Lubricating oil vane pump

A technology of lubricating oil and vane pump, which is applied in the direction of pressure lubrication, pressure lubricant, and engine lubrication of lubricating pumps, and can solve problems such as reducing the efficiency of lubricating oil vane pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

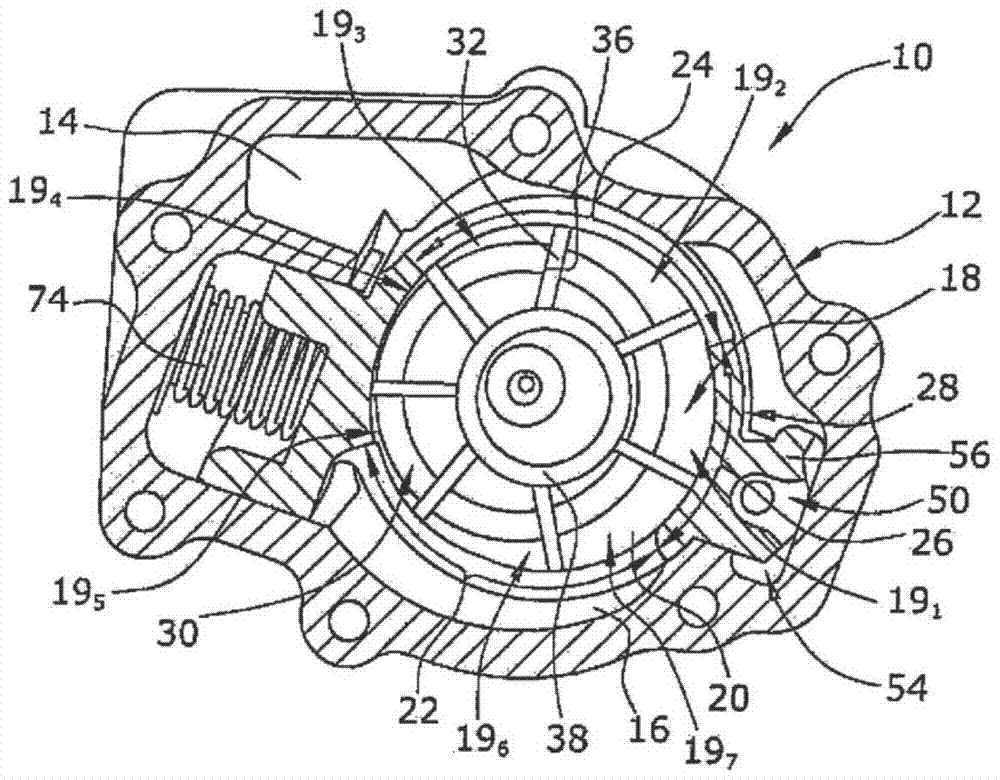

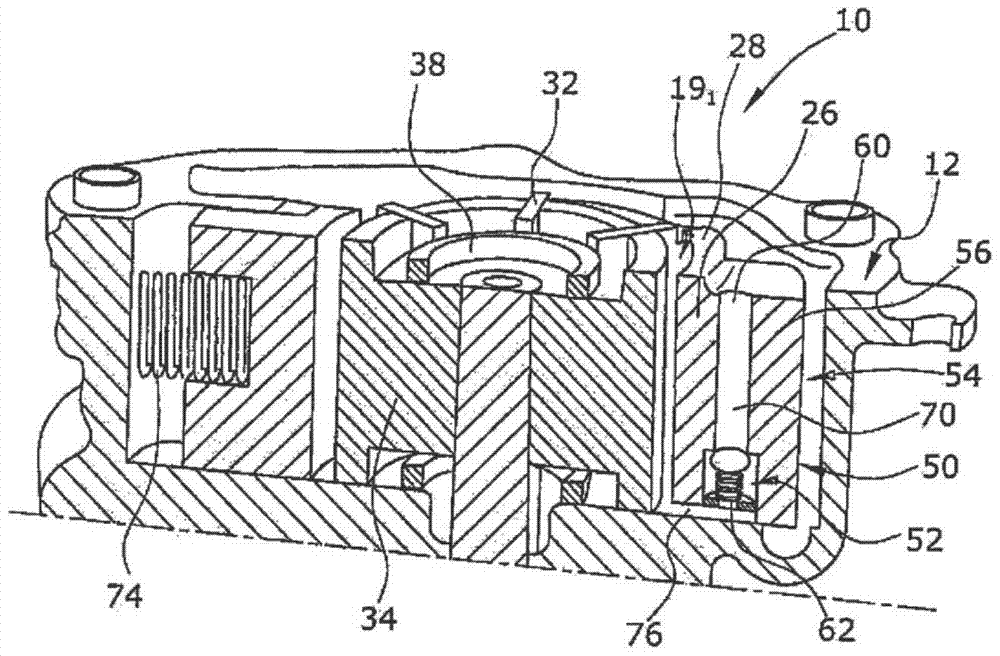

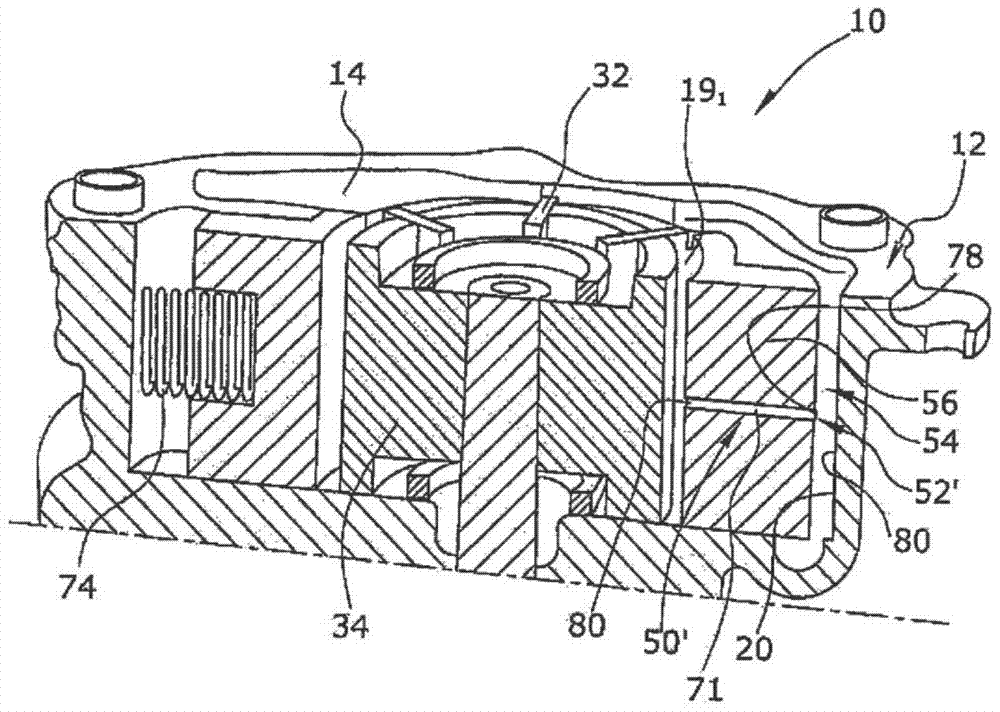

[0027] The drawing shows a lube oil vane pump 10 as part of a pump system for supplying pressurized lube oil to an internal combustion engine. The lubricating oil vane pump 10 pumps lubricating oil with pump outlet pressure to the internal combustion engine and is driven by the engine.

[0028] The lubricating oil vane pump 10 includes a pump housing 12 having a pump inlet chamber 16 and a pump outlet chamber 14 , wherein the housing 12 also includes two chamber side walls 20 covering the pump chamber 18 . The pump housing 12 also defines a pump inlet chamber 16 for drawing oil from the oil tank and a pump outlet chamber 14 for supplying oil at pump outlet pressure to the engine. The pump chamber 18 is divided in the circumferential direction into a filling region 22 connected to the pump inlet chamber 16 , a discharge region 24 connected to the pump outlet chamber 14 and an intermediate region 26 between the filling region 22 and the discharge region 24 .

[0029] In the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com