Method for operating a laser scanner and processing system with laser scanner

A technology of laser scanners and processing systems, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as prolonging processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the example embodiments described below, components with the same function and structure are marked with the same reference numerals as much as possible. Therefore, in order to understand the characteristics of individual components of a particular embodiment, reference should be made to the description of other embodiments of the invention and the summary.

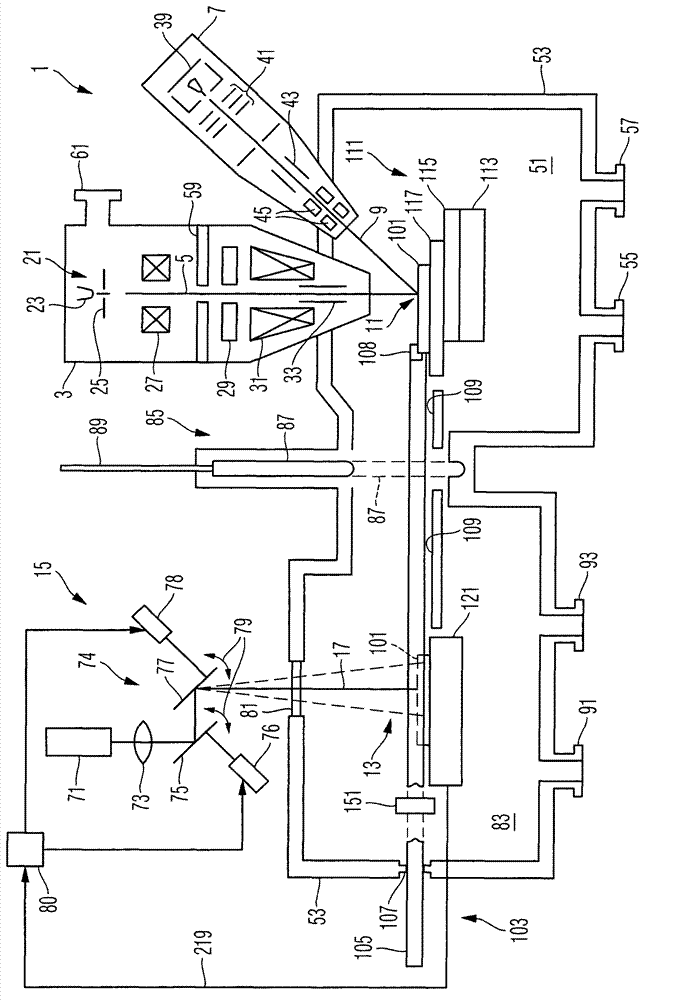

[0029] figure 1 is a schematic diagram of the processing system 1 . The machining system is configured to perform machining of an object using a laser beam and using a multi-particle beam. Background information on such a system can be found, for example, in US2011 / 0198326A1, the entire disclosure of which is incorporated in this patent application by reference.

[0030] The processing system 1 includes two particle beam columns, that is, an electron beam column 3 that generates an electron beam 5 , and an ion beam column 7 that generates an ion beam 9 . The ion beam 9 is directed to a processing area 11 like ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap