Brake pad production system

A production system and a technology for brake pads, applied in the field of brake pad processing, can solve the problems of insufficient uniformity of brake pad products, unfavorable brake pad production and development, and lack of production systems, so as to promote production and development and the advancement of the market. It is beneficial to the effect of large-scale mechanized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

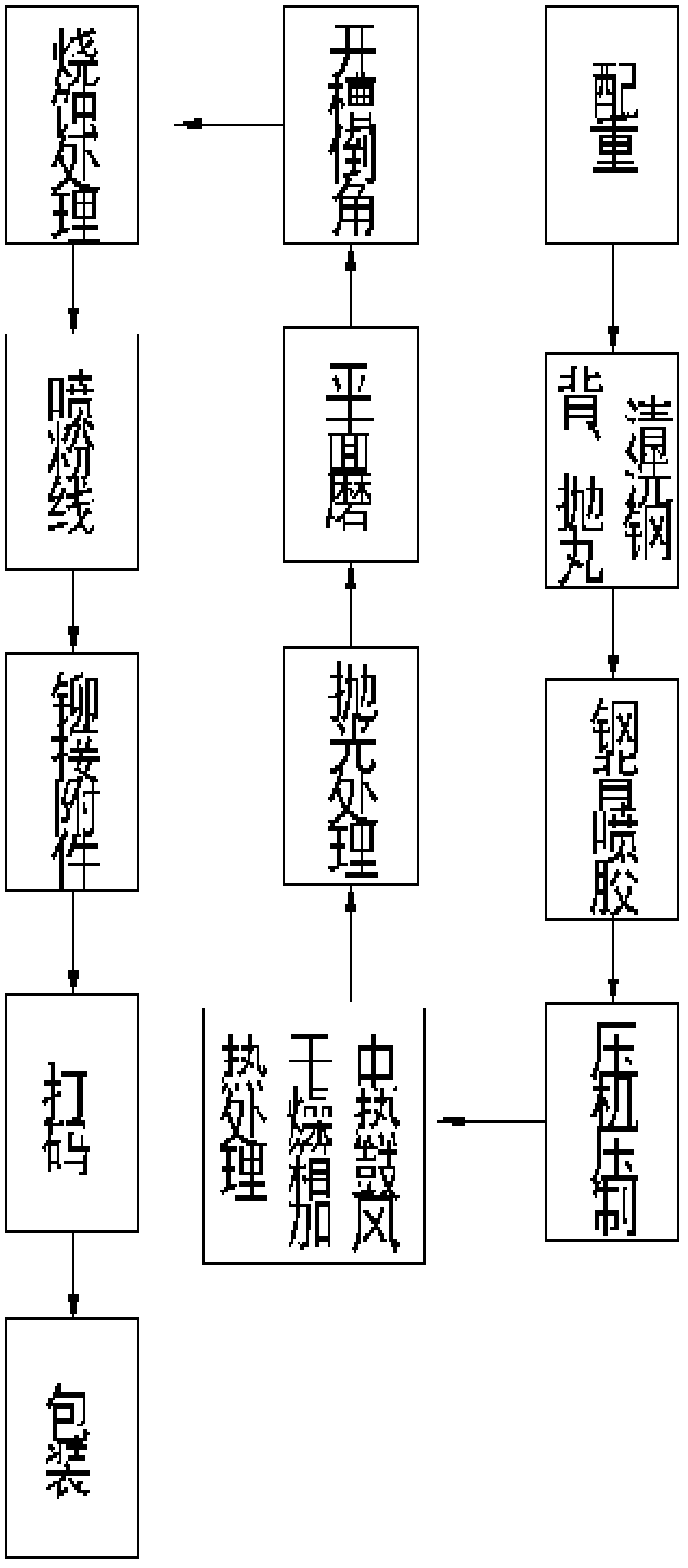

[0012] Such as figure 1 As shown in the production system of brake pads, the friction material is weighed in proportion, the steel back is cleaned, shot blasted, and glue is sprayed on the steel back for about 0.3-0.5 mm, and then the friction material and the steel back are pressed by a press and used The electric blast drying oven is used for heating treatment, polishing treatment, surface grinding, and then slotting and chamfering according to needs, ablation treatment and powder spraying of the entire brake pad, and then riveting accessories on the brake pad, coding and packaging. The temperature of heat treatment is controlled at 150°-300°.

[0013] The basic principles and main features of the present invention and the advantages of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com