Adaptive redundant lifting wavelet noise reduction analysis-based bearing failure recognition method

A wavelet noise reduction and fault identification technology, applied in mechanical bearing testing, etc., can solve problems such as difficult to match signal features, achieve optimal matching and extraction, ensure integrity, and filter out noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

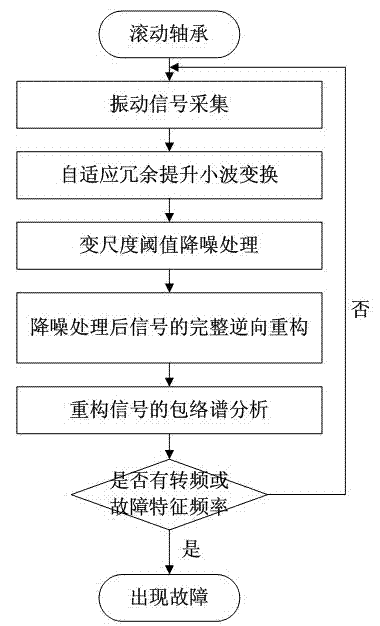

[0019] Refer to attached figure 1 , the overall analysis of the bearing vibration signal includes four specific steps:

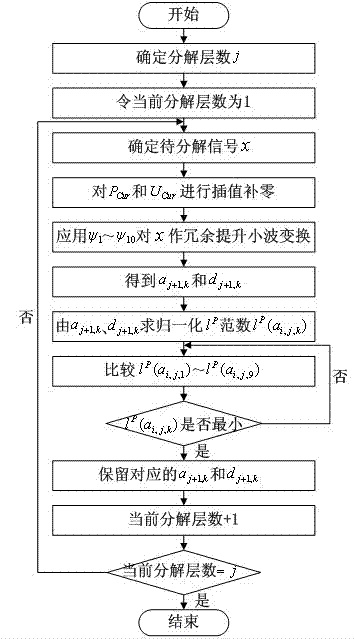

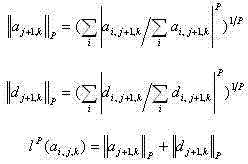

[0020] 1) Determine the number of decomposition layers to be three, and perform adaptive redundant lifting wavelet transform on the collected bearing vibration signals; after the three-layer decomposition is completed, three low-frequency approximation signals are obtained and three high-frequency detail signals and ; where the subscript Respectively represent the results of the decomposition of the first layer, the second layer and the third layer;

[0021] 2 pairs and Scale-variable threshold noise reduction processing; in this process, the initial threshold is first generated by the heuristic threshold generation rule and the initial vibration signal , and then choose a hard threshold function for and Threshold a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com