Indoor light emitting diode (LED) lighting device with high light evenness degree

A technology of LED lighting and light uniformity, applied in lighting devices, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve problems such as short start-up time, limited heat dissipation performance, inconvenient fan replacement and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings.

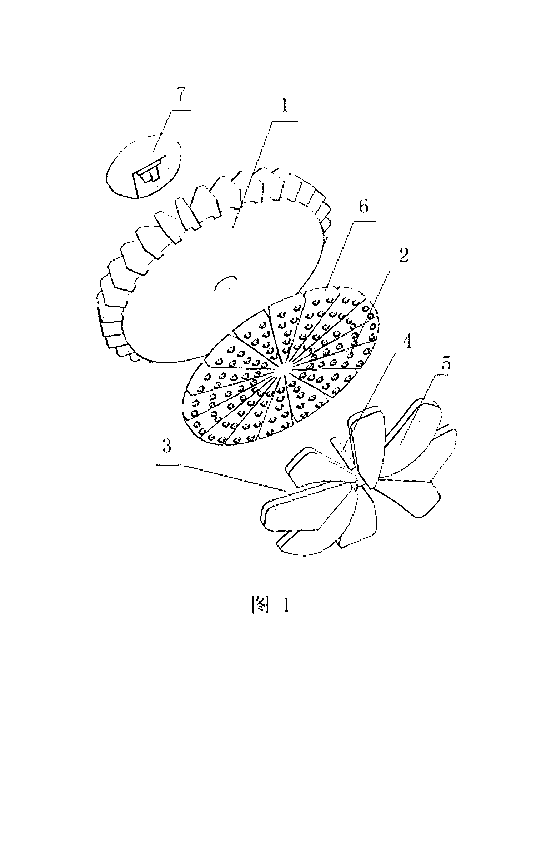

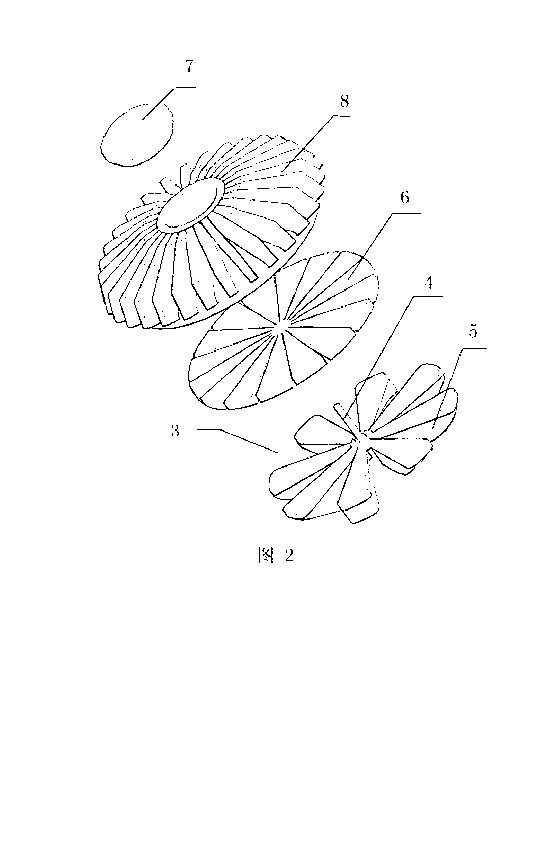

[0019] Such as figure 1 with figure 2 As shown, the LED lighting device includes: a lamp body 1, an LED lamp bead 2, a driver 7 including a driving power supply and a drive system, a rotating light distribution part 3, and are assembled together with the lamp body 1 as a base frame. 1 is a metal structural member with a rotationally symmetrical structure, and its back is provided with heat dissipation fins 8. The LED lamp bead 2 is welded on the aluminum substrate 6, and fixed on the lower end surface of the lamp body 1 through the aluminum substrate, and the light distribution is rotated. Part 3 is in the form of blades, consisting of four sets of symmetrically set blades with different lens structures. Eight discrete blades are evenly spaced and connected into one body through the rotating shaft 4. The rotating light distribution part 3 is located at the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com