Speed change device for revolving mop

A technology of rotating mop and speed change device, which is applied in the direction of cleaning carpets, floors, cleaning equipment, etc. It can solve the problems of increased manufacturing cost, complex structure, and low utilization rate, and achieves convenient operation and use, simple and compact structure, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

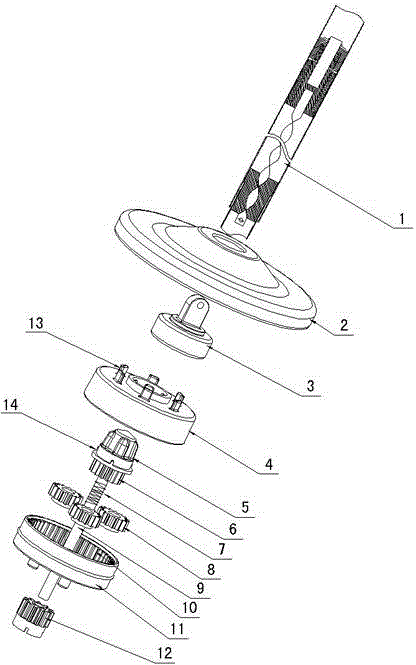

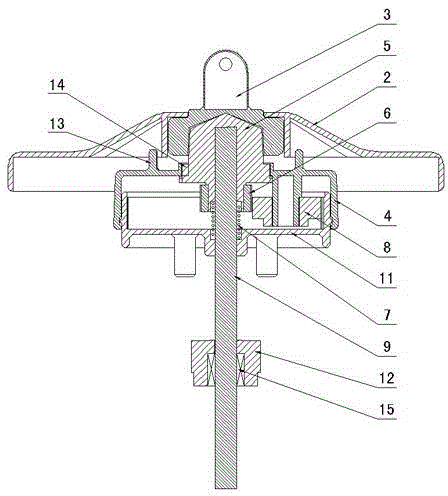

[0017] figure 1 and figure 2 Shown, for the present invention creates the specific embodiment of a kind of rotating mop transmission device, it comprises planetary gear housing 4, cleaning joint 5, driving gear 6, planetary gear set 8, power transmission shaft 9, fixed seat 11, described The fixed seat 11 is fixed on the cleaning bucket, the transmission shaft 9 is fixedly connected with the cleaning connector 5 and is rotatably arranged on the fixed seat 11, and the planetary wheel housing 4 is rotatably covered on the fixed seat 11 to form a closed space. The driving gear 6 and the planetary gear set 8 are installed in the closed space, and the cleaning connector 5 is provided with a transmission disc 14 meshing with the center hole of the planetary gear housing 4, and the head of the cleaning connector 5 protrudes from the planetary gear housing 4. The driving gear 6 is set on the cleaning connector 5 or the transmission shaft 9, the planetary gear set 8 is rotatably set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com