Pressurization-ignited explosive device

A gas pressurization and high-pressure technology, which is applied in blasting and other directions, can solve the problems of no open flames, etc., and achieve the effects of convenient use, cost reduction, and improved blasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

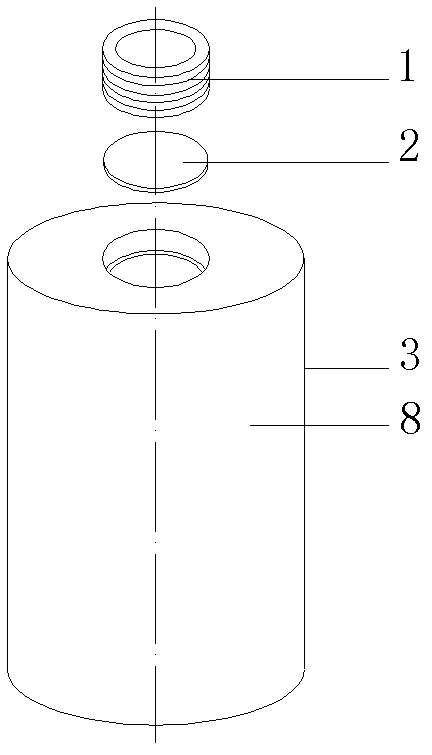

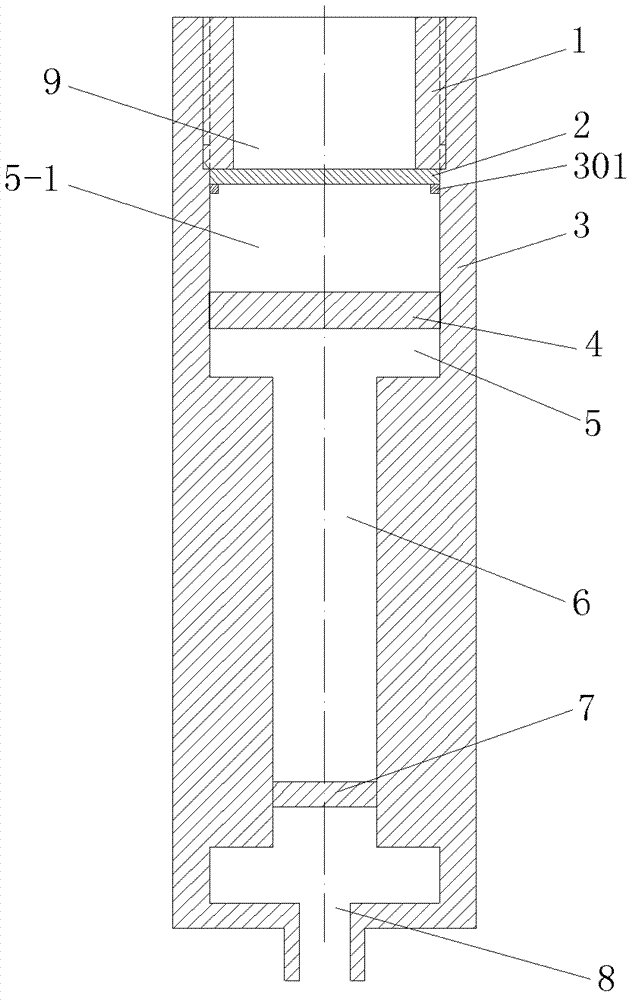

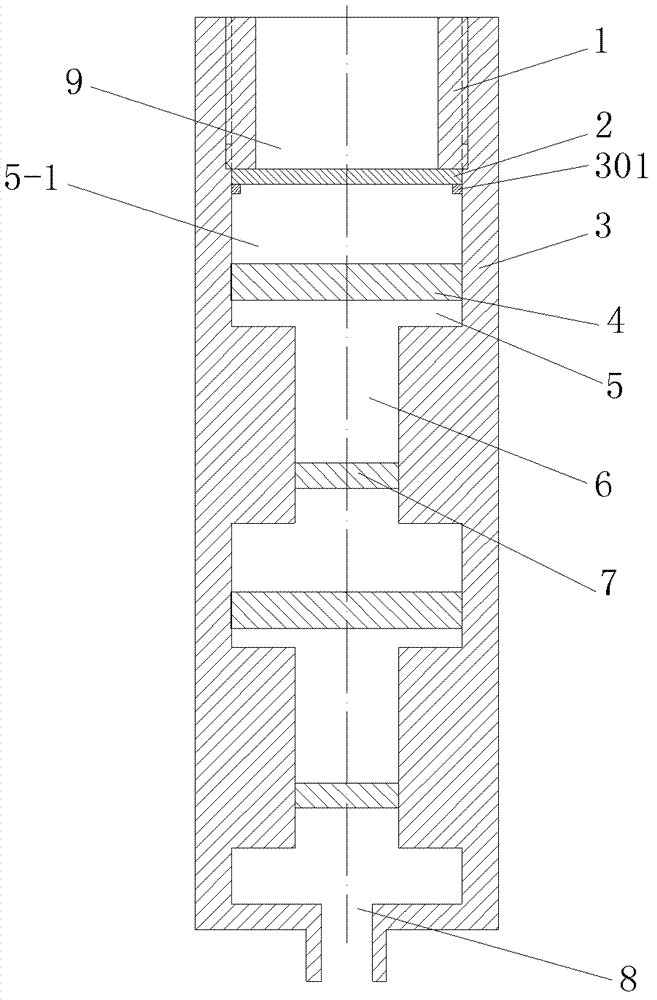

[0019] The structure of the present invention refers to figure 1 , 2 As shown, the figure only shows a specific embodiment of the technical solution of the present invention, and this embodiment does not limit the scope of protection.

[0020] An explosive device for pressurized detonation, consisting of a high-pressure container 3, one end 9 of the high-pressure container 3 is provided with at least one burst disc or a pressure release valve 2, called the first end; the other end is a high-pressure hydraulic fluid or a high-pressure Compressed gas booster end 8 is called the second end; the inside of the high-pressure container 3 is located between the above-mentioned two ends is a piston cylinder cavity, and the piston cylinder cavity is composed of a small diameter cylinder cavity 6 near the second end and The cylinder cavity 5 with a large diameter near the first end is connected and formed; in the above-mentioned two sections of cylinder cavity 6, 5, there are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com