The application of zigzag arc extinguishing method of manual arc welding in the welding of q460 steel pipe

A technology of manual arc welding and bottom welding, applied in arc welding equipment, applications, welding equipment, etc., can solve problems such as difficult observation of molten pool, poor forming, excessive unevenness of weld bead, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

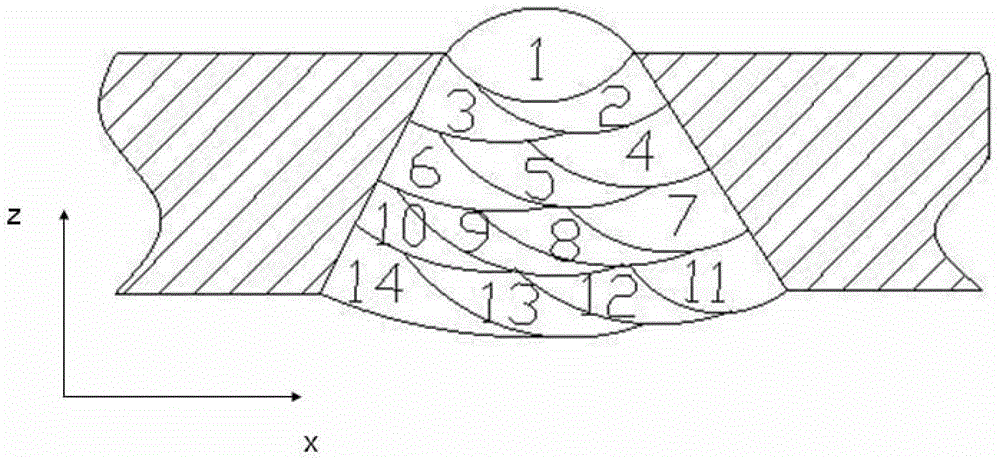

[0025] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0026] Choose two sections of φ400*16 steel pipes, the material is controlled rolling Q460 high-strength steel, and the groove and the surface are polished to a metallic luster within 10mm as required; the welding consumables are E6015-G, with diameters of 3.2mm and 4.0mm, as required Dry it at 350°C, keep it warm for 2 hours, then put it in the heat preservation cylinder, and turn on the power supply, and take it out whenever you need it.

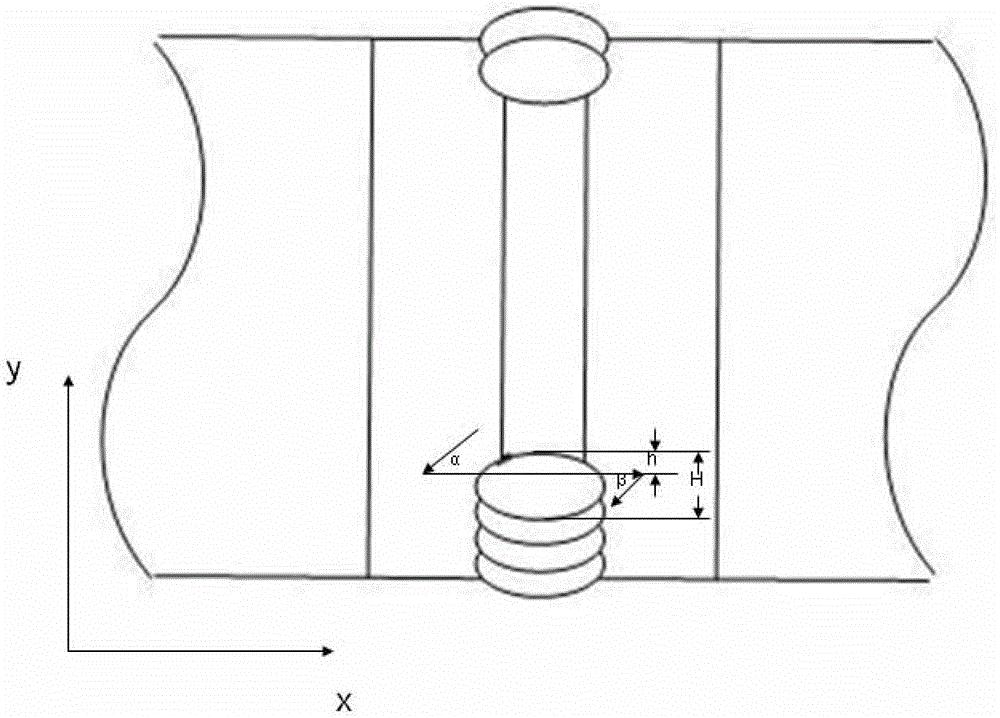

[0027] Matching parameters: groove angle 30-35°, root gap 3.5-4.5mm, blunt edge 1.0-1.5mm, misalignment less than 1mm. After the preparation is completed, tack welding is carried out at both ends of the test piece with a length of 15mm.

[0028] 1. Test materials and methods

[0029] The material used in the test is taken from ordinary Q460 angle steel with a thickness of 20 mm, and the welding material used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com