Device and method for measuring coaxiality of trunnions of converter backing ring

A technology for measuring the coaxiality and converter ring, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of difficult measurement of the coaxiality of the trunnion, and achieves a method that is easy to quantitatively judge, easy to manufacture, and to ensure correctness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

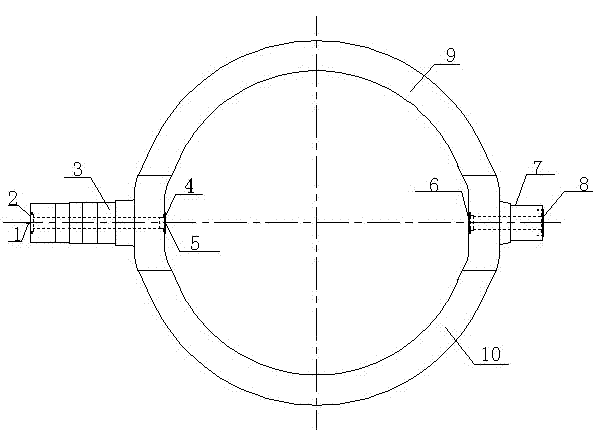

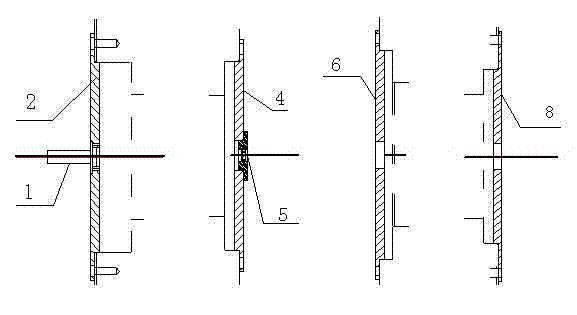

[0020] Depend on figure 1 , figure 2 It can be seen that the converter support ring trunnion coaxiality measurement device is composed of the transmission side trunnion 3 , the tapping side sector 9 , the swimming side trunnion 8 and the feeding side sector 10 by welding. The coaxiality measuring device is arranged on the supporting ring. It can further be seen that the outer end of the transmission side trunnion 3 is provided with a launch bracket 2, and the laser collimator 1 is fixed on the launch support; the inner end of the transmission side trunnion is provided with a launch target support 4, and the target target 5 is fixed on the launch target support. The inner end of the trunnion 8 on the swimming side is provided with an inner receiving target bracket 6, and the target target is fixed on the inner receiving target bracket; the outer receiving target bracket 8 is arranged on the outer side of the swimming side trunnion, and the target target is fixed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com