Variable displacement lubricant pump

A lubricant pump and lubricant technology, applied in the field of lubricant pumps, can solve the problems of inappropriate lubricant flow rate, disturbance of balance force, unsuitability for engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

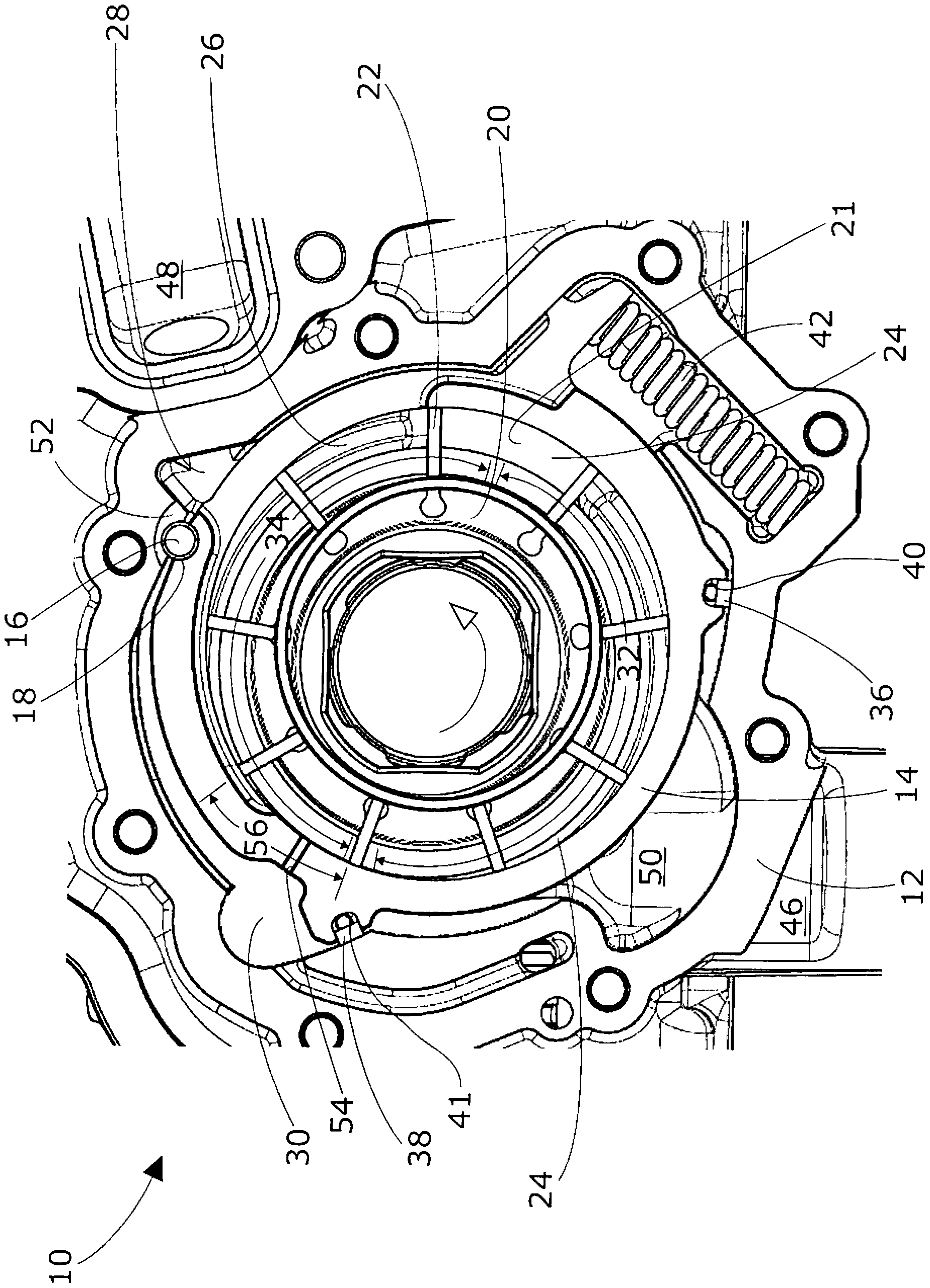

[0017] exist figure 1 In , a variable displacement lubricant pump 10 for an internal combustion engine is shown. The lubricant pump 10 is adapted to supply lubricant to an internal combustion engine, more specifically, to supply lubricant to an internal combustion engine with a lubricant discharge pressure which should not be proportionally dependent on the rotational speed of the pump.

[0018] The variable displacement lubricant pump 10 comprises a metal housing 12 in which a displaceable control ring 14 is arranged axially between two side walls (not shown). The control ring 14 has a pivot 16 about which the control ring 14 pivots such that the control ring 14 is displaced between low and high pumped volume directions. The pivot 16 is realized by a fulcrum pin 18 .

[0019] The metal housing 12 contains a pump rotor 20 having a number of radially slidable vanes 22 whereby the slidable vanes 22 rotate inside a displaceable control ring 14 . The control ring 14 encloses a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com