A kind of graphene transfer annealing method and manufactured device based on Aln substrate

A graphene, single-layer graphene technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as less experimental analysis, and achieve the advantages of suppressing doping effect, reducing residual amount, and optimizing annealing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

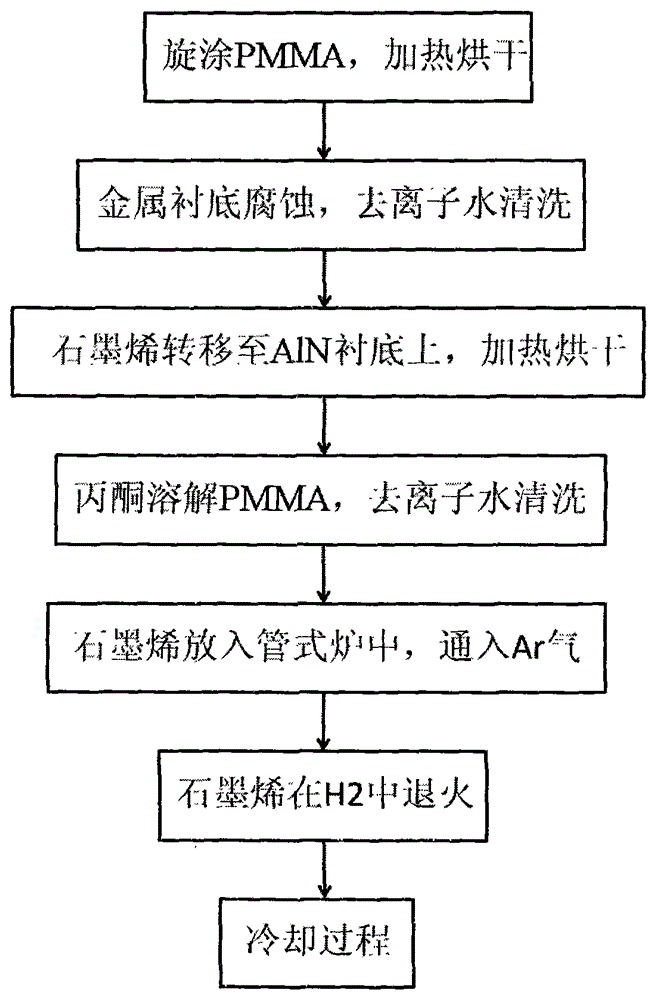

[0024] Fact steps of the present invention are as follows:

[0025] Step 1 Spin-coat a layer of PMMA on the graphene surface, heat the temperature to 60°C, and dry for 5 minutes;

[0026] Step 2 put the graphene into the ferric nitrate aqueous solution with a mass fraction of 10%, with the metal substrate layer facing down and the PMMA layer facing up until the metal layer is completely corroded, then cleaning with deionized water to remove the residual corrosion solution ;

[0027] Step 3 transfers the graphene / PMMA layer obtained in step (2) to an AlN substrate, and then bakes it for 20 minutes at a temperature of 60° C.;

[0028] Step 4 puts the PMMA / graphene / AlN substrate obtained in step (3) into an acetone solution to dissolve the PMMA, and then cleans it with deionized water;

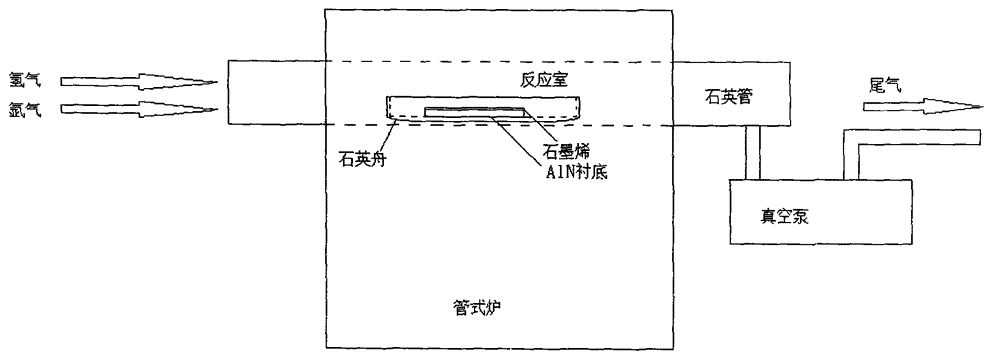

[0029] Step 5 Put the graphene transferred onto the AlN substrate into a tube furnace, vacuumize the tube furnace to 0.1Pa, and feed high-purity (purity > 99.9%) Ar gas into the tube furnace wi...

Embodiment 2

[0034] Fact steps of the present invention are as follows:

[0035] Step A Spin-coat a layer of PMMA on the graphene surface, heat the temperature to 50°C, and dry for 5 minutes;

[0036] Step B puts the graphene into the ferric nitrate aqueous solution with a mass fraction of 5%, with the metal substrate layer facing down and the PMMA layer facing up until the metal layer is completely corroded, then cleaning with deionized water to remove the residual corrosion solution ;

[0037] In step C, the graphene / PMMA layer obtained in step (2) is transferred to an AlN substrate, and then dried at 80° C. for 20 minutes;

[0038] Step D puts the PMMA / graphene / AlN substrate obtained in step (3) into an acetone solution to dissolve the PMMA, and then cleans it with deionized water;

[0039] Step E puts the graphene transferred onto the AlN substrate into a tube furnace, evacuates the tube furnace to 1Pa, and feeds high-purity (purity>99.9%) Ar gas into the tube furnace with a flow rat...

Embodiment 3

[0044] Fact steps of the present invention are as follows:

[0045] Step 1 Spin-coat a layer of PMMA on the graphene surface, heat to 80°C, and dry for 5 minutes;

[0046] Step 2 Put the graphene into a 20% ferric nitrate aqueous solution with the metal substrate layer facing down and the PMMA layer facing up until the metal layer is completely corroded, then clean it with deionized water to remove the residual corrosion solution ;

[0047] In step 3, the graphene / PMMA layer obtained in step (2) is transferred to an AlN substrate, and then dried at 60° C. for 40 minutes;

[0048] Step 4 puts the PMMA / graphene / AlN substrate obtained in step (3) into an acetone solution to dissolve the PMMA, and then cleans it with deionized water;

[0049] Step 5 Put the graphene transferred onto the AlN substrate into a tube furnace, vacuumize the tube furnace to 0.5 Pa, and feed high-purity (purity > 99.9%) Ar gas into the tube furnace with a flow rate of 150 sccm for 15 minutes , in order t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com