Adjustable rotation polishing machine

A polishing machine and adjustable technology, applied in the field of machine tools, can solve the problems of increased labor intensity, high processing cost, lack of positioning devices, etc., and achieve the effects of reducing labor intensity, good locking function, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

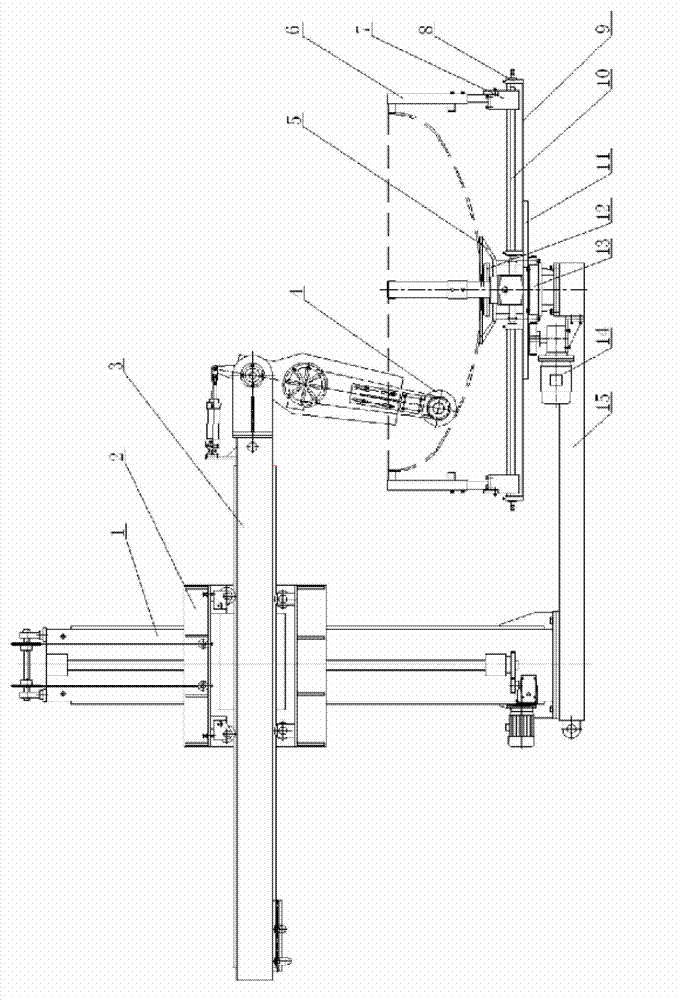

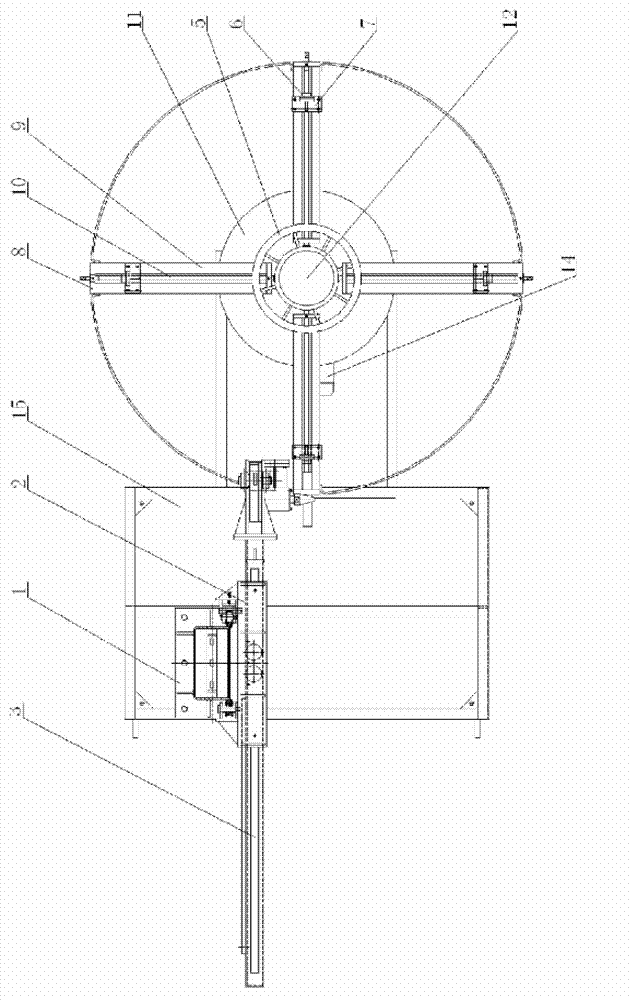

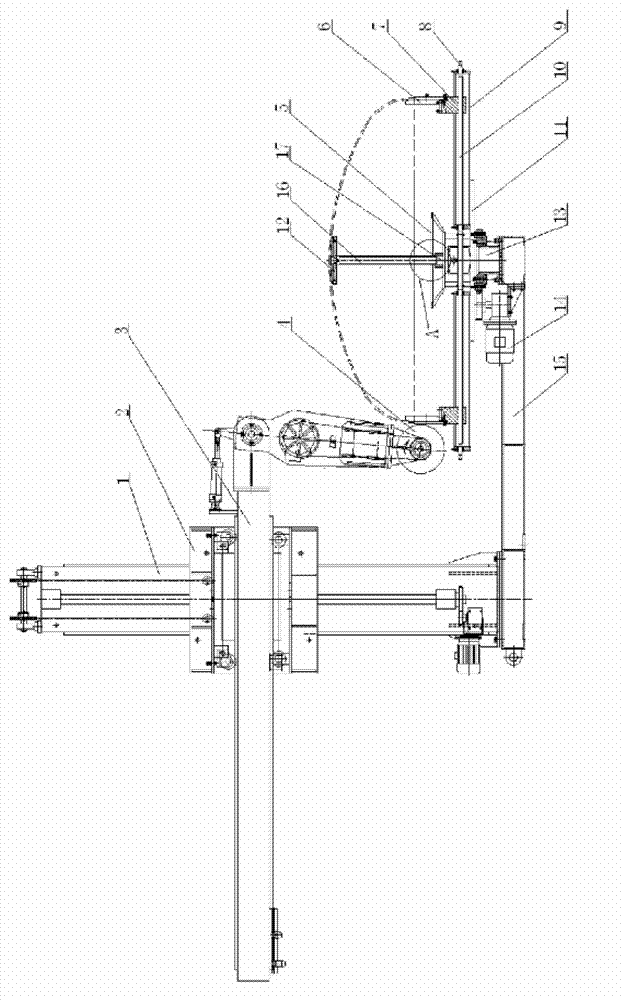

[0022] An adjustable rotary polishing machine, comprising a base 15, a lifting column 1, a horizontal guide rail 3, a polishing head 4 and a rotary worktable, a vertically fixed lifting column is mounted on the base, and a slider 2 runs vertically on the lifting column. A horizontal guide rail is horizontally slid on the slider, and the polishing head is hinged at the end of the guide rail. A rotary table is installed on the base corresponding to the bottom of the polishing head. The rotary table includes a rotary support seat 13 and a rotating disk 11. The seat is installed on the base, and the horizontal coaxial rotating disk is installed on the rotating support base. A motor 14 is installed on the base, and the motor drives the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com