High-capacity size mixer

A paste mixing machine and large-capacity technology, applied in mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve problems such as poor mixing effect, uneven slurry, potential safety hazards, etc., and achieve simplified slurry mixing The effects of operation, quality improvement, and pulping work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

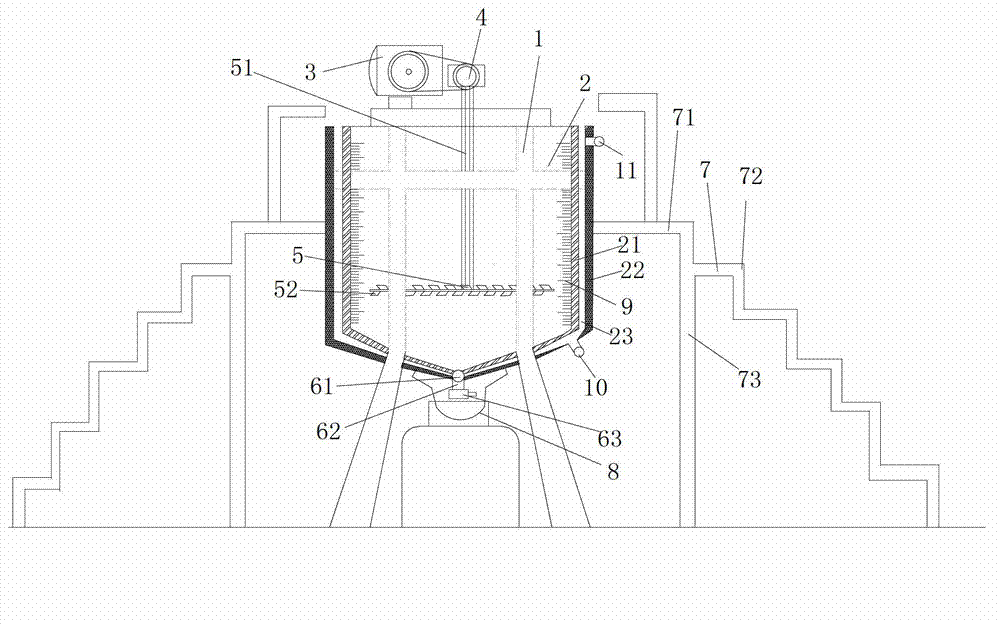

[0015] refer to figure 1 , a large-capacity pulping machine of the present invention, including a frame 1, a slurry tank 2, two operating platform mechanisms 7, a water inlet 10, a water outlet 11, a motor 3, a speed controller 4, a stirring mechanism 5, and a discharge Mechanism 6, filter sieve 8 and scale 9, the slurry bucket 2 is fixedly installed on the frame 1, and both sides of the slurry bucket 2 are equipped with an operation platform mechanism 7, and the operation platform mechanism 7 includes a standing Platform 71, step structure 72 and four support rods 73, described stand platform 71 is welded with the upper end of frame 1, and described stand platform 71 is positioned at the upper end of step structure 72, and described support rod 73 and step structure 72 cooperate to install , and support the step structure 72, the slurry tank 2 is composed of an upper half and a lower half, the upper half is a cylindrical structure, and the lower half is an inverted cone struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com