Motor loading device

A technology of loading device and loading motor, applied in electrical testing/monitoring and other directions, can solve problems such as labor, coupling damage, motor damage, etc., and achieve the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below with reference to the accompanying drawings.

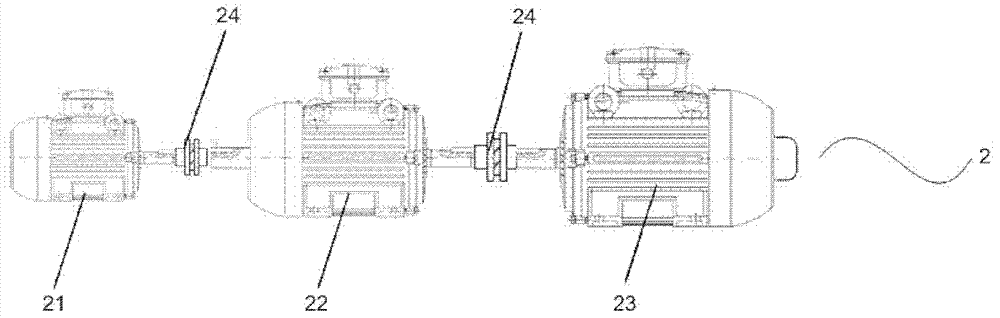

[0029] figure 2 is a schematic diagram of the mechanical part of the motor loading device according to an embodiment of the present invention. As shown in the figure, the motor loading device 2 according to the embodiment of the present invention includes three motors 21 , 22 , 23 connected in series through a coupling 24 . It should be noted that the motor loading device of the present invention may include four, five or more motors, not limited to three as an example here. However, from the perspective of the complexity of the motor mechanical connection and electrical control, preferably, the motor loading device of the present invention includes three or four motors, so as to avoid causing the motor control system to be relatively complicated and / or difficult to ensure that the motors are connected at the same time. axis.

[0030]The three motors 21, 22, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com