Wear-resistant device of water cooling pipe wall of circulation fluidized bed boiler

A technology of circulating fluidized bed and water-cooled tubes, which is applied in the field of anti-wear devices for water-cooled tube walls of circulating fluidized-bed boilers, and can solve problems affecting heat transfer of water-cooled tube walls, bursting of water-cooled wall tubes, and reducing boiler thermal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

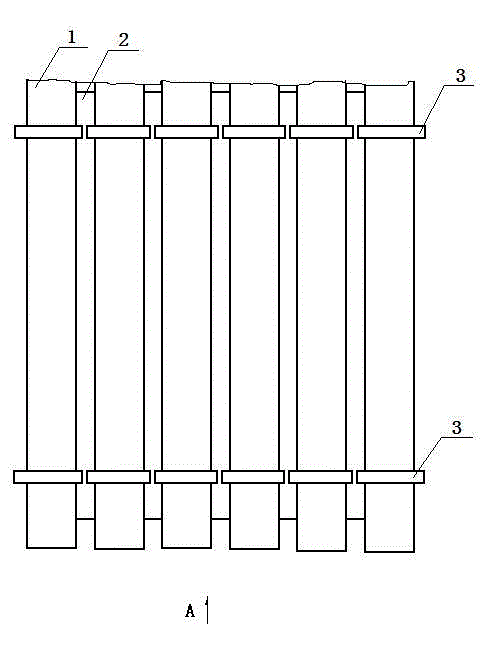

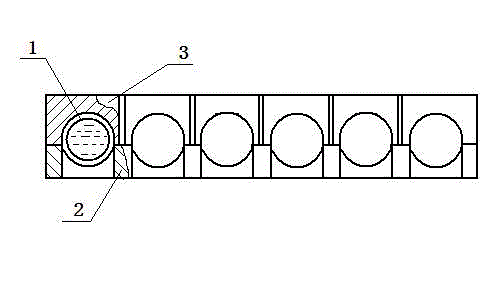

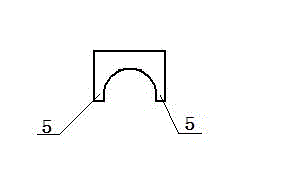

[0016] Such as figure 1 , figure 2 , image 3 As shown, the furnace cooling tubes 1 of the circulating fluidized bed boiler are arranged in rows, and the wall of the water cooling tube 1 facing the fuel forms a plane. The baffles 3 of the water-cooled tube 1 are located on the same plane and form a row, wherein there is a gap between any two adjacent baffles 3, in order to prevent the baffles 3 from being extruded and deformed due to thermal expansion and contraction. There is a semicircular groove 4 on the body of the baffle plate 3, the groove 4 matches the shape of the water cooling tube 1, the two sides of the groove 4 of the baffle plate 3 are supporting feet 5, and the supporting feet 5 are welded and connected with the rib plate 2. The groove 4 and the water-cooling tube 1 are also welded and connected, the distance between the axially adjacent two rows of baffles 3 of the water-cooling tube 1 is 1.3 meters, and the distance from the highest point of the groove 4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com