Disc spring type vibration attenuation thrust bearing

A thrust bearing and thrust shaft technology, applied in the field of thrust bearings, can solve problems such as high longitudinal natural frequency of the shaft system, high longitudinal stiffness of the thrust bearing, increase vibration transmission, etc., and achieve increased natural frequency ratio of the shaft system and uniform internal load , the effect of increasing the excitation frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, patent of the present invention is described further.

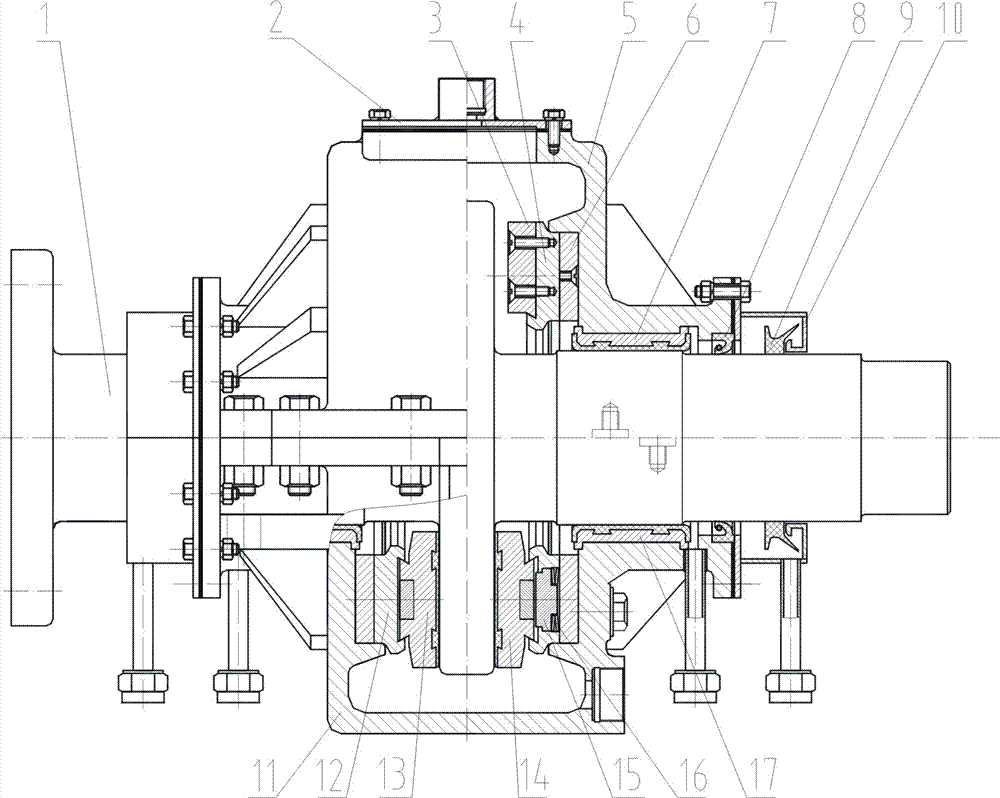

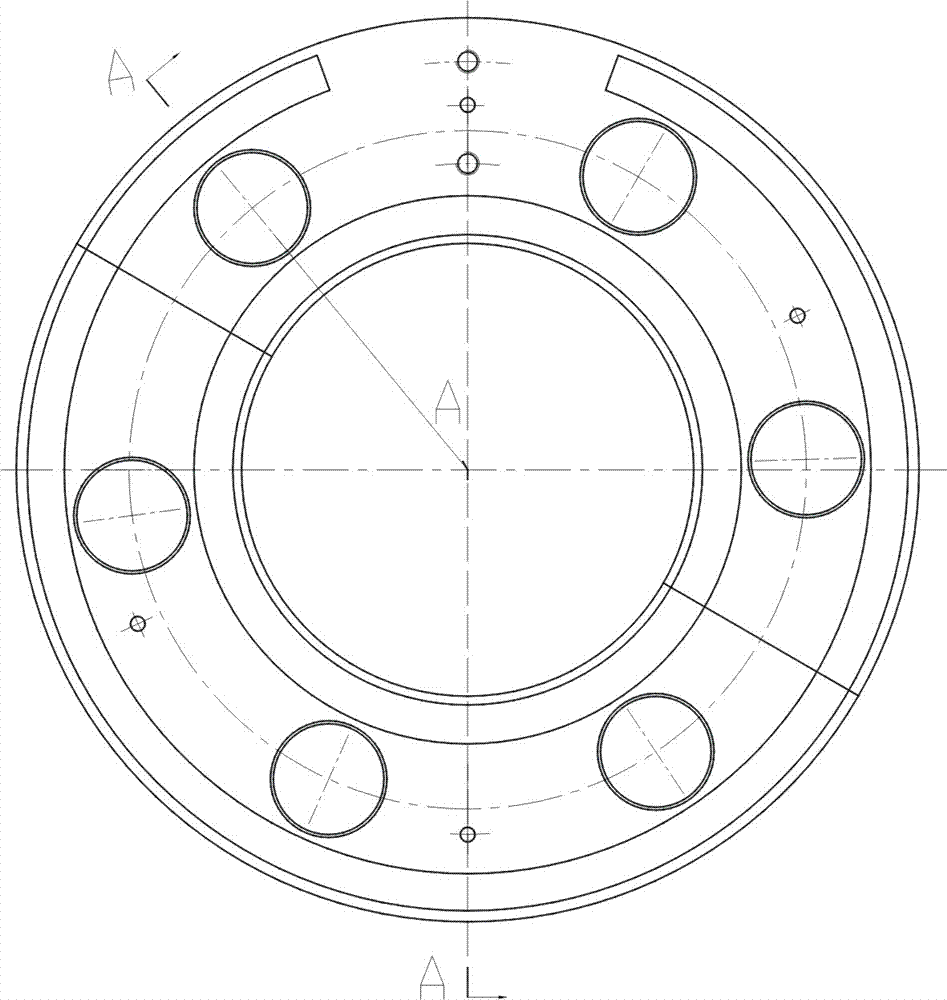

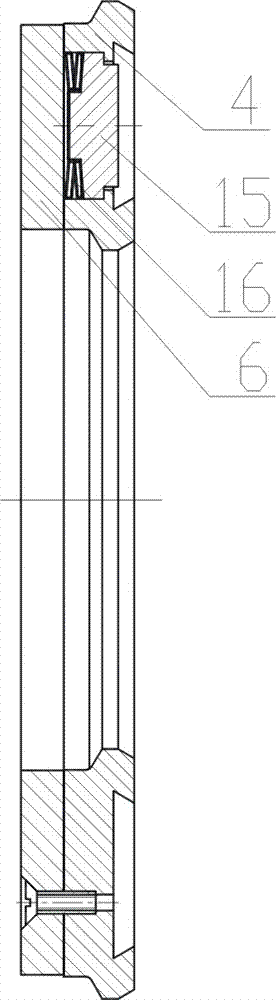

[0021] Such as figure 1 As shown, the disc spring damping thrust bearing includes an upper casing 5, a lower casing 11 and a thrust shaft 1. Both the upper casing 5 and the lower casing 11 are cast, which are the bases for arranging the main parts of the bearing. There are bearing bush holes on both sides of the shell assembled by the upper and lower shells. The thrust shaft 1 is supported in the bearing bush holes of the shell. The left and right ends of the thrust shaft 1 are respectively supported on the radial bearing bushes. The bearing pad is composed of an upper bearing pad 7 and a lower bearing pad 17 whose inner surface is a semi-cylindrical surface, and is fixed on the upper casing 5 and the lower casing 11 by screws. Both ends of the housing are flanged to the end cover 10, and an oil deflector ring 9 and an oil seal 8 are sequentially arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com