Auxiliary braking device of cordless elevator and control method thereof

A technology of auxiliary braking and electronic control unit, which is applied in the direction of transportation, packaging, elevators, etc., can solve the problems of elevator danger, increase of elevators, increase of cost of effective area of buildings, etc., and achieve high-speed braking performance and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

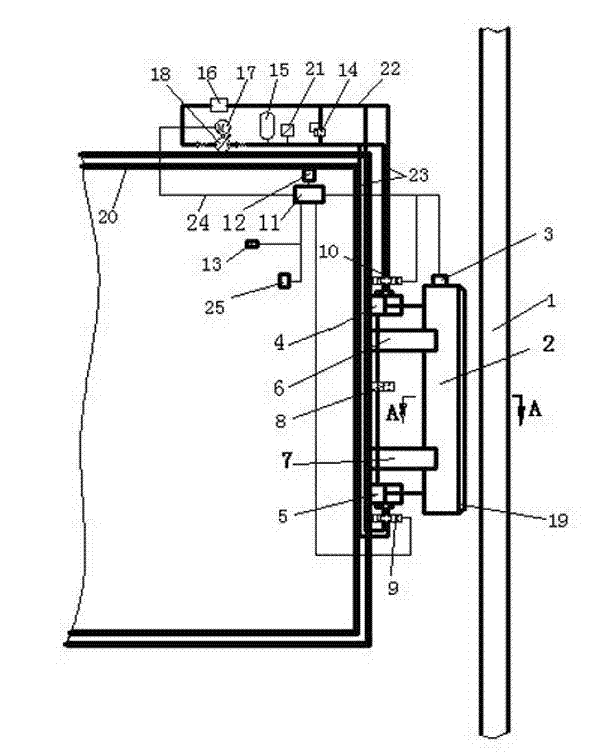

[0018] Such as figure 1 , the present invention includes a linear permanent magnet brake, a hydraulic energy supply system, an electronic control system and a rail 1.

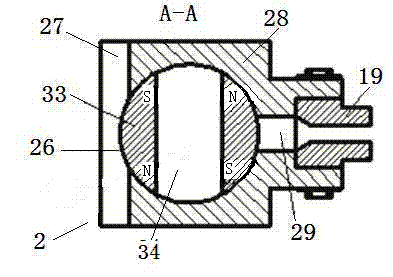

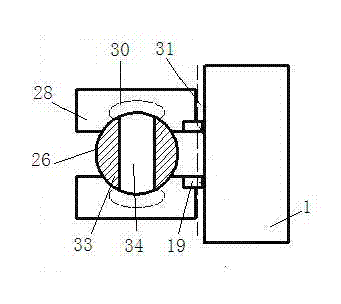

[0019] Wherein the linear permanent magnet brake comprises a brake body 2, a brake shoe 19, force transmission guide pillars 6 and 7, and a rotating mechanism 3. The rail 1 is vertically fixed on the shaft, and there are brake body 2 and brake shoes 19 between the rail 1 and the bridge compartment 20. The brake shoes 19 are fixedly installed on the brake body 2, and the brake shoes 19 face the rail 1 and are parallel to the rail 1. layout. The bridge compartment 20 and the gate body 2 are connected by two force transmission guide columns 6 and 7, the two force transmission guide columns 6 and 7 are arranged in parallel up and down, and one end of the two force transmission guide columns 6 and 7 is fixedly connected to the bridge compartment 20 The side is fixed and the other end is slidingly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com