Manufacturing method and molding apparatus for heating molded decorative board

A manufacturing method and thermoforming technology, applied in chemical instruments and methods, lamination devices, layered products, etc., can solve the problems of peeling damage, cracks on the surface of the connecting surface, and high defect rate in the process, so as to avoid cracks or deformation , the effect of firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now attached in detail with the accompanying drawings as follows. The embodiments illustrated in the accompanying drawings are only used to illustrate the technical solution of the present invention , not to limit the present invention. The same components will be described with the same reference numerals.

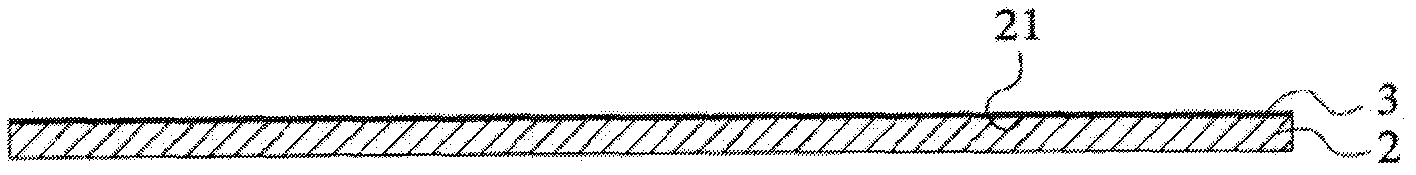

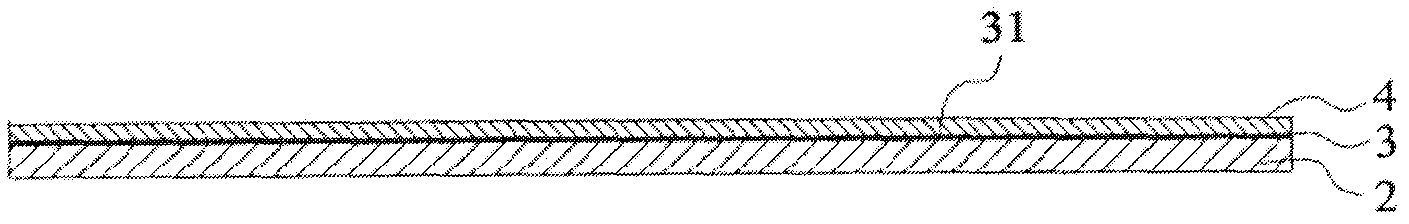

[0024] Please also see Figure 1A ~ Figure 1H , figure 2 and image 3 , Figure 1A ~ Figure 1F It is a cross-sectional view of the process realized by the manufacturing method of the thermoformed decorative panel according to the present invention, figure 2 It is a perspective view of a decorative board combined on a notebook computer according to a preferred embodiment of the present invention, image 3 It is a flowchart of a manufacturing method according to a preferred embodiment of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com