Structure of mounting cowl-top cover

A technology for installing structures and front covers, which is applied to the upper structure, upper structure sub-assembly, sealing device, etc., to achieve the effect of improving the appearance aesthetics and firmly engaging the state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

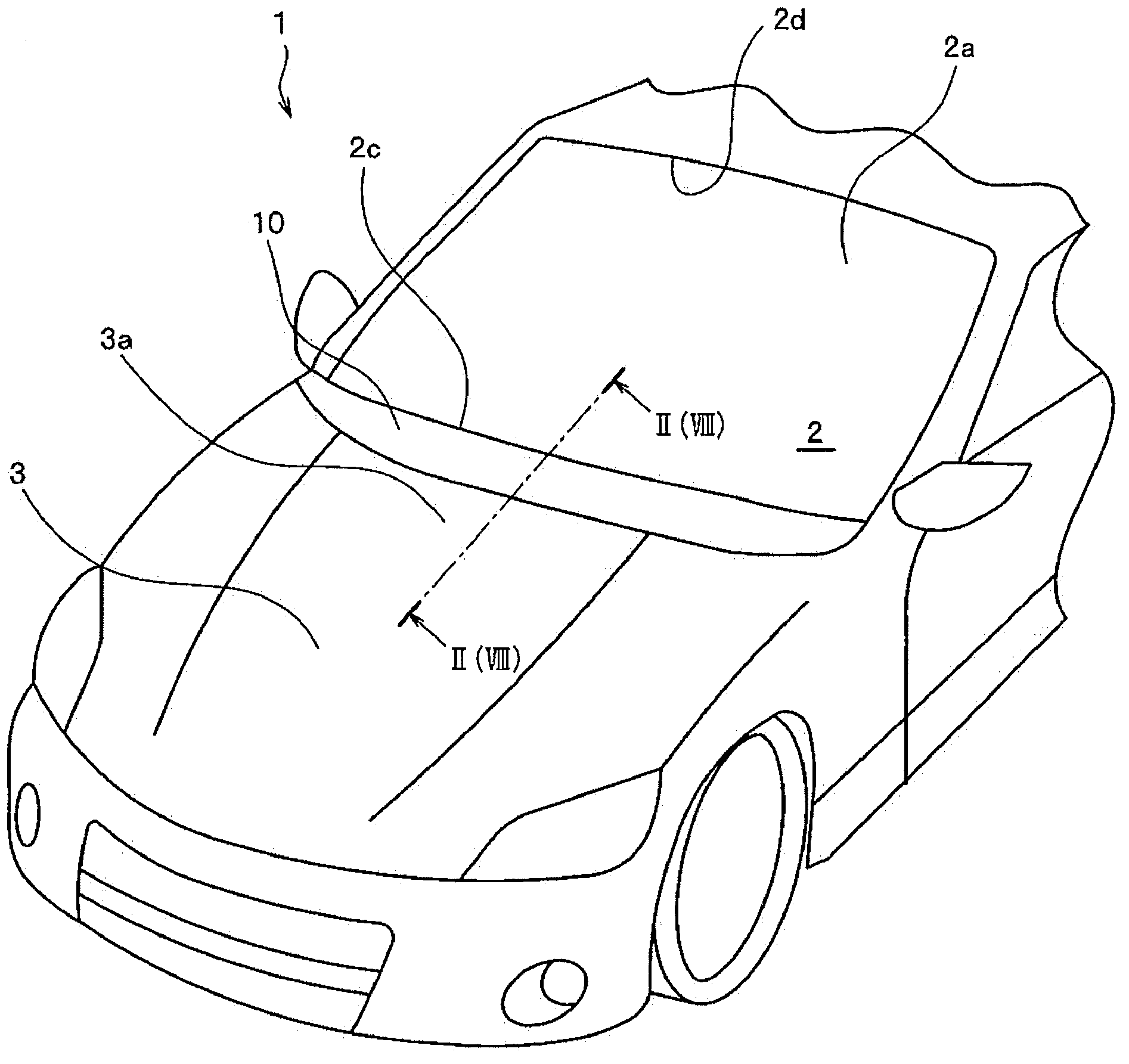

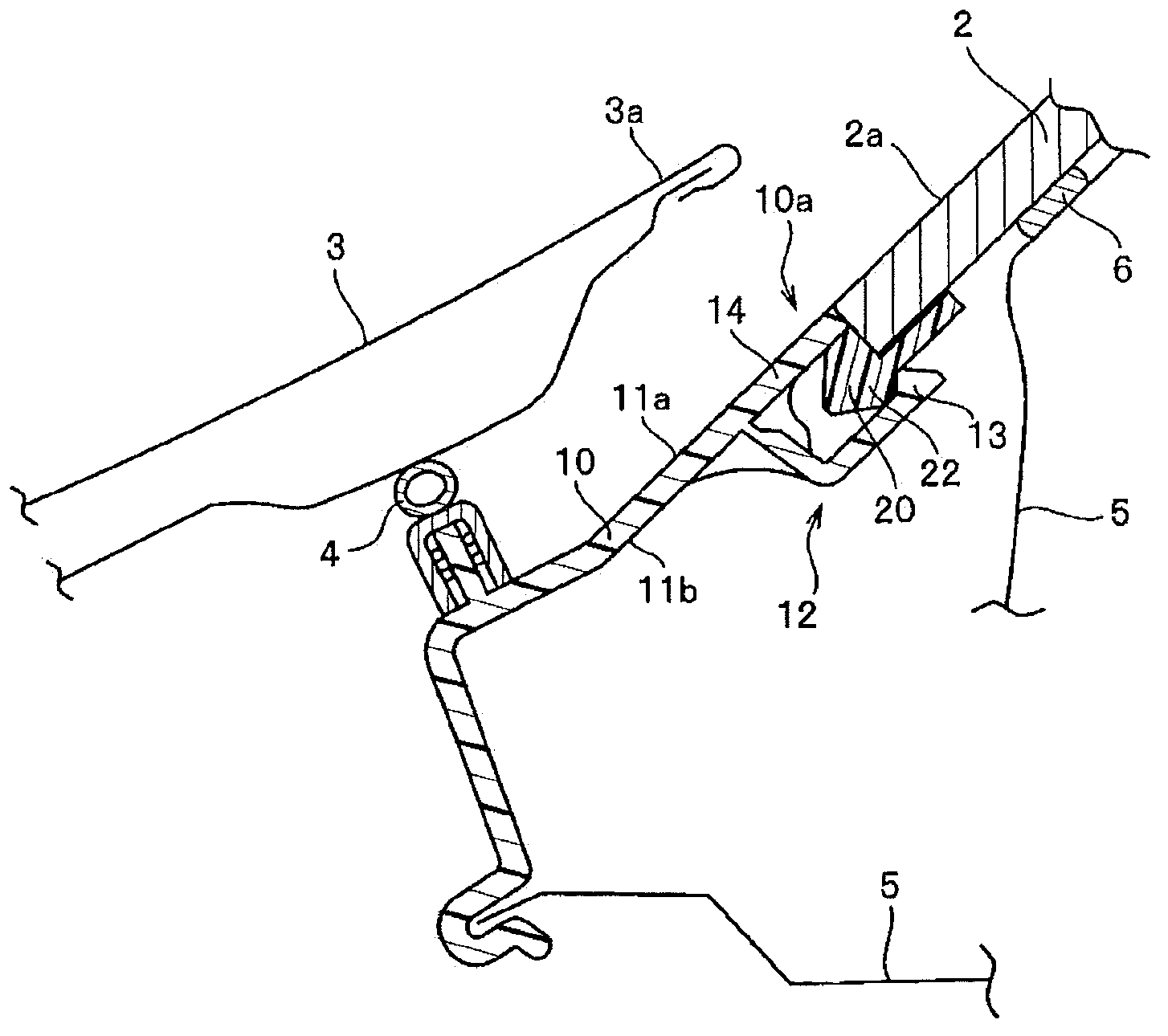

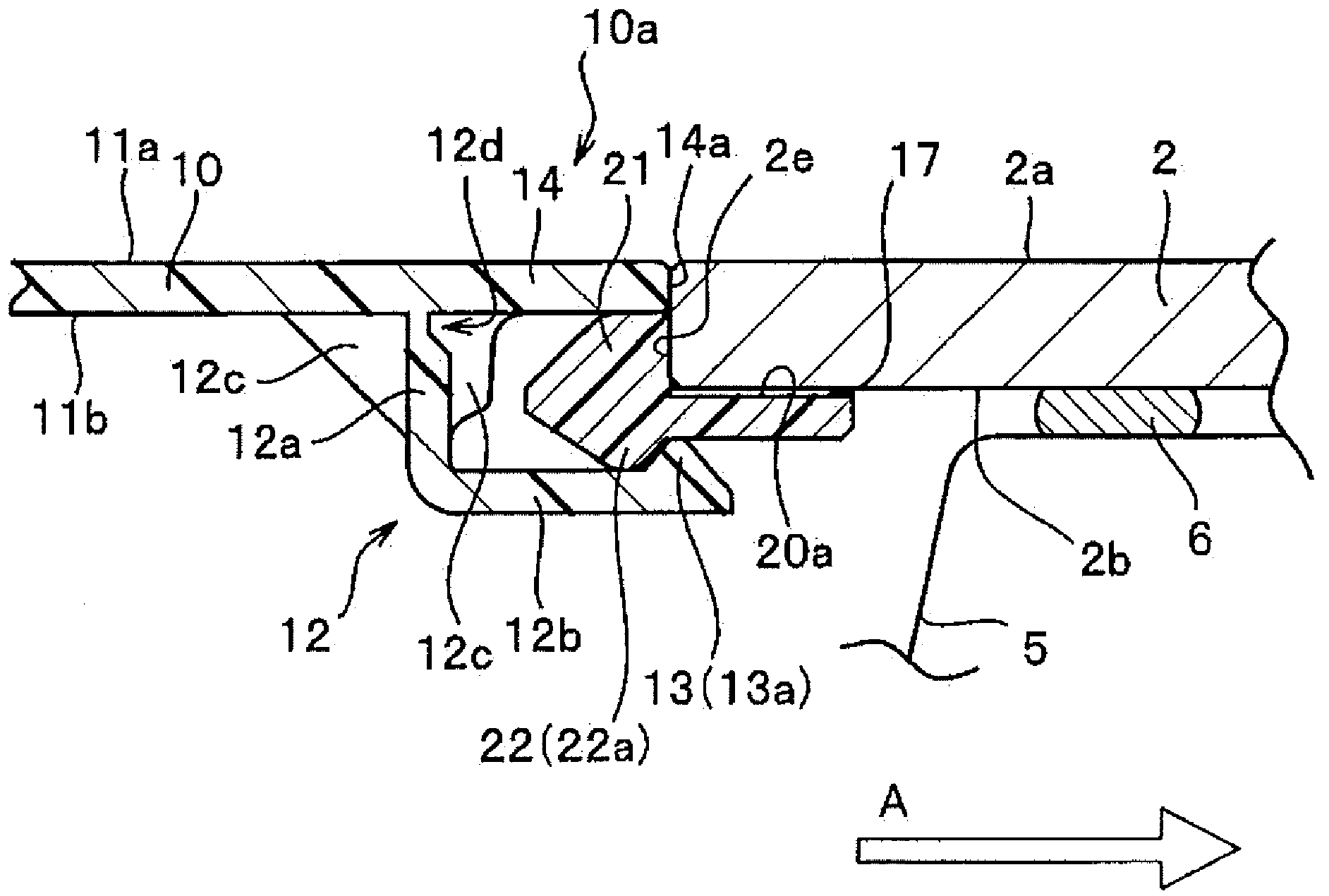

[0084] In the first embodiment, using Figure 2 ~ Figure 4 , a configuration example in which a stepped portion formed on the clamp member is used as an engaged portion to be engaged with the front cover will be described. First, use figure 1 The arrangement structure of the cowl 10 in the vehicle 1 will be described.

[0085] figure 1 It shows a perspective view of the vehicle 1 viewed obliquely from the front. In addition, illustration of wipers and the like is omitted. A windshield 2 is disposed on the front side of the cabin of the vehicle 1, and the windshield 2 is disposed in such a manner that the surface 2a of the windshield 2 faces toward the rear of the vehicle from the lower end 2c of the windshield 2 toward the upper end 2d that is the upper side of the vehicle body. sideways. Furthermore, a cowl panel 10 covers a space between a lower end portion of the windshield glass 2 and a rear end portion 3 a of the engine hood 3 covering the upper opening that partit...

no. 2 Embodiment approach )

[0104] In the second embodiment, like the first embodiment, the engaging portion of the cowl is engaged with the stepped portion formed on the clamp member, but the structure according to the modified example uses Figure 5 ~ Figure 7 Describe it. exist Figure 5 In the illustrated configuration example, the engaged portion 22 of the clamp member 20 is formed as a stepped portion 22b protruding upward, and the engaging portion 13 of the cowl 10 that engages with the stepped portion 22b is formed on the front cover 10. The rear end of the engagement portion 14 is formed in a downward shape. In addition, when the front cover 10 is engaged with the clamp member 20 , the bent piece 12 b of the tongue piece 12 pushes the bottom surface of the front end side of the clamp member 20 upward, and sandwiches the clamp member with the engaging portion 13 . 20. Other configurations have the same configurations as those in the first embodiment, and for the same configurations, descriptio...

no. 3 Embodiment approach )

[0118] In the third embodiment, the engaging portion formed on the front cover is clamped by the engaged portion formed on the clamp member, and the Figure 8 ~ Figure 10 This configuration example will be described. In the third embodiment, the engaging portion formed on the front cover is clamped by the engaged portion formed on the clamping member, and the clamping member is provided in order to obtain a clamping force. The structure of the core material for reinforcement. Furthermore, the structure of the engaging portion on the cowl is sandwiched by the engaged portion, and the structure differs from the structure in the first embodiment in these respects. Other configurations have the same configurations as those in the first embodiment, and for the same configurations, descriptions of the components are omitted by using the component symbols used in the first embodiment.

[0119] as figure 1 of the VIII-VIII section Figure 8 and as Figure 8 Enlarged view of main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com