A rice grading machine with high screening efficiency

A technology of screening efficiency and classifier, which is used in sieves, solid separation, and separation of solids from solids by air flow. The effect of dispersing effect, enhancing screening efficiency and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

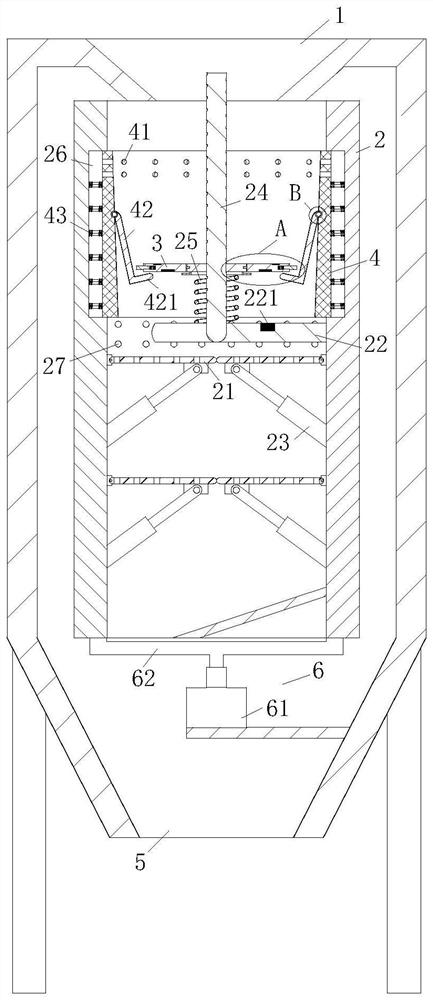

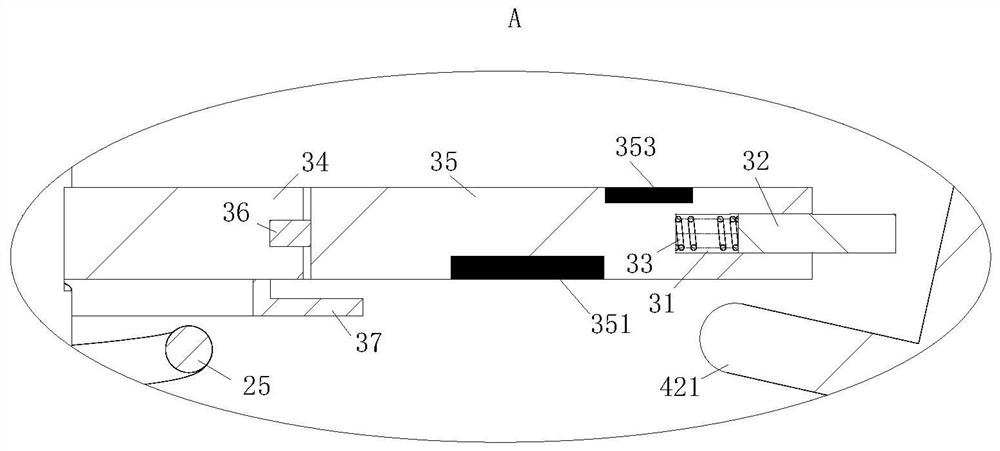

[0031] As an embodiment of the present invention, a No. 1 annular groove 31 is provided on the side wall of the rotating plate 3; an arc-shaped plate 32 is slidably connected in the No. 1 annular groove 31; the number of the arc-shaped plates 32 is at least two , No. 2 spring 33 is arranged between the arc-shaped plate 32 and the groove bottom of No. 1 annular groove 31; Fixed connection; during work, the rotating plate 3 is rotated downward by the gravity of the rice, so that the arc plate 32 stretches the second spring 33 under the action of centrifugal force, so that the arc plate 32 stretches out to the No. 1 annular groove 31, thereby making The gap between the rotating plate 3 and the baffle plate 4 changes, so that the rebound angle of the rice hitting the baffle plate 4 changes, so that the rice is distributed more evenly on the sieve plate 21, thereby improving the screening rate of rice.

[0032] As an embodiment of the present invention, the rotating plate 3 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com