Spherical multidirectional force measuring support

A force measurement, spherical technology, applied in the direction of measuring force components, bridge parts, bridges, etc., can solve the problems of difficult to estimate differences, hidden safety hazards of structures, complicated internal force calculation, etc., to simplify the structure and realize remote monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

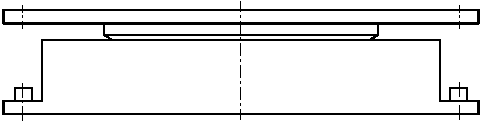

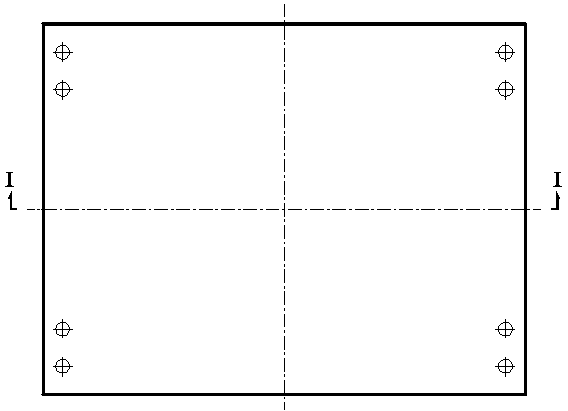

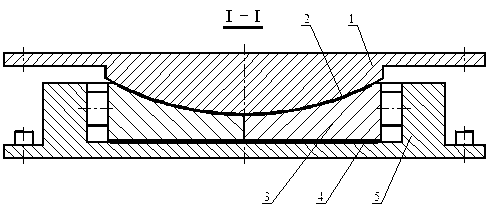

[0025] Combine below Figure 1 to Figure 6 , the present invention is further described:

[0026] as attached Figure 1-4 As shown, the spherical multi-directional force-measuring bearing described in the present invention includes an upper bearing plate 1, a first friction-reducing layer 2, a combined hem 3, a second friction-reducing layer 4, a base 5, a pressure sensor 6, a connection Wire 7 and data acquisition module 8. The top surface of the combined hem 3 is in spherical contact with the bottom surface of the upper support plate 1, the combined hem 3 is located between the upper support plate 1 and the base 5 in the vertical direction, and a plurality of pressure sensors 6 are located between the combined hem 3 and the base in the horizontal direction Between the vertical walls of 5; the electrical signals generated by multiple pressure sensors 6 subjected to the pressure are collected, analyzed and synthesized by the data acquisition module 8 through the connecting w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com