Rotary circling mechanism

A ring-wrapping and rotating head technology, applied in the field of optical fiber rings, can solve the problems of fiber rings that cannot be separated from manual operation, irregular arrangement of optical fiber rings, and insufficient functions, so as to prevent fiber breakage, ensure consistency, and realize automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

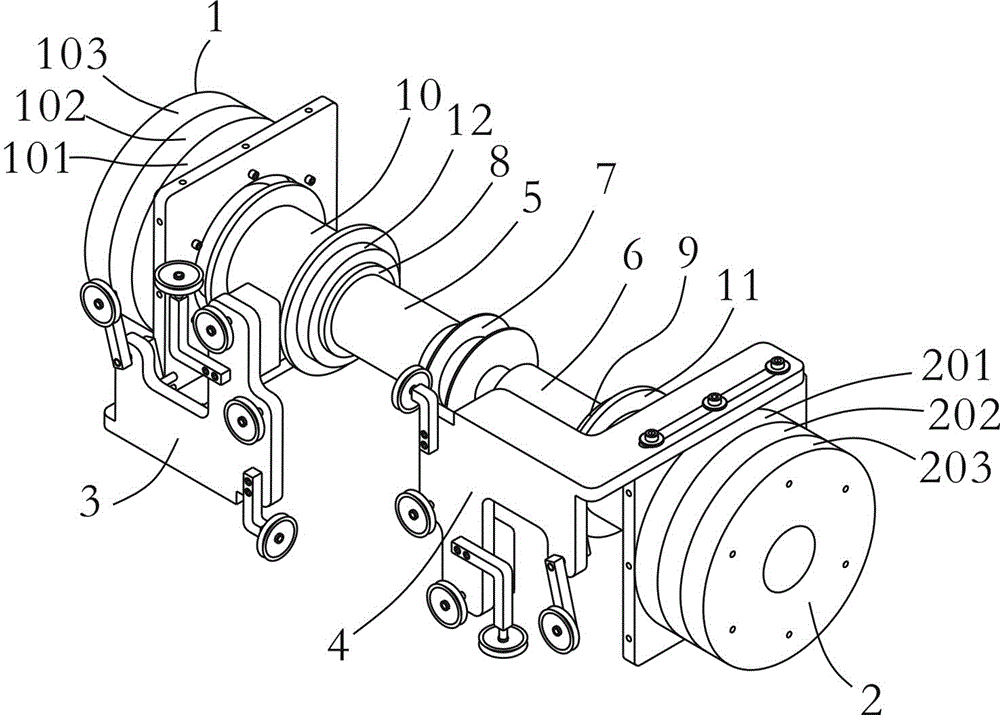

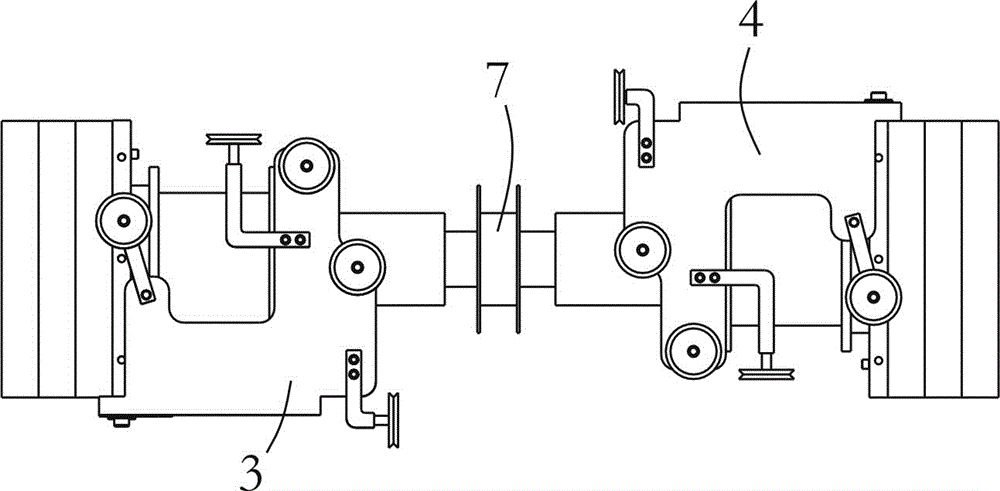

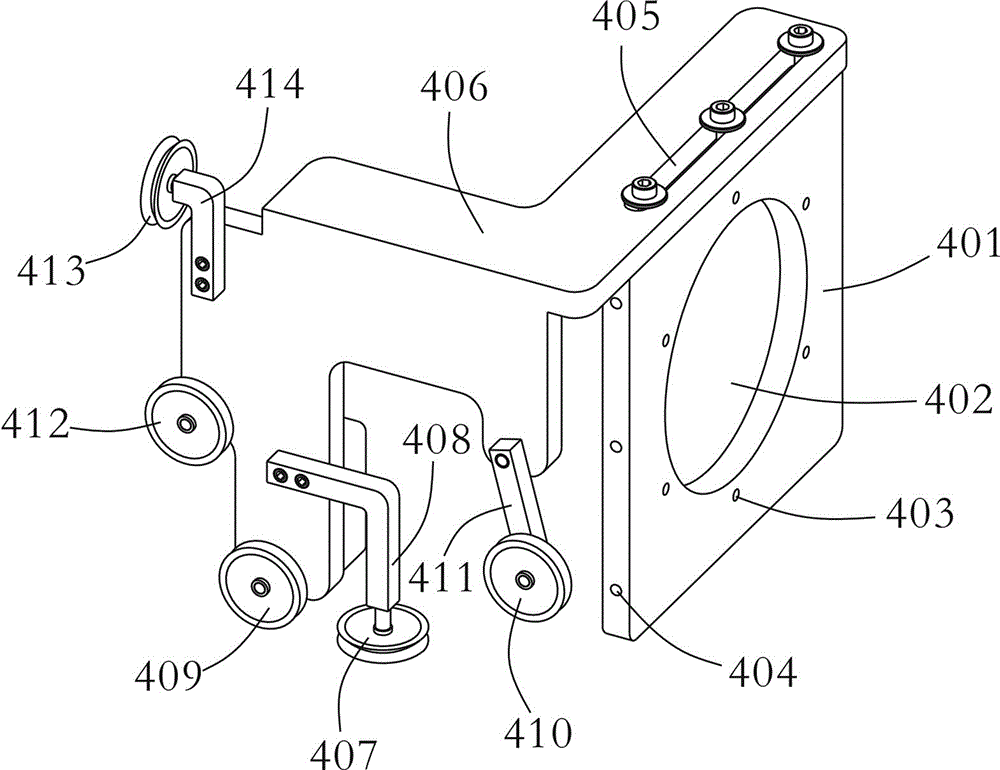

[0029] like Figure 1 to Figure 4 As shown, a rotating loop mechanism of the present invention includes a pair of loop arms with the same structure, which are called a left loop arm and a right loop arm. Taking the right winding arm as an example, it includes a right guide wheel frame 4 and a right rotating head 2 , a right main shaft 6 , a right fiber feeding shaft 9 and a right fiber tray 11 arranged coaxially. The right rotary head 2 is a gear set composed of a right idler gear 201 , a right fiber feeding shaft gear 202 and a right shaft gear 203 . The right idler gear 201 , the right unwinding shaft gear 202 and the right shaft gear 203 are coaxially arranged and do not interfere with each other, and can rotate in forward / reverse directions respectively driven by external power equipment such as motors. The right winding arm ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com