Layering reaction cup plate shelf

A reaction cup and rack technology, applied in the field of layered reaction cup racks, can solve the problems of increasing the width of the reaction cup conveyor belt, increasing the area of equipment workstations, and increasing material consumption, so as to save materials and prolong continuous work Time, easy to grab and use the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

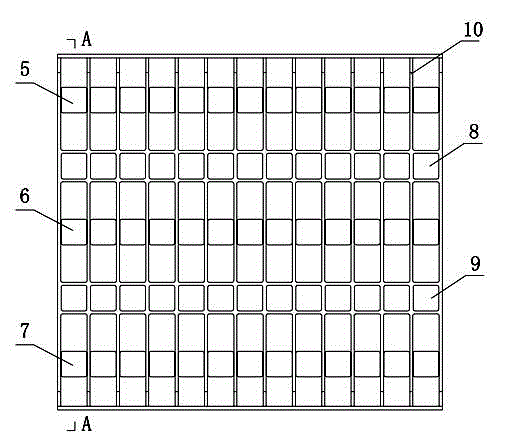

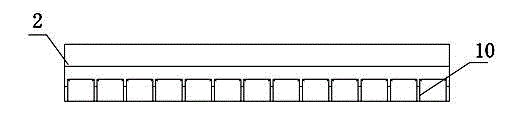

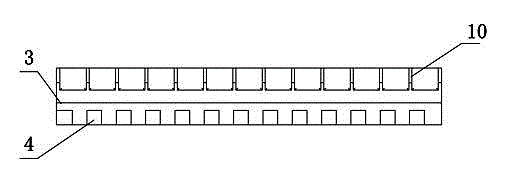

[0015] Such as Figure 1-6 As shown, the layered cuvette plate rack of the present invention includes a plate body 1, vertical plates 2 and 3 arranged at the upper and lower lateral edges of the plate body 1, and are spaced on the plate body 1 from top to bottom. The five rows of cuvette jacks on the top; the height of the upper openings of the cuvette jacks 5, 6, and 7 in the first, third, and fifth rows is lower than the upper openings of the cuvette jacks 8, 9 in the second and fourth rows Height; the vertical plate 3 at the lower horizontal edge is a zigzag 4 structure, which is used for signal detection of the position sensor 11 arranged on the analytical instrument; a partition 10 is arranged between the cuvette sockets of adjacent rows , the height of the partition 10 is equal to the height of the upper openings of the cuvette sockets 8 and 9 in the second and fourth rows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com