Manufacturing method of composite hose

A manufacturing method and technology for composite hoses, applied in the field of hoses, can solve problems such as affecting bonding strength, difficult to manufacture, and easily damaged outer pipes, and achieve the effects of avoiding compression deformation and reliable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

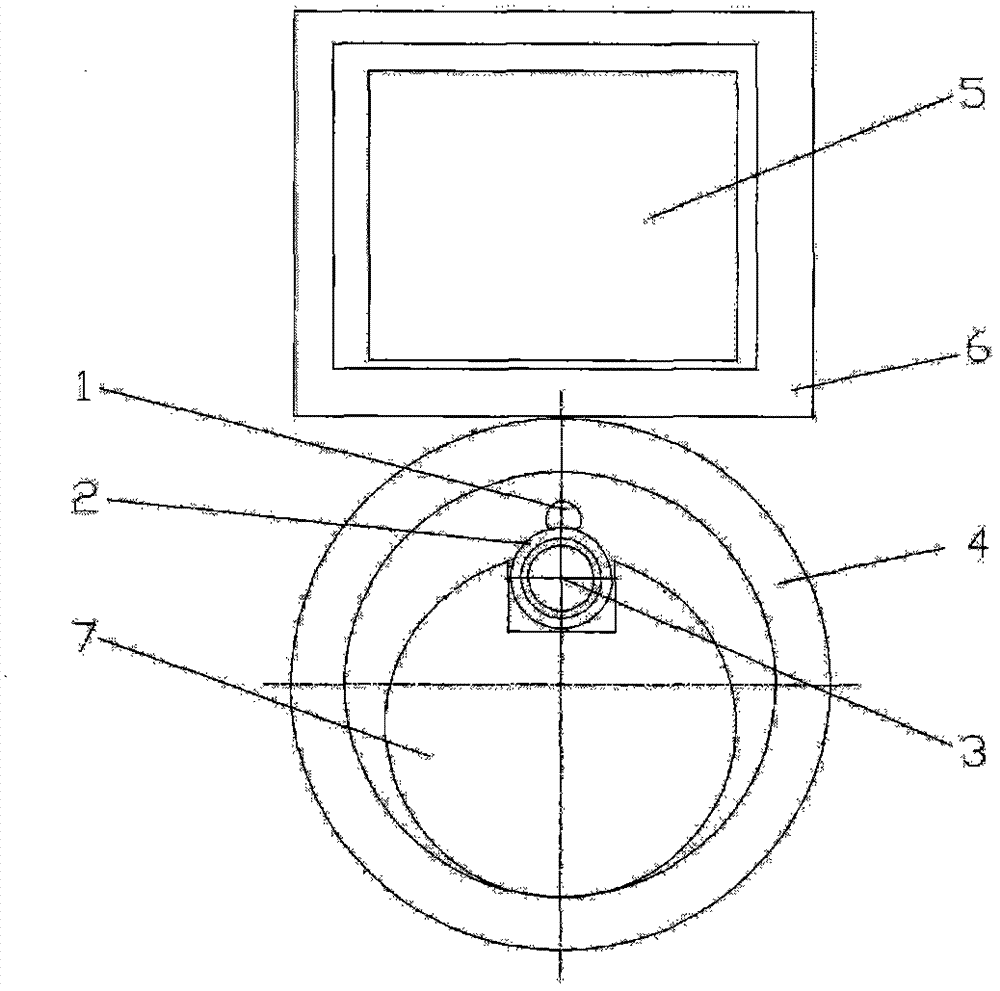

[0017] The composite hose manufacturing method of the present embodiment can be found in figure 1 ,Proceed as follows:

[0018] The first step is to use extrusion and injection molding machines to apply viscose 1 along the length direction on the outer surface of the small-diameter tube 2 to form a line, and insert it together with the iron rod 3 inserted in the small-diameter tube and the support rod 7 for placing the small-diameter tube in the gap Inside the large diameter tube.

[0019] In the second step, the electromagnetic frame 6 equipped with the electromagnet 5 is approached to the large-diameter tube 4 toward the side of the small-diameter tube 2 coated with the glue 1, and is attracted to each other with the iron rod 3, so that the small-diameter tube 2 is coated with the outer surface of the viscose 1 It is in close contact with the inner surface of the large-diameter pipe 4 .

[0020] In the third step, after the inner surface of the small-diameter tube 2 and th...

Embodiment 2

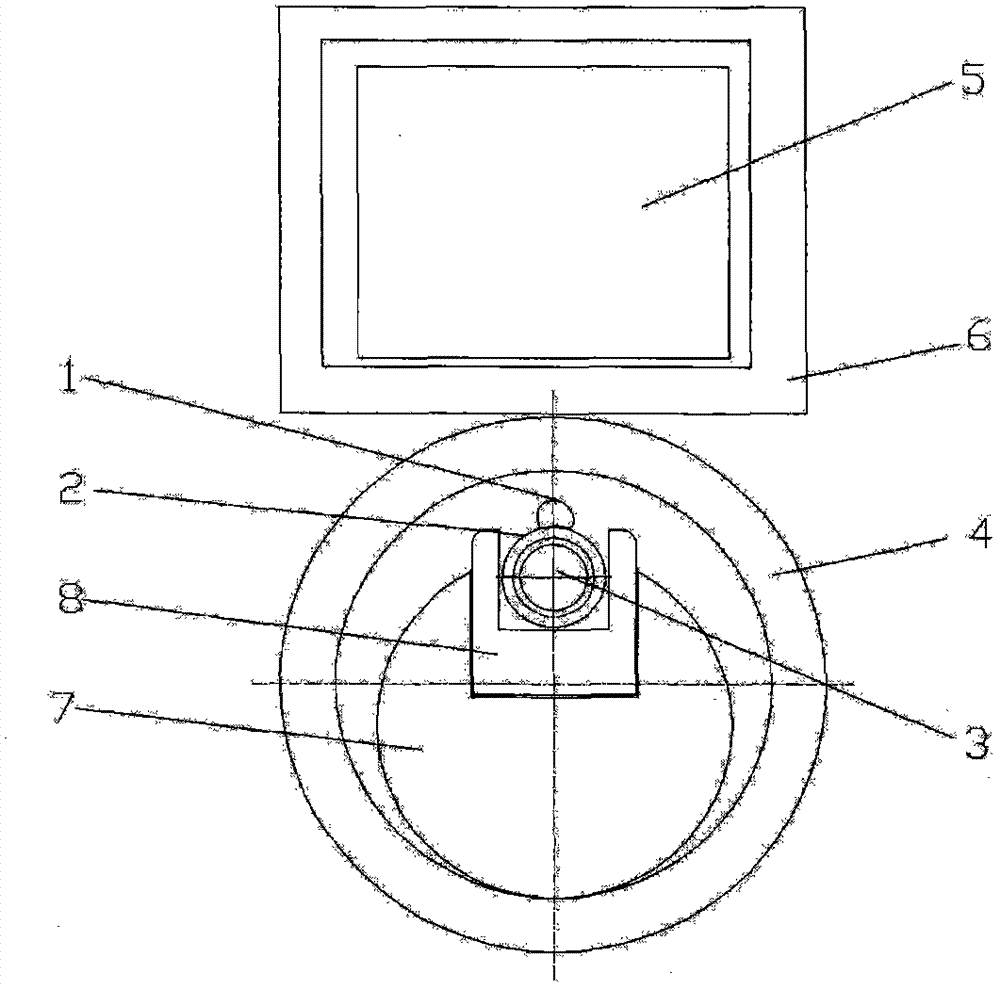

[0023] The composite hose manufacturing method of the present embodiment can be found in figure 2 , the basic steps are the same as in Embodiment 1, the glue is hot melt glue, the main difference is that the small-diameter tube 2 inserted with the iron rod 3 is embedded in the groove of the magnetic groove 8 and is located in the gap of the support rod 7, and the small-diameter tube The diameter of 2 matches the width and depth of the groove. When the external electromagnetic frame approaches the large-diameter tube 4 toward the hot-melt adhesive on the small-diameter tube 2, it will attract each other with the iron rod 3 and the magnetic groove 8, so that the outer surface of the small-diameter tube 2 coated with the hot-melt adhesive 1 and the large-diameter tube The inner surfaces of 4 are in close contact. After the hot melt adhesive makes the small-diameter tube 2 adhere to the inner surface of the large-diameter tube 4, remove the electromagnetic frame, and pull out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com