Method for processing holes on circumferences of hubs

A processing method and a circle technology, applied in the direction of the drilling mold used for the workpiece, etc., can solve the problems of increasing production costs, increasing the performance requirements of machining equipment, and high position requirements, so as to improve production efficiency, reduce processing costs, and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

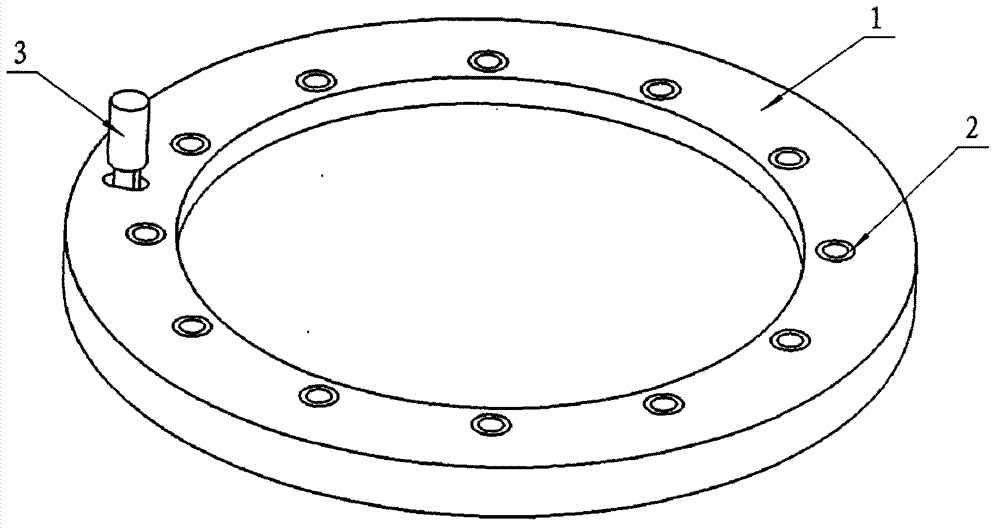

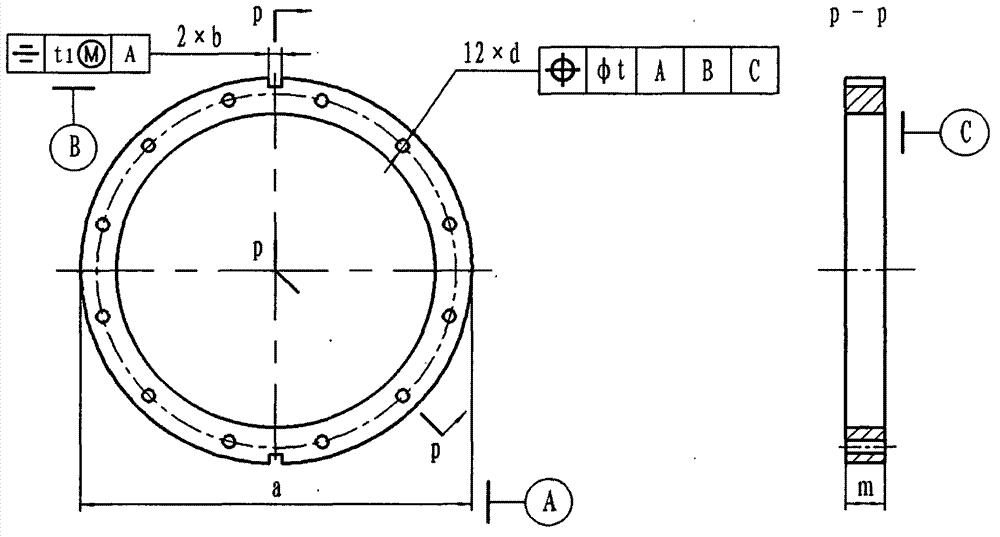

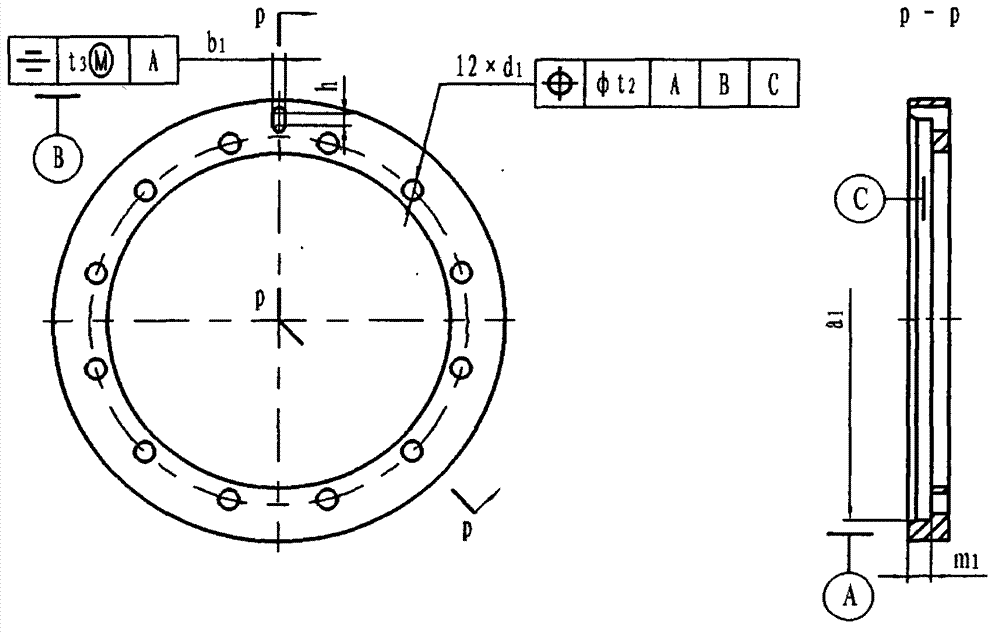

[0026] Embodiments of the present invention: with figure 1 , 2 , 3, 4, 5 as examples for illustration.

[0027] First, analyze the structure and size of the part, the position requirements of the hole and keyway on the circumference of the part and other datums;

[0028] 1. Analyze the size and shape tolerance requirements of the keyway on the part and the hole on the circumference, and the relevant dimensions such as the outer circle, inner hole, and thickness of the part.

[0029] 2. Analyze the relationship between the position of the hole on the circumference of the part and each datum.

[0030] Second, design and manufacture process equipment;

[0031] 1. Design of process equipment

[0032] a. Drill template design, the A datum radial dimension (a1) on the drill template (1) is determined by the A datum radial dimension (a) on the part, and the left end of the A datum on the drill template (1) has a chamfer , the angle between the chamfer and the A reference axis is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com