Connecting column with elastic metal sleeves

A technology of elastic metal and metal sleeves, applied in the direction of connection, fixed connection, conductive connection, etc., can solve the problems of interfering magnetic field, low production efficiency, low conductive reliability, etc., and achieve the effect of reducing welding and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

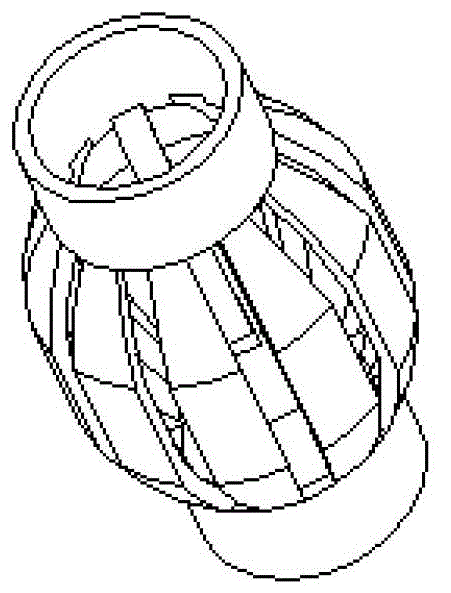

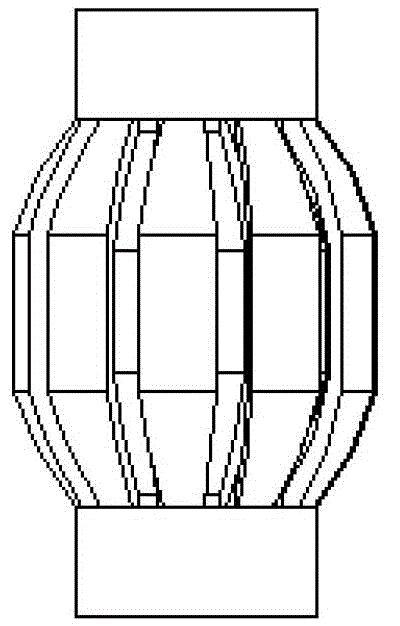

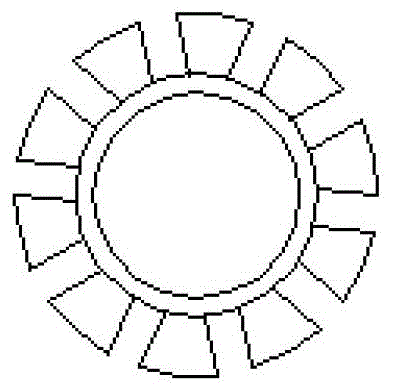

[0014] Referring to the attached picture:

[0015] The connection column 1 with an elastic metal sleeve according to the present invention is characterized in that it includes a cylindrical conductive shaft 11, and an elastic metal sleeve 12 is covered on the shaft 11, and the outer middle part of the metal sleeve 12 is The drum and the end are sleeved on the shaft 11; at least one of the metal sleeves 12 is matched with the conductive round hole of the circuit board, and at least one of the metal sleeves is matched with the conductive round hole of the wire terminal. The outer diameter of the middle part of the metal sleeve 12 is smaller than the inner diameter of the circular hole.

[0016] The end of the metal sleeve 12 is connected to the shaft shoulder 13 of the shaft.

[0017] After one end of the present invention is pressed into the terminal 31 of the terminal button 3 of the ammeter, the circuit board 2 is pressed into the other end of the terminal, and the conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com