Device for correcting parallelism degree of laser emission optical axis and capturing and tracking visual axis

A correction device and laser emission technology, applied in the direction of using optical devices, measuring devices, optics, etc., can solve the problems of many labor costs, limited measurement accuracy, low work efficiency, etc., and achieve convenient and flexible operation, small space volume, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

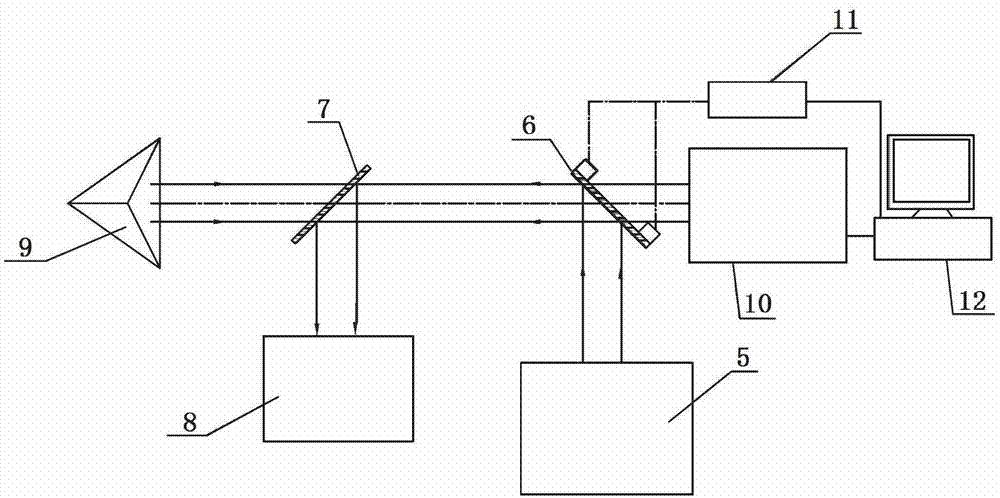

[0022] Specific embodiments: the present invention is image 3 The structure shown is implemented, in which the laser 5 adopts a laser transmitter of any wavelength band, the two-dimensional swing mirror 6 is coated with optical coating to form a semi-reflective and semi-transparent optical plane mirror, and the two-dimensional swing mirror controller 11 adopts a DSP digital control circuit to split the beam. The mirror 7 is coated with optical coating to form a semi-reflective and semi-transparent optical plane mirror, the laser energy collector 8 uses a black body collector to collect laser energy, and the corner cube prism 9 is made of K9 optical glass to make three equal cone angles, and the error of the glass angle can be precisely processed To within 1 arcsecond, the CCD camera 10 employs an infrared camera.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com