Preparation method of magnetic cobalt nanometer material

A magnetic nanometer and cobalt nanotechnology, which is applied in the field of preparing stable metal cobalt nanomaterials and regulating the morphology of nanomaterials, can solve the problems of reducing the magnetism of cobalt nanomaterials, and achieve the effects of industrial production, convenient raw materials, and less production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Moorbi by cobalt nitrate and 摩 is 1: 6, which are called 1.4545 g of trifle with six crystal water, respectively, and 1.500 g of a crystalline water, which is dissolved in 70 ml of propylene glycol (propylene glycol (propylene trifleholThe amount of dosage is fully dissolved in cobalt nitrate, pyrine, and anion surface active agent).Add the role of 原 to the reducing agent, and at the same time, the N atom can be equipped with CO, which affects the structure and appearance of the product.As a solvents, it uses its high viscosity to affect the movement of ions and control the agglomeration of the product.

[0025] 2. Heat the above solution to boiling and return to 1.5 hours.

[0026] 3. Separate the above solution with a magnetic separation method to obtain magnetic particles.Wash with water -free ethanol and acetone several times to dry.

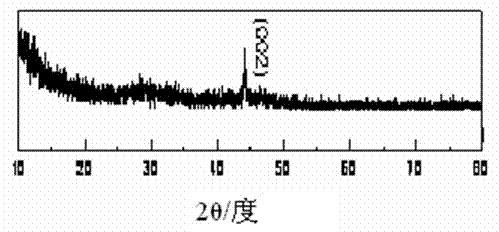

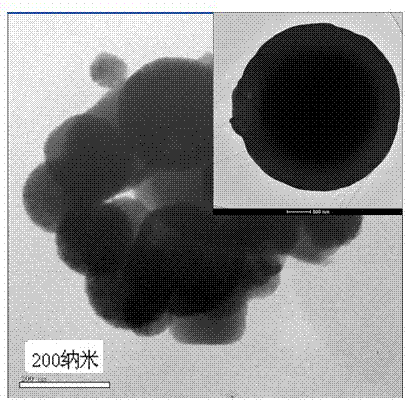

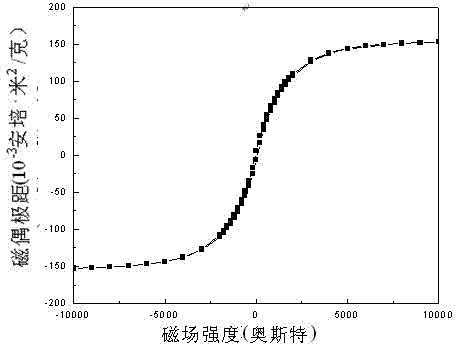

[0027] like figure 1 As well as 2 And 3 shown.The structure and phase identification of the product adopt the Bruker Axs D8 Advance X...

Embodiment 2

[0033] 1. Moorbi by cobalt nitrate and 摩 is 1: 6, respectively, respectively, respectively.Sodium 0.0308 g, dissolved in 70 ml of propylene glycol (the amount of propylene glycol is fully dissolved in cobalt nitrate, pyrine, and anion surface active agent).Add the role of 原 to the reducing agent, and at the same time, the N atom can be equipped with CO, which affects the structure and appearance of the product.As a solvents, it uses its high viscosity to affect the movement of ions and control the agglomeration of the product.(2 -ethyl) sodium amber sodium sodium sulfonate is a double -tailed anion surfactant with strong surface activity.It can be adsorbed to the surface of the solid particles, affecting its growth and gathering.

[0034] 2. Heat the above solution to boiling and return to 1.5 hours.

[0035] 3. Separate the above solution with a magnetic separation method to obtain magnetic particles.Wash with water -free ethanol and acetone several times to dry.

[0036] like Fi...

Embodiment 3

[0042] 1. Moorbi by cobalt nitrate and 摩 is 1: 6, respectively, respectively, respectively.Sodium 0.1540 g, dissolved in 70 ml of propylene glycol (the amount of propylene glycol is fully dissolved in cobalt nitrate, pyrine, and anion surface active agent).Add the role of 原 to the reducing agent, and at the same time, the N atom can be equipped with CO, which affects the structure and appearance of the product.As a solvents, it uses its high viscosity to affect the movement of ions and control the agglomeration of the product.(2 -ethyl) sodium amber sodium sodium sulfonate is a double -tailed anion surfactant with strong surface activity.It can be adsorbed to the surface of the solid particles, affecting its growth and gathering.

[0043] 2. Heat the above solution to boiling and return to 1.5 hours.

[0044] 3. Separate the above solution with a magnetic separation method to obtain magnetic particles.Wash with water -free ethanol and acetone several times to dry.

[0045] like Fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap