Highly adhesive multilayer thermoplastic resin film

A thermoplastic resin film, easy-to-adhesion technology, applied in synthetic resin layered products, layered products, nanotechnology, etc., can solve problems such as poor adhesion, achieve excellent adhesion, suppress interference fringes, and resist chemicals The effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] PET pellets (intrinsic viscosity 0.63dl / g) without external particles are fully vacuum-dried and supplied to the extruder, melted at a temperature of 285°C, extruded into a sheet form from a T-die, and applied static electricity The tape casting method is wound on a mirror casting drum with a surface temperature of 25°C and allowed to cool and solidify. The unstretched film thus obtained was heated to a temperature of 88° C. and stretched 3.3 times in the longitudinal direction to prepare a uniaxially stretched film. This uniaxially stretched film was subjected to corona discharge treatment in air, and the following laminated film forming coating liquid was coated on the treated surface. The uniaxially stretched film coated with the coating solution for forming a laminated film is held in a preheating zone by clamps, dried at a temperature of 95°C, and then continuously stretched in the width direction in a heating zone at a temperature of 110°C. Stretching 3.4 times, ...

Embodiment 2

[0129] A laminated PET film was obtained in the same manner as in Example 1, except that the following laminated film-forming coating liquid was used instead of the laminated film-forming coating liquid used in Example 1.

[0130] "Laminated film forming coating solution"

[0131] - The coating liquid A1, the coating liquid B1, and the coating liquid C1 used the same thing as Example 1.

[0132] The above-mentioned coating solution A1 and coating solution B1 were mixed at a solid content weight ratio, coating solution A1 / coating solution B1 = 30 / 70, and 100 parts by weight of coating solution C1 was mixed with respect to 100 parts by weight to prepare a laminated film forming coating. liquid. In this case, the solid content weight ratio of each coating liquid was coating liquid A1 / coating liquid B1 / coating liquid C1=30 / 70 / 100.

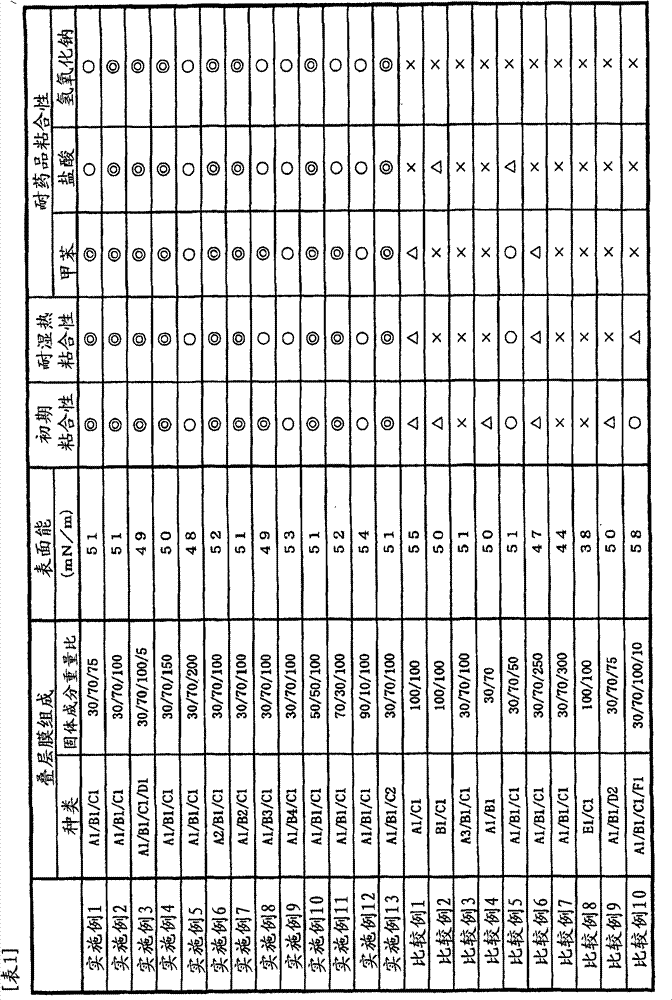

[0133] The results are shown in Table 1. Excellent initial adhesion, heat-and-moisture resistance, and chemical-resistant adhesion.

Embodiment 3

[0135] A laminated PET film was obtained in the same manner as in Example 1, except that the following laminated film-forming coating liquid was used instead of the laminated film-forming coating liquid used in Example 1.

[0136] "Laminated film forming coating solution"

[0137] - The coating liquid A1, the coating liquid B1, and the coating liquid C1 used the same thing as Example 1.

[0138] · Coating solution D1:

[0139] A coating solution obtained by diluting an oxazoline-based crosslinking agent ("EPOCROS" WS-300 manufactured by Nippon Catalyst Co., Ltd.) with water.

[0140] The above-mentioned coating solution A1 and coating solution B1 were mixed according to the weight ratio of solid components, coating solution A1 / coating solution B1 = 30 / 70, and 100 parts by weight of coating solution C1 and 5 parts by weight of coating solution D1 were mixed with respect to 100 parts by weight. A laminated film forming coating solution was prepared. In this case, the solid co...

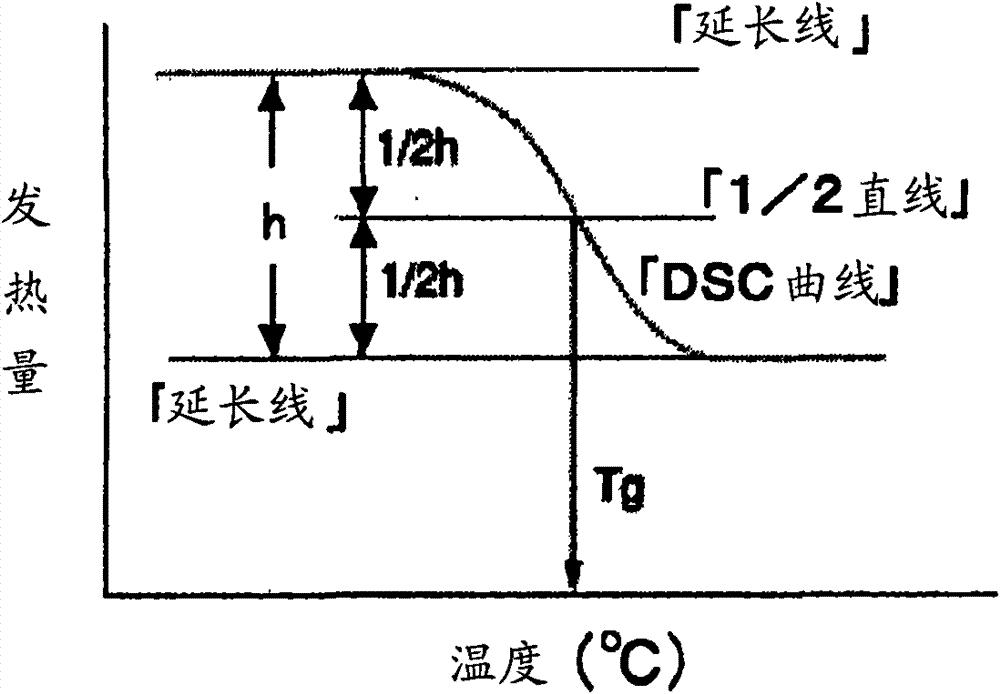

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com