Device and method for detecting micro-electronic packaging process quality based on photo-thermal imaging

一种图像获取装置、成像的技术,应用在测量装置、采用光学装置、光学测试瑕疵/缺陷等方向,达到降低刚度要求、检测评估可靠、结果可靠的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

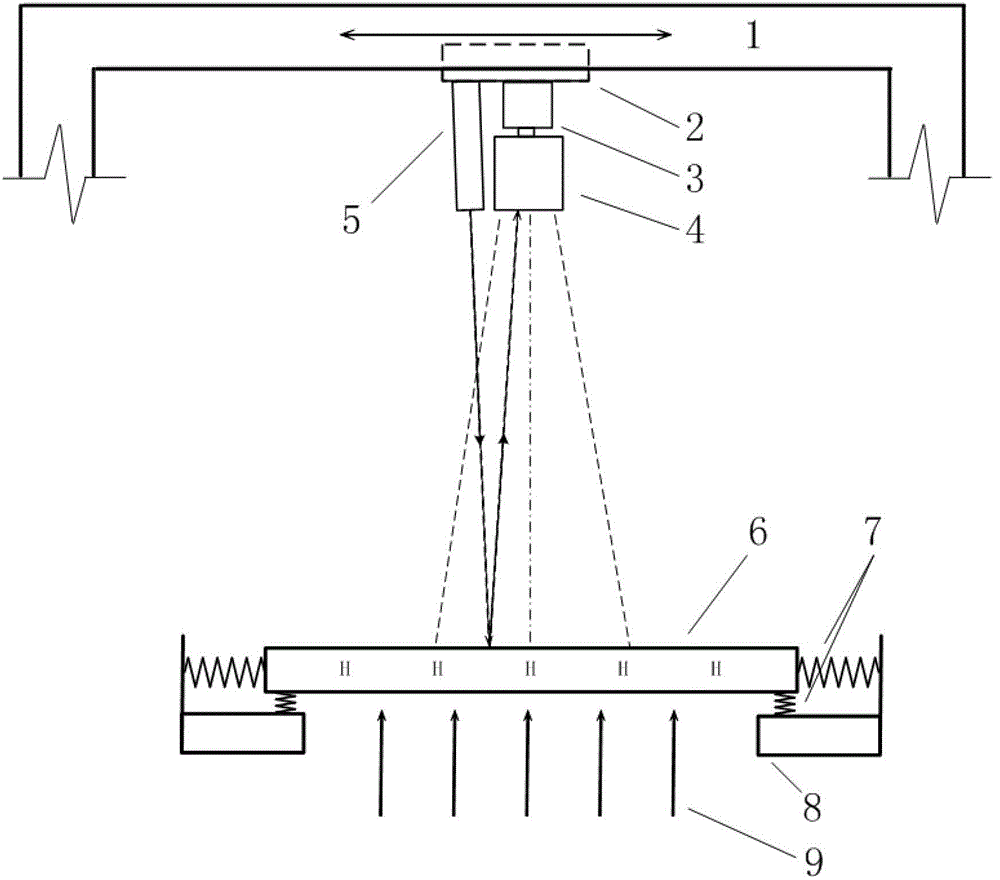

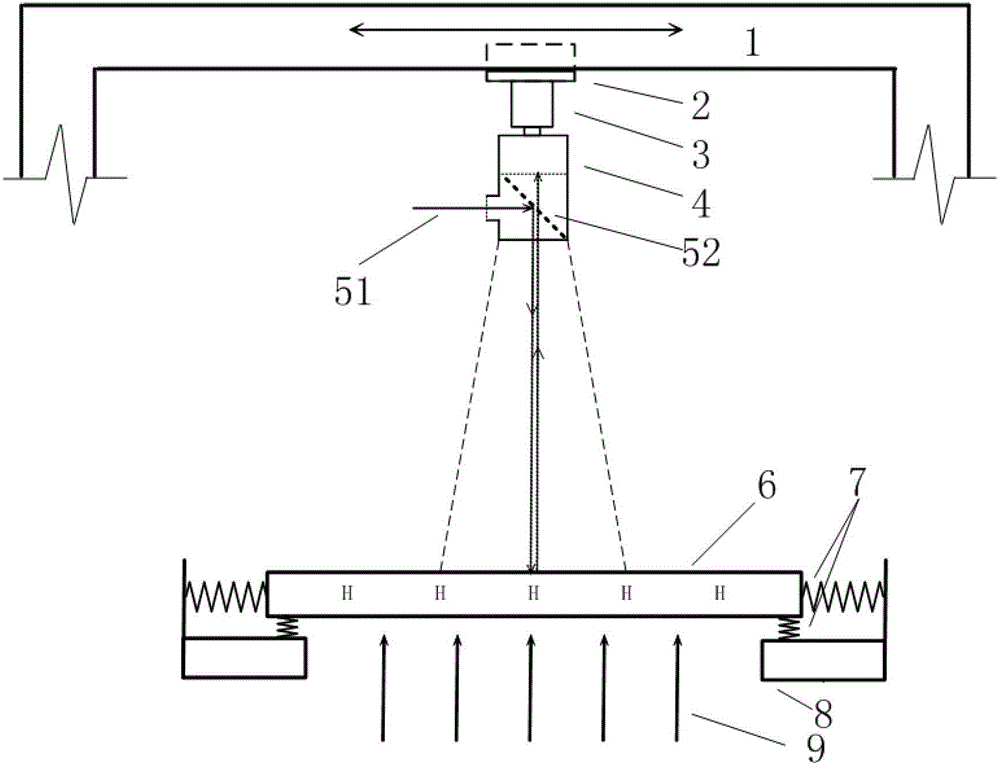

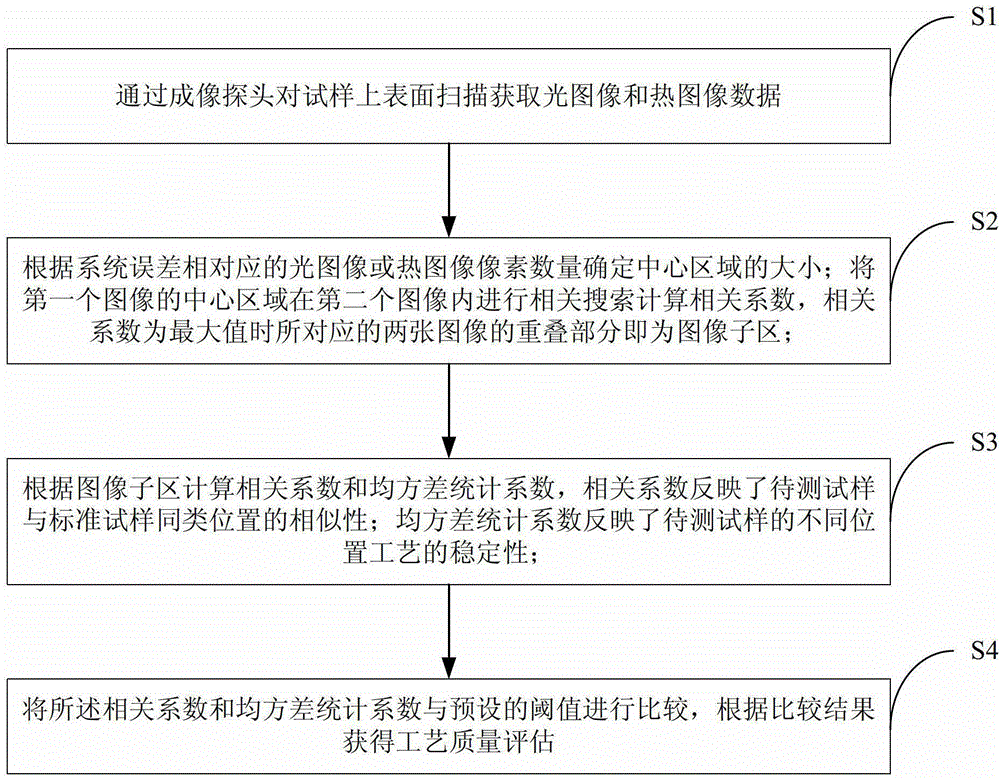

[0030] The invention provides a microelectronic packaging process quality detection device based on photothermal imaging, which can detect the process quality at different stages in the microelectronic packaging process flow; it is especially suitable for flip-chip, wafer-level packaging and three-dimensional integrated circuits based on silicon vias The quality inspection of semi-finished products and finished products at each stage of the process flow of packaging technology can also be used in advanced packaging processes such as embedded system-in-package, which helps to improve product yield an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com