Tightness-adjustable composite material coupling member and fabrication method and assembly of coupling member

A technology of composite materials and connecting components, applied in the processing and application fields of connecting components, can solve the problems of great differences in rigidity and corrosion resistance, hidden dangers of transmission line safety, single structure of connecting components, etc., to achieve strong corrosion resistance and reduce investment. , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

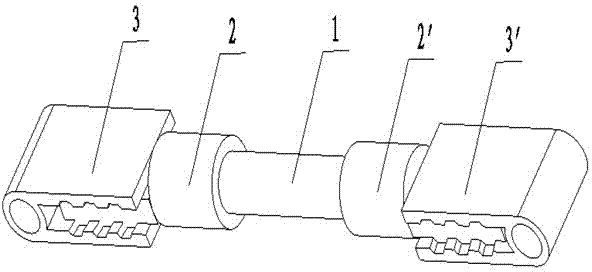

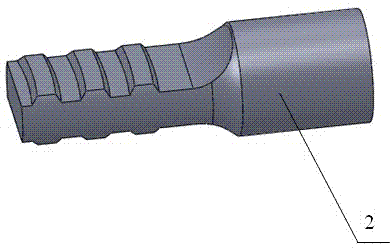

[0027] Such as Figure 1-Figure 5 As shown, in the present invention, the adjustable elastic composite material connecting member is composed of a cylindrical connecting rod 1 that is prefabricated at one end with positive buckle male thread and with the other end prefabricated with reverse buckle male thread; The connection plates 2, 2'; and the U-shaped connection plates 3, 3' respectively connected to the free ends of the connection plates 2, 2' are assembled.

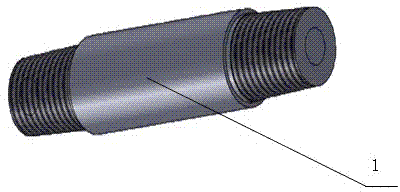

[0028] Wherein, the connecting rod 1 is a cylinder with a diameter of 40-100 mm and a length determined by the distance between the insulating rods connected to the connecting member, usually 150-1500 mm; one end of the cylindrical connecting rod 1 is prefabricated The positive buckle male thread and the other end prefabricated reverse buckle male thread; the length of the positive buckle male thread is the same as the length of the reverse buckle male thread, both 60-75mm; the tooth height of the thread is 2-3mm, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com