Soft polyurethane foam material for bulk solid consolidation

A soft polyurethane and foam material technology, applied in the field of polyurethane materials, can solve the problems of large compressive residual strain, low compression set, low tensile strength and bonding strength, etc., and achieve excellent durability and excellent physical and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

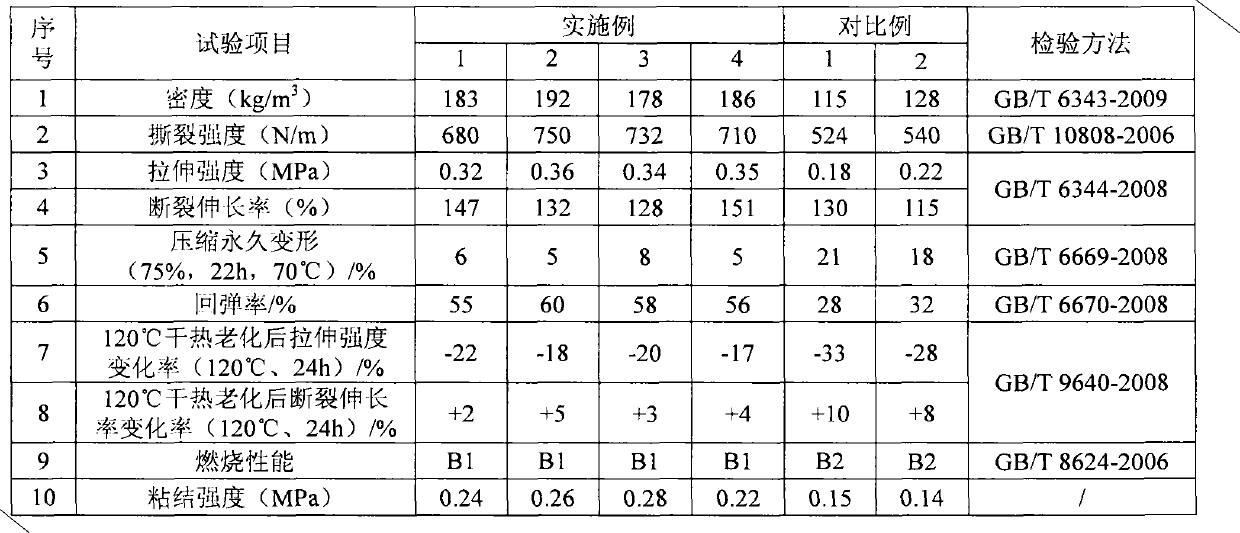

Examples

Embodiment Construction

[0023] The implementation and beneficial effects of the present invention are described below through specific examples, but the present invention is not limited thereto.

[0024] Adjust the temperature of all raw material mixtures (polyol system) and isocyanate to (25±1)°C, respectively, except for isocyanate. Measure the amount of each raw material according to the mixing ratio described in Table 1, then add the isocyanate into the polyol system, and stir and mix with a high-speed mixer at a speed of 3000 rpm for 10 seconds. The newly mixed polyurethane slurry is injected at room temperature into a cylindrical mold with a diameter of 500mm and a height of 500mm that is open at the top and covered with a polyethylene film. After 15 minutes, take out the soft polyurethane foam from the mold, cool it to room temperature (23±2)°C, and then place it in a constant temperature and humidity curing box with a relative humidity of 50% and a temperature of (23±1)°C for 48 hours before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap