Light-sensitive solder resist ink for LED (Light Emitting Diode) backlight source

A technology of photosensitive solder resist ink and LED backlight, which is applied in the field of circuit board manufacturing, can solve the problems that cannot meet the high reflectivity of photosensitive ink of LED backlight, and achieve the effect of improving the reflectivity and uniformity of reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

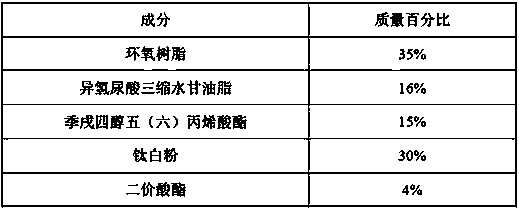

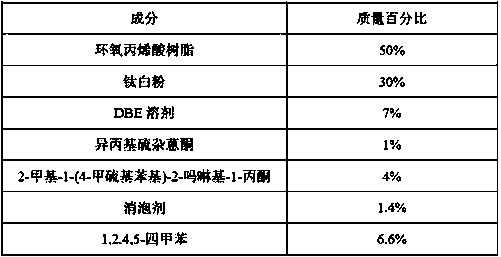

[0012] A photosensitive solder resist ink for LED backlight, which is composed of a main agent and a hardener (curing agent) in a mass ratio of 3:1.

[0013] The main agent described in the embodiment of the present invention consists of epoxy acrylic resin, titanium dioxide, DBE solvent, isopropyl thioxanthone, 2-methyl-1-(4-methylthiophenyl)-2-morpholinyl -1-Acetone, defoaming agent, 1,2,4,5-tetramethylbenzene, in which the mass proportion of each component is epoxy acrylic resin 50%, titanium dioxide 30%, DBE solvent 7%, isopropyl Thioxanthone 1%, 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone 4%, defoamer 1.4%, 1,2,4,5- Tetramethylbenzene 6.6%.

[0014] The preparation method of the epoxy acrylic resin is: weighing epoxy resin, acrylic acid, N,N-diethylbenzylamine and p-hydroxyanisole according to the mass percentages of 73.8%, 52.3%, 0.8%, and 0.1% respectively As a synthetic raw material, first dissolve the catalyst N,N-diethylbenzylamine and the polymerizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com