Plastic flat (round) filament winding device

A technology of winding device and plastic, which is applied in thin material processing, transportation and packaging, and transportation of filamentous materials, etc., can solve the problems of high manufacturing and maintenance costs, high power consumption, and difficulty in weaving, and achieves reduction of power consumption and savings. Effects of Manufacturing and Repair Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments are further described in detail below in conjunction with accompanying drawings

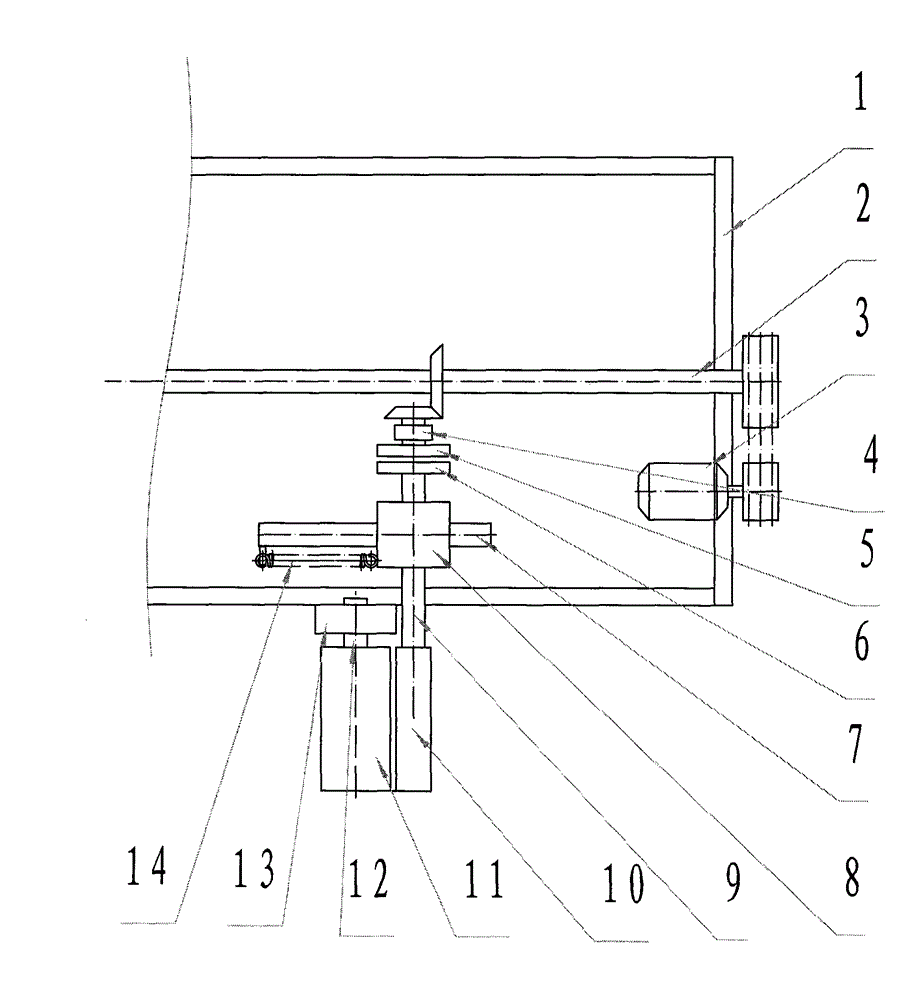

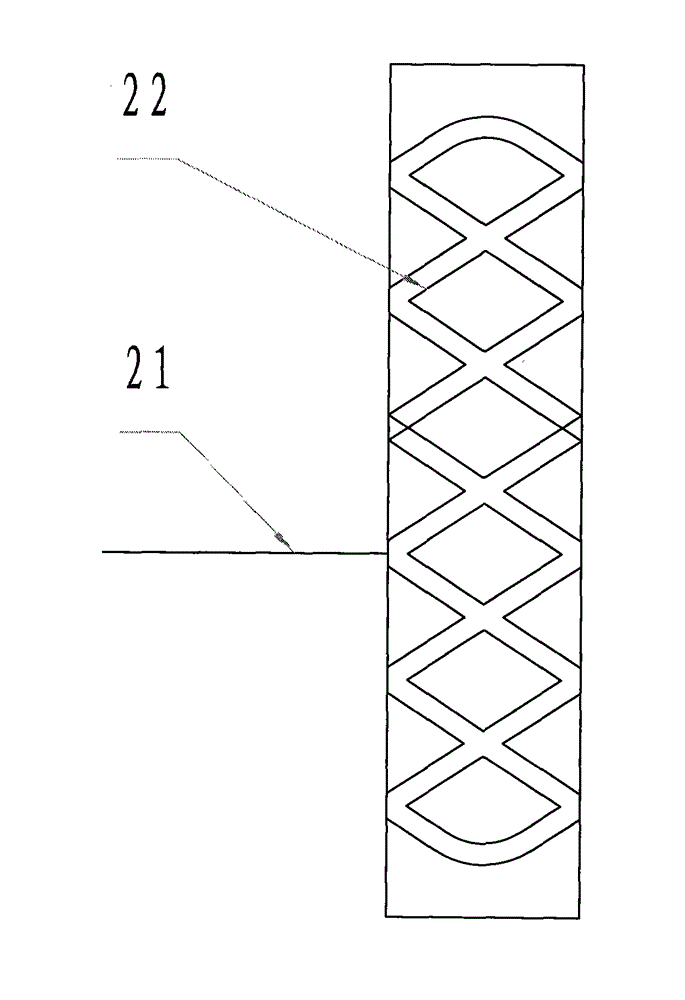

[0010] refer to figure 1 : figure 1 It is a structural schematic diagram of an embodiment of the device of the present invention, combined with figure 2 , 1-base frame, 2-main drive shaft, 3-motor, 4-magnetic main drive plate seat, 5-magnetic main drive plate, 6-magnetic driven plate, 7-linear guide rail, 8-bobbin shaft seat, 9-bobbin shaft, 10-bobbin tube, 11-groove barrel, 12-groove barrel shaft, 13-groove barrel shaft seat, 14-spring, 21-plastic wire, 22-curve groove, motor 3, main drive shaft 2. The magnetic main transmission disk seat 4, the groove cylinder shaft seat 13 and the linear guide rail 7 are fastened and installed on the bracket 1 respectively, and the magnetic main transmission disk 5 is installed in the magnetic main transmission disk seat 4, and the magnetic main transmission disk 5 is connected with the main magnetic transmission disk. The drive shaft 2 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap