High-intensity industrial cutter for steel rolling

A high-strength, industrial technology, used in the field of cutting tools, can solve the problems of poor bending strength and thermal shock resistance, insufficient fracture toughness, easy to produce cracks, etc., and achieve high production efficiency, good wear resistance, and low friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

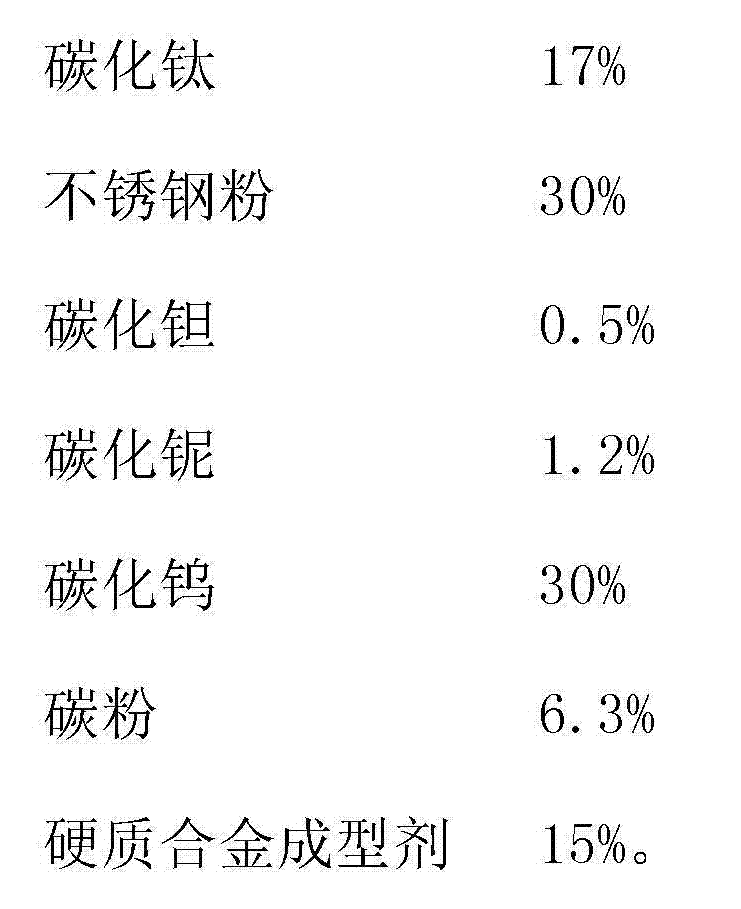

Embodiment 1

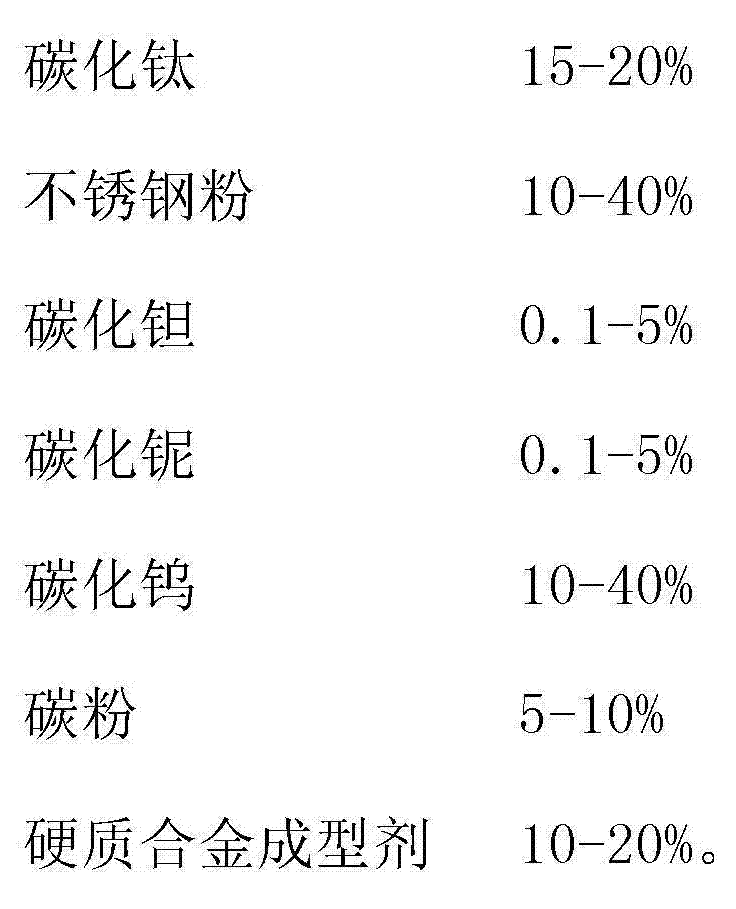

[0023] A high-strength industrial cutting tool for rolling steel, consisting of the following components by weight percentage,

[0024]

[0025] The stainless steel powder is made of 06Cr19Ni10 steel, that is, 304 stainless steel powder.

[0026] The cemented carbide forming agent adopts the cemented carbide forming agent SDB.

[0027] A preparation process for high-strength industrial cutting tools for rolling steel:

[0028] 1) Weigh the raw materials according to the weight ratio of each raw material in the component, and mix the raw materials evenly to make a billet for use;

[0029] 2) Add alcohol to the billet, add the billet and alcohol at a ratio of 1:2, grind in a grinder for 5 hours, and mix the billet and alcohol thoroughly to make a mixture;

[0030] 3) Put the mixed material into the container for precipitation for 2 hours, and remove the clarified alcohol above;

[0031] 4) Put the mixture in step 3) into a drying cabinet to dry, and volatilize the remainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com