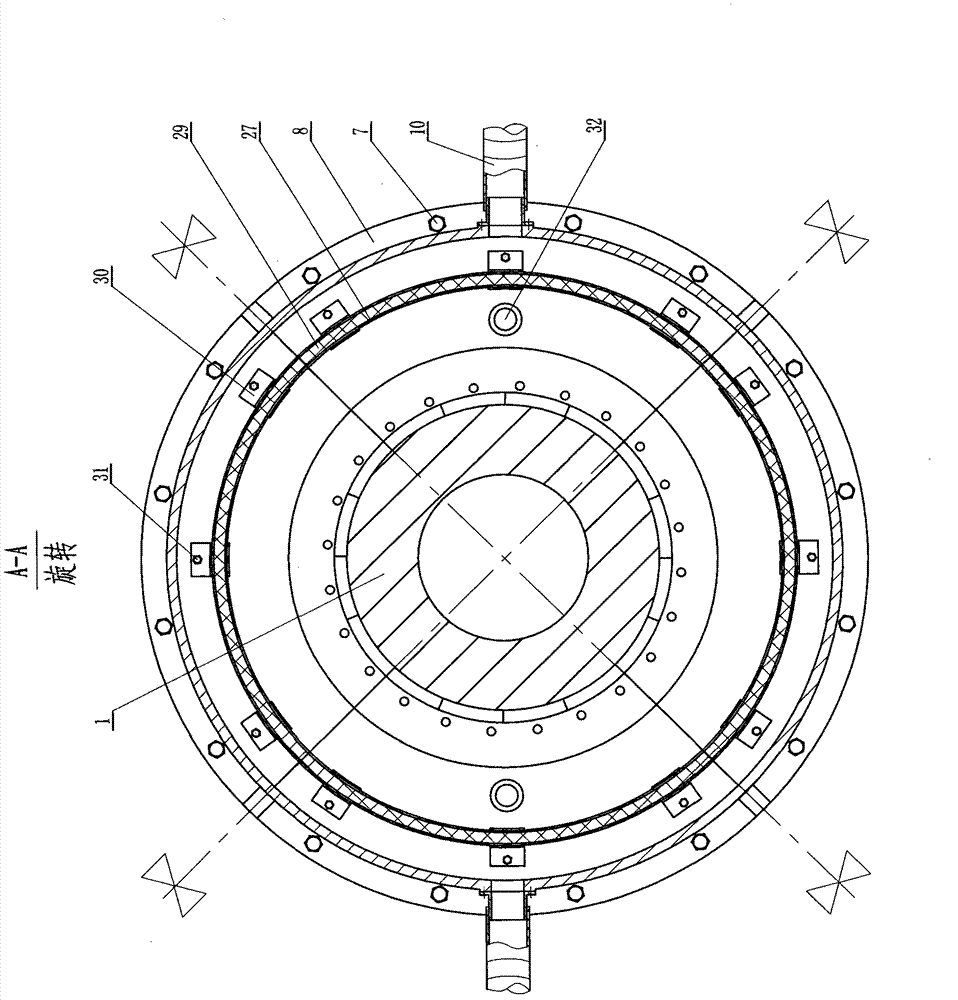

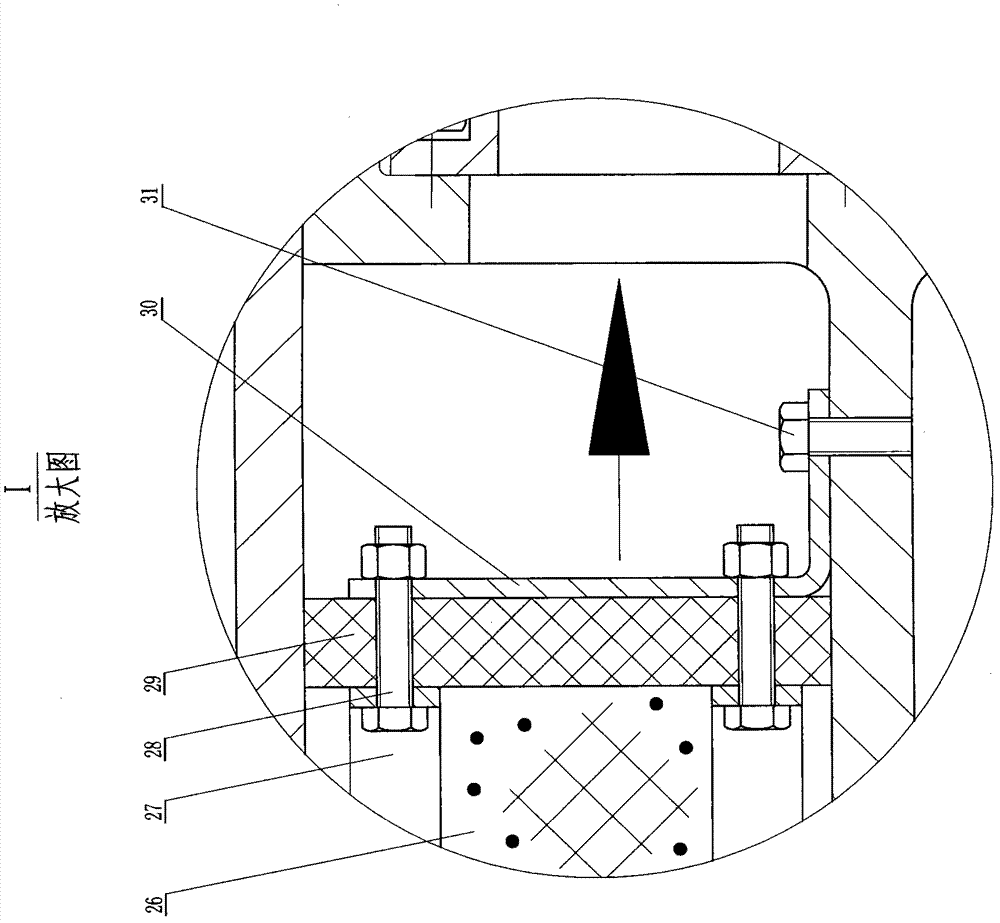

[0021] Use the lower cover fixing bolts (7) to fix the lower packing sealing cover (6) on the upper end of the fixed oil tank (2), and install U type oil return pipe (5), fix a plurality of L-shaped support frames (30) on the same circumference by bracket bolts (31) on the outside of the oil return screw hole (32), and use upper and lower two-layer split pressure ring belts (27 ) and fixing bolts (28) fix the split filter body (29) on the L-shaped support frame (30), and the oil-absorbing mist hole (9) on the outer side of the lower packing sealing cover (6) is equipped with an oil-absorbing mist pipe (10 ). Use the upper flange fixing bolts (13) to fix the upper packing sealing cover (12) on the lower cover upper flange (11). Use the upper annular split pressure ring (20) and the fixing bolts (19) on the split flap to fix the split flap flexible sealing body (22) on the split flap flap (18) upper end, in the split flap flap (18) Internally fixed with multi-layer split retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com