Plastic lens

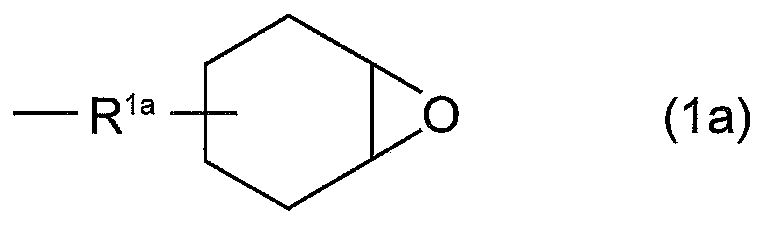

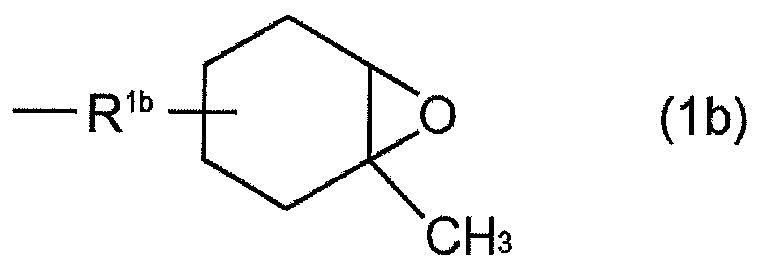

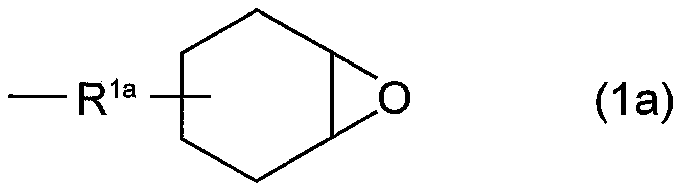

A plastic lens, resin technology, applied in thin material processing, glasses/goggles, epoxy resin coatings, etc., can solve the problems of mechanical properties reduction, discoloration, increase, etc., to achieve high surface hardness, excellent cost performance, and interference fringes. produce a suppressive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0316] Preparation Example 1: Preparation of Hard Coating Solution 1 and Evaluation of Surface Hardness and Scratch Resistance of Hard Coating Film

[0317] Drop into 2-(3,4-epoxycyclohexyl) ethyltrimethoxysilane 277.2 millimoles in 1000 milliliters flasks (reaction vessel) that thermometer, stirring device, reflux condenser and nitrogen inlet tube are installed under nitrogen flow ( 68.30 g), 3.0 mmol (0.56 g) of phenyltrimethoxysilane, and 275.4 g of acetone, and the temperature was raised to 50°C. To the thus obtained mixture was added dropwise 7.74 g (2.8 mmol as potassium carbonate) of a 5% potassium carbonate aqueous solution over 5 minutes, and then 2800.0 mmol (50.40 g) of water was added dropwise over 20 minutes. It should be noted that no significant temperature rise occurred during the dropwise addition. Then, polycondensation reaction was carried out for 5 hours under a nitrogen stream while maintaining 50°C.

[0318] Then, 137.70 g of methyl isobutyl ketone and...

preparation example 2

[0341] Preparation Example 2: Preparation of Hard Coating Solution 3 and Evaluation of Surface Hardness and Scratch Resistance of Hard Coating Film

[0342] Using 75 g of a colorless and transparent liquid product (low molecular weight polyorganosilsesquioxane containing alicyclic epoxy group) containing 25% by weight of methyl isobutyl ketone produced in Preparation Example 1, in order to increase the molecular weight Perform the following operations.

[0343] In a 1000 ml flask (reaction vessel) equipped with a thermometer, a stirring device, a reflux condenser, and a nitrogen gas introduction tube, the low molecular weight polyorganosilsesquisil containing alicyclic epoxy group obtained in Preparation Example 1 was charged under nitrogen flow. Oxane mixture (75g), with respect to the net content (56.2g) of the low molecular weight polyorganosilsesquioxane containing alicyclic epoxy group, add potassium hydroxide 100ppm (5.6mg), water 2000ppm (112mg), After heating at 80°...

Embodiment 1

[0353] Example 1: Manufacture of hard-coated lens 1 and evaluation of interference fringes

[0354] (Preparation of Hard Coating Solution 4)

[0355] Into a 500cc brown sample bottle, 54.7 g of low molecular weight polyorganosilsesquioxane containing alicyclic epoxy groups obtained by the same method as Preparation Example 1 [41 g as a substance containing 25% by weight of MIBK], Product name "SAN-AID SI-100" (manufactured by Sanshin Chemical Industry Co., Ltd., thermal cationic polymerization initiator) 1.0 g, product name "SurflonS-243" (manufactured by AGC SEIMI CHEMICAL, fluorine-based leveling agent) 0.25 g , and 150 g of ethyl acetate were stirred and mixed with a vibrator to prepare a curable composition (hard coating liquid 4).

[0356] (Creation of hard-coated lens 1)

[0357] A lens mold was installed in an injection molding machine (Tuparl TR150S manufactured by Sodic Plastech Co., Ltd.), and a transparent nylon resin (TROGAMID CX7323 manufactured by Daicel-Evon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com