C-shaped frame squeeze riveting technology and anchor rivet nut thereof

A nut and riveting technology, applied in the field of riveting nuts, can solve the problems of easy slippage, thin nut wall, easy slippery teeth, etc., and achieve the effect of improving production efficiency, improving assembly strength, and not easy to slippery teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

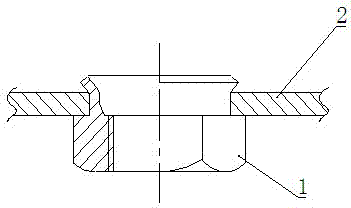

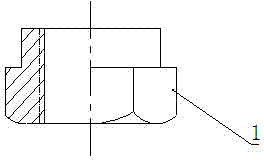

[0010] In the present invention, the C-shaped frame pressure riveting process is specifically: first punch the riveting hole at the riveted part of the C-shaped frame 2; figure 2 As shown, the inner hole of the rivet nut 1 is a long threaded hole, and the outer wall of the rivet nut 1 is a stepped shape with a large end and a small end.

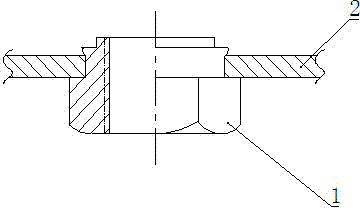

[0011] Put the small end of the rivet nut 1 into the hole of the C-shaped frame 2, and then put the two into the riveting die and perform riveting by a riveting machine; image 3 As shown, in this pressure riveting process, only the metal of the small end of the rivet nut 1 close to the outer wall is formed into a cover shape and closely attached to the riveting hole of the C-shaped frame 2, and the threaded hole at the small end of the rivet nut 1 is not deformed. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com