A Segmented CNC Self-Centering Steady Frame

A self-centering and steady rest technology, which is applied to large-scale fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of relying on the operator's operation and feeling, and the centering method is not very reliable, so as to improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

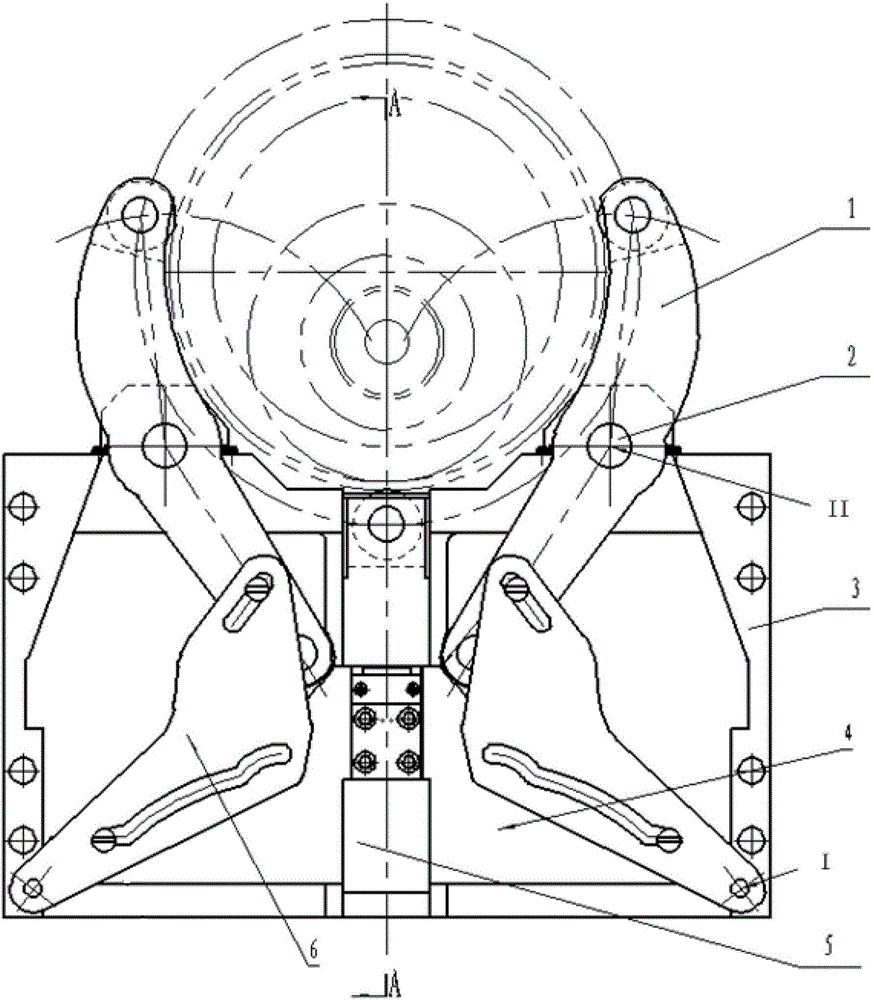

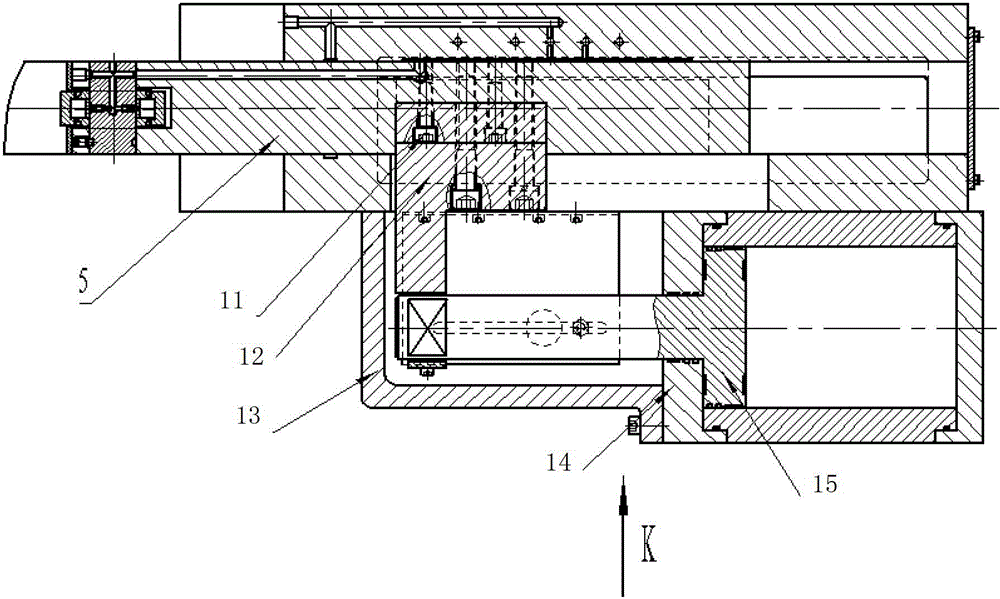

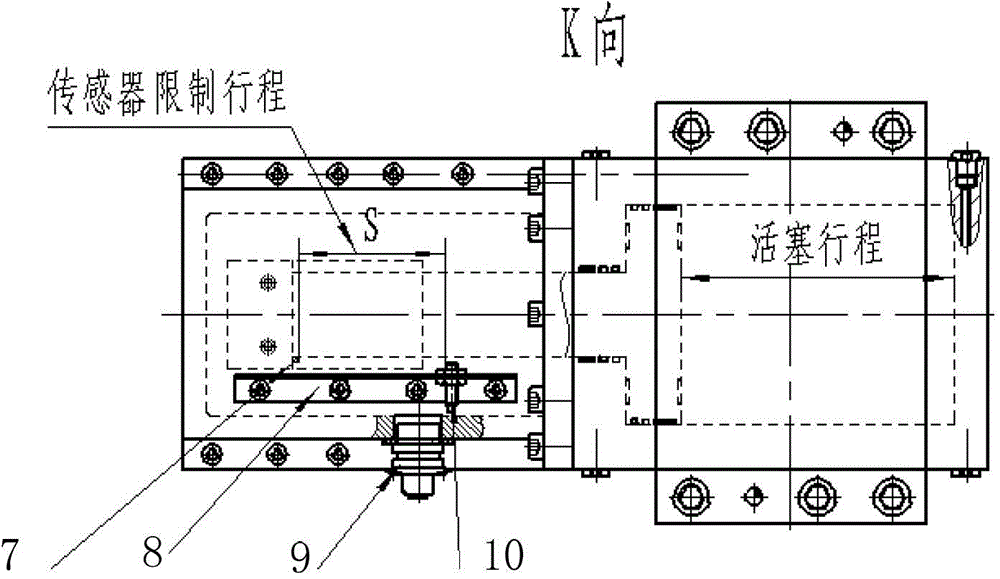

[0029] A segmented numerically controlled self-centering steady frame, comprising a body 3, two side arms 1, a drive cam 4, a cross arm 5, a body cover, two return mechanisms 6 and a push cylinder assembly, the body 3 is surrounded by The edge is provided with a raised outer edge, and two openings are respectively arranged at both ends on the outer edge of the top of the body 3, and the two side arms 1 are provided with round holes, and the inner side of the side arm 1 is an arc The drive cam 4 forms a plane protrusion from the center of the bottom to the top, and the top of the drive cam 4 transitions through a transition curve to the bottom. The top of the return mechanism 6 is provided with a driven groove 6-1, and the bottom is provided with a Active slot 6-2;

[0030] The opposite round holes of the two side arms 1 are respectively fixed in the opening on the outer edge of the top of the body 3 through two slewing bearings 2, and the bottom ends of the two side arms 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com