Cloth guide roller used for weaving machine

A cloth guide roller and loom technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of poor cloth guide effect and small friction of smooth cloth guide rollers, so as to reduce the difference and reduce the production process Difficulty, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

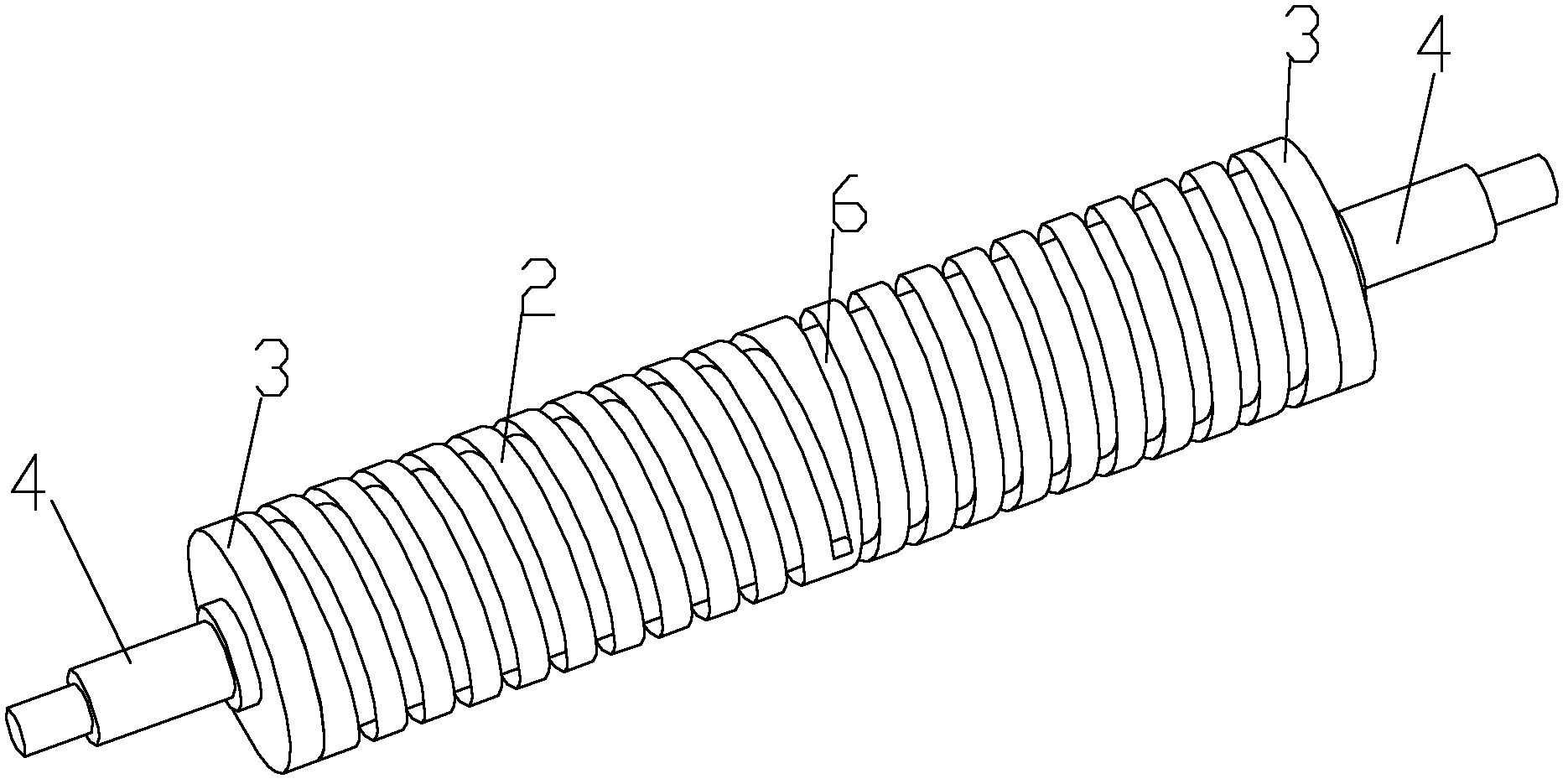

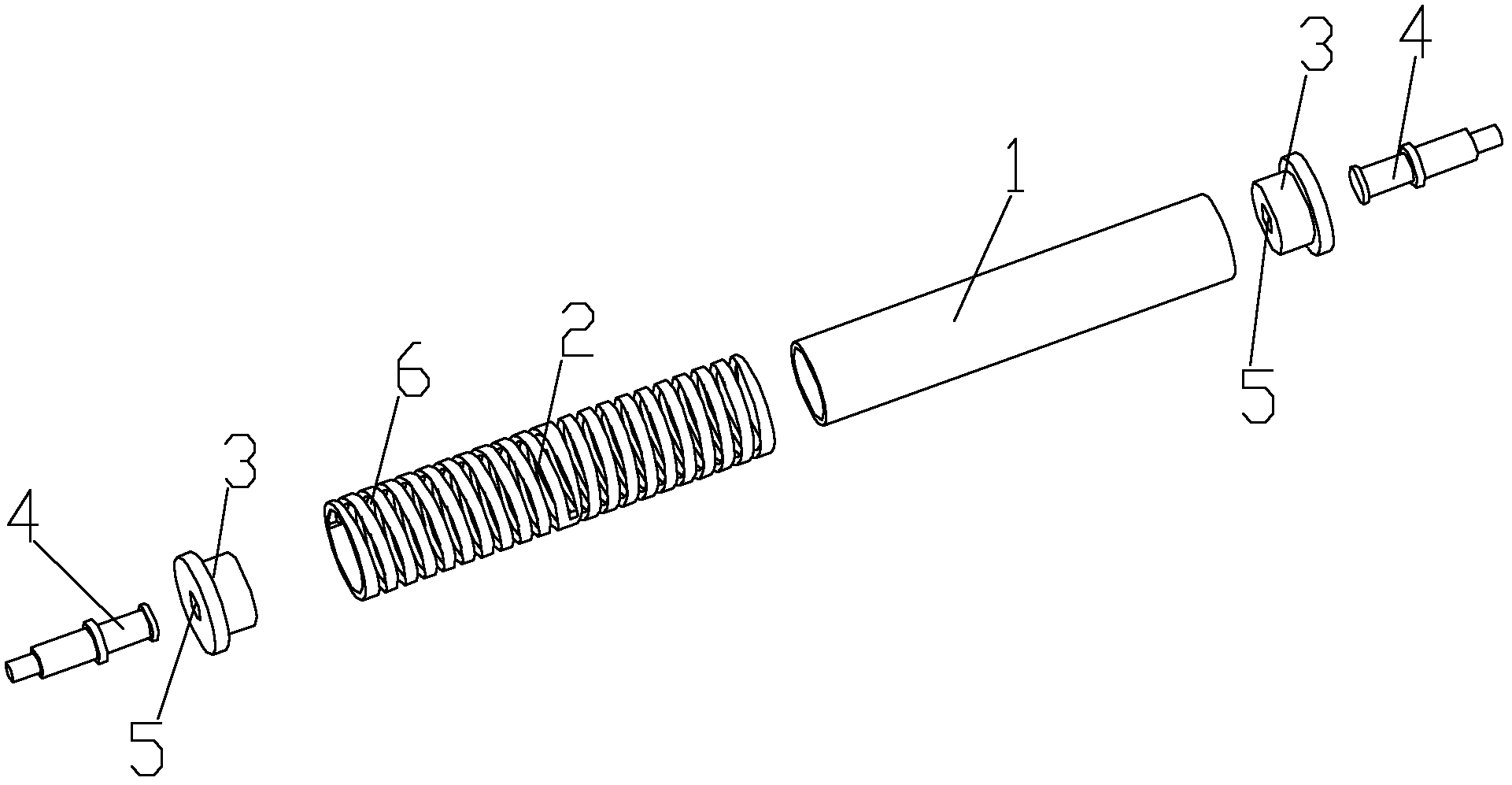

[0014] as attached figure 1 , 2 The cloth guide roller for the loom shown includes a hollow roller 1, a left and right bulkhead plate 3 arranged at both ends of the hollow roller 1, and a bulkhead shaft 4 connected to the center hole 5 of the left and right bulkhead plate, and also includes a socket The hard rubber tube 2 on the hollow roller 1 has spiral grooves 6 with opposite rotation directions on the peripheral surface of the hard rubber tube 2 . The depth of the helical groove 6 is equal to the thickness of the hard rubber tube 2 . The width of the helical groove 6 is less than or equal to its pitch.

[0015] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0016] The cloth guide roller for the loom of the present invention, when the cloth guide roller is in contact with the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com