Heat supplying function and air conditioning function switching device of waterway switching heat pump system

A technology of function switching and heat pump system, which is applied in the field of heating and air conditioning function switching device of water circuit switching heat pump system, can solve the problems of undetectable leakage, difficult cleaning, complicated operation, etc., to reduce the difficulty of opening and closing identification, simple operation, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

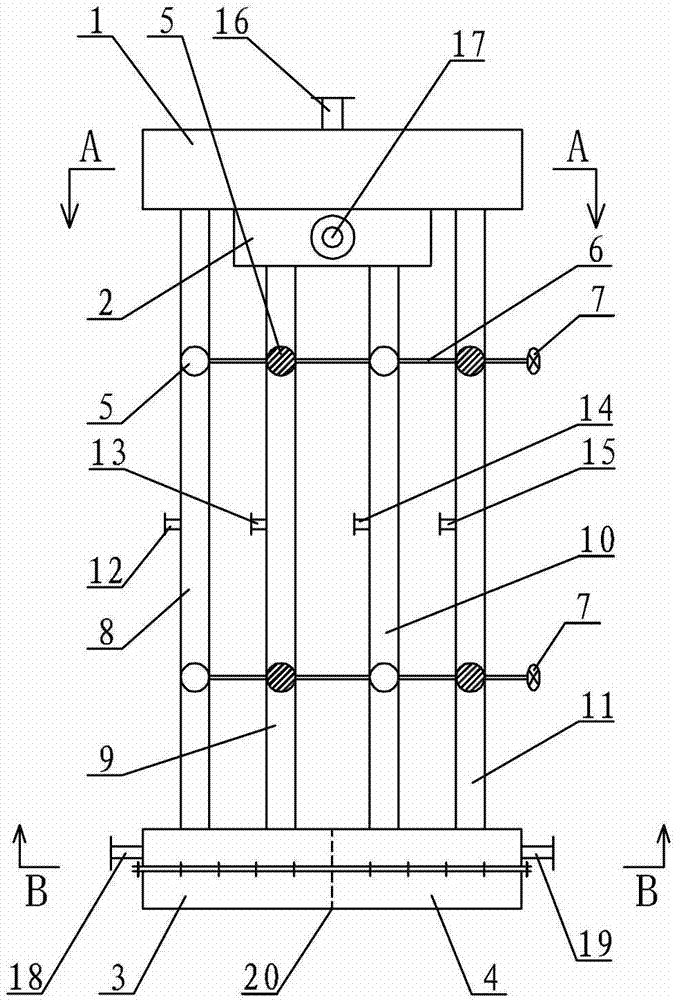

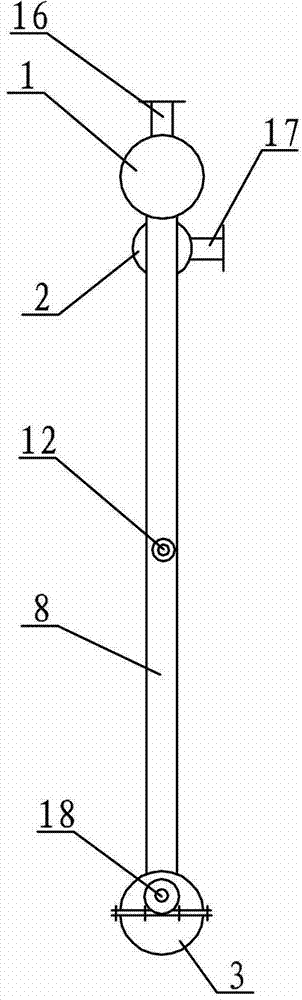

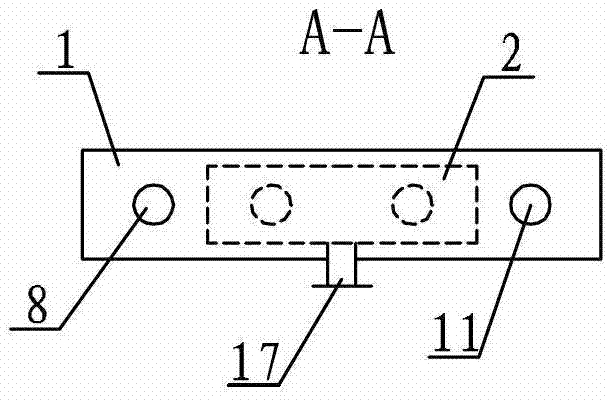

[0010] Specific implementation mode one: combine Figure 1 ~ Figure 4Describe this embodiment, this embodiment includes two function switching devices, each function switching device includes a first water storage tank 1, a second water storage tank 2, a third water storage tank 3, a fourth water storage tank 4, and a first connecting pipe 8 , the second connecting pipe 9, the third connecting pipe 10, the fourth connecting pipe 11, the first drain pipe 12, the second drain pipe 13, the third drain pipe 14, the fourth drain pipe 15, two valve shafts 6, two A hand wheel 7 and eight valves 5, the first water storage tank 1, the second water storage tank 2, the third water storage tank 3 and the fourth water storage tank 4 are respectively provided with a first opening 16, a second opening 17, a first opening 17, and a second opening 17. Three openings 18 and a fourth opening 19, the second water storage tank 2 is arranged below the first water storage tank 1, the first water sto...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination Figure 5 ~ Figure 8 Describe this embodiment, this embodiment includes two function switching devices, each function switching device includes a first water storage tank 1, a second water storage tank 2, a third water storage tank 3, a fourth water storage tank 4, and a first connecting pipe 8 , the second connecting pipe 9, the third connecting pipe 10, the fourth connecting pipe 11, the first drain pipe 12, the second drain pipe 13, the third drain pipe 14, the fourth drain pipe 15, two valve shafts 6, two A hand wheel 7 and eight valves 5, the first water storage tank 1, the second water storage tank 2, the third water storage tank 3 and the fourth water storage tank 4 are respectively provided with a first opening 16, a second opening 17, a first opening 17, and a second opening 17. Three openings 18 and a fourth opening 19, the second water storage tank 2 is arranged below the first water storage tank 1, the first wate...

specific Embodiment approach 3

[0018] Specific implementation mode three: combination Figure 9 ~ Figure 13Describe this embodiment, this embodiment includes two function switching devices, each function switching device includes a first water storage tank 1, a second water storage tank 2, a third water storage tank 3, a fourth water storage tank 4, and a first connecting pipe 8 , the second connecting pipe 9, the third connecting pipe 10, the fourth connecting pipe 11, the first drain pipe 12, the second drain pipe 13, the third drain pipe 14, the fourth drain pipe 15, four valve shafts 6, four A hand wheel 7 and eight valves 5, the first water storage tank 1, the second water storage tank 2, the third water storage tank 3 and the fourth water storage tank 4 are respectively provided with a first opening 16, a second opening 17, a first opening 17, and a second opening 17. Three openings 18 and a fourth opening 19, the second water storage tank 2 and the first water storage tank 1 are arranged side by side...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap