Attenuation slice placing device

An attenuator and mounting base technology, applied in the laser field, can solve the problems affecting the beam quality and the interference fringes of the outgoing light spot, and achieve the effect of accurate light spot information, eliminating background and noise, and shielding stray light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

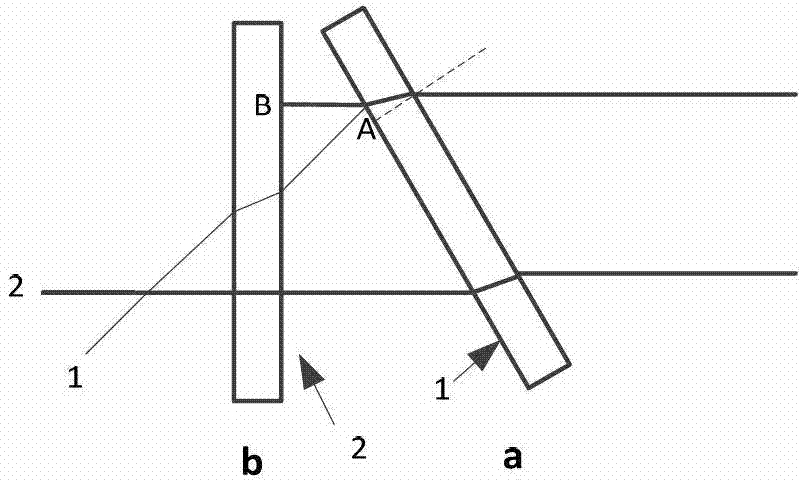

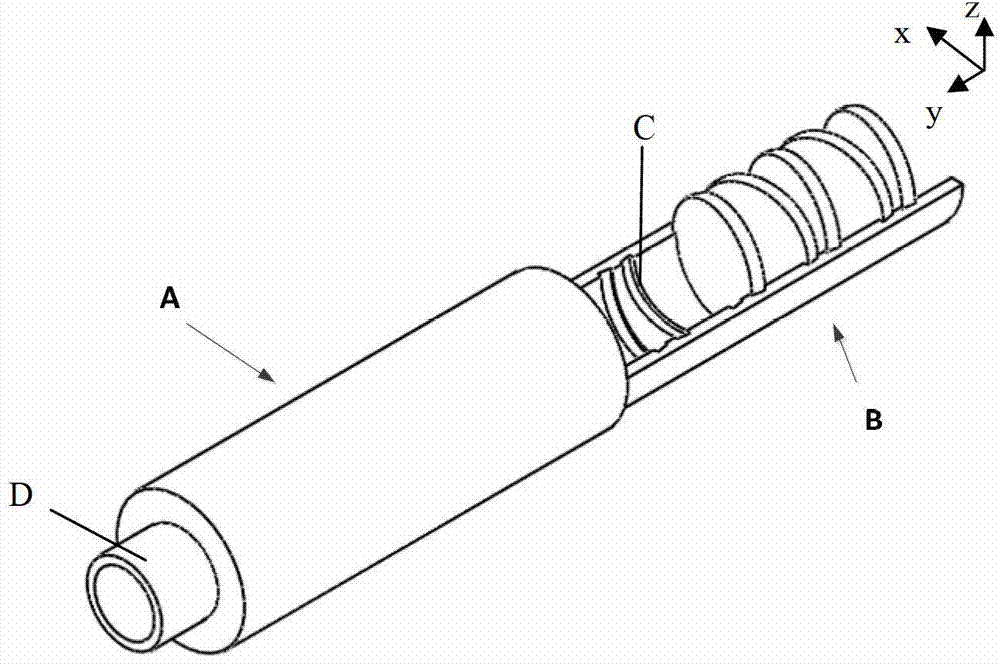

[0024] image 3 A three-dimensional schematic diagram showing an attenuation sheet placement device according to an embodiment of the present invention, such as image 3 As shown, the attenuation sheet placement device includes a sleeve A and a drawer-shaped mounting seat B installed in the sleeve A. The mounting seat B can be drawn out and pushed in along the axis of the sleeve A, so that it can be conveniently quickly replace the attenuator according to actual needs, Figure 4 A three-dimensional schematic view of the installation seat B being pushed into the sleeve A is shown. In one embodiment, along the length direction of the mounting base B, the inner surface of the mounting base B is sequentially provided with multiple (at least two) grooves C for placing attenuation sheets, so that multiple attenuation sheets form a stage couplet. Each groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com