a v-shaped pulley

A pulley and wheel technology, applied in the direction of belt/chain/gear, elements with teeth, hoisting device, etc., can solve the problem of increasing transmission force and torque, high manufacturing cost of pulley, low manufacturing cost of pulley, etc. problems, to achieve the effect of increasing the transmission force and torque, not easy to wear, not easy to slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

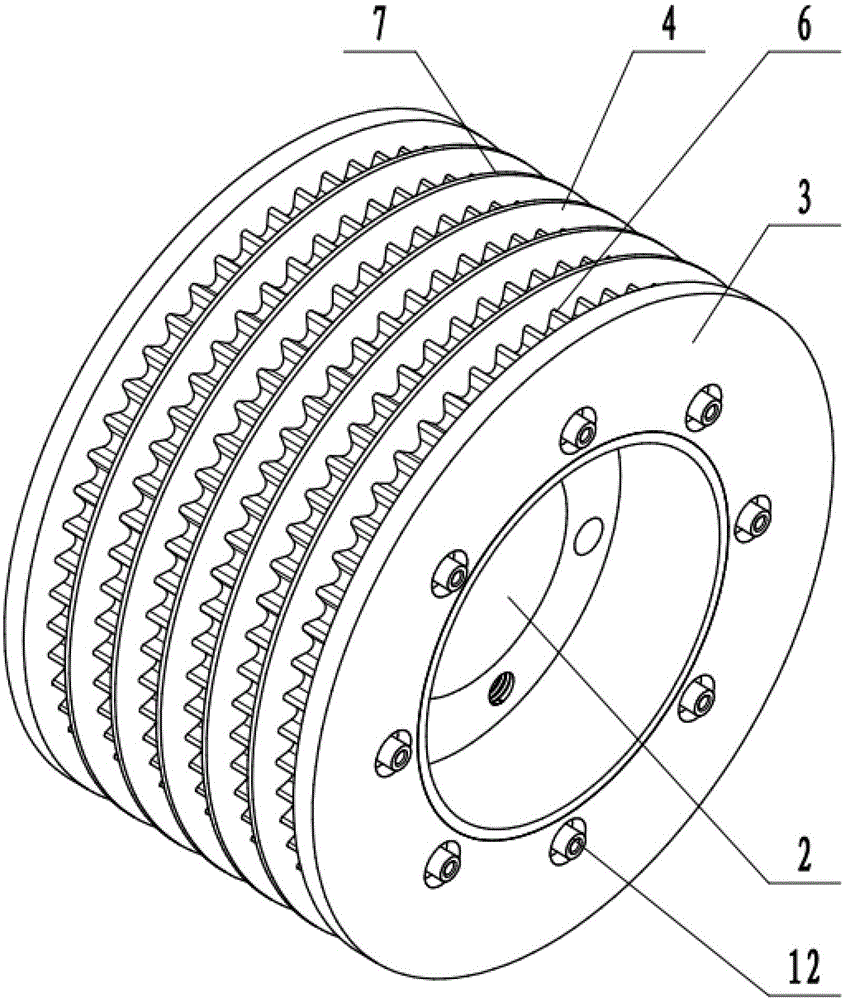

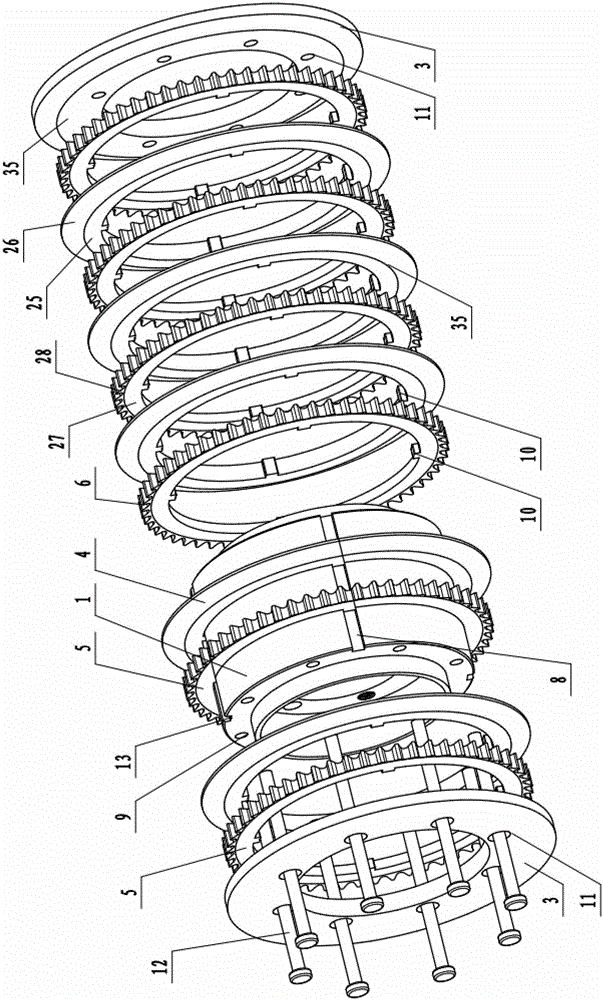

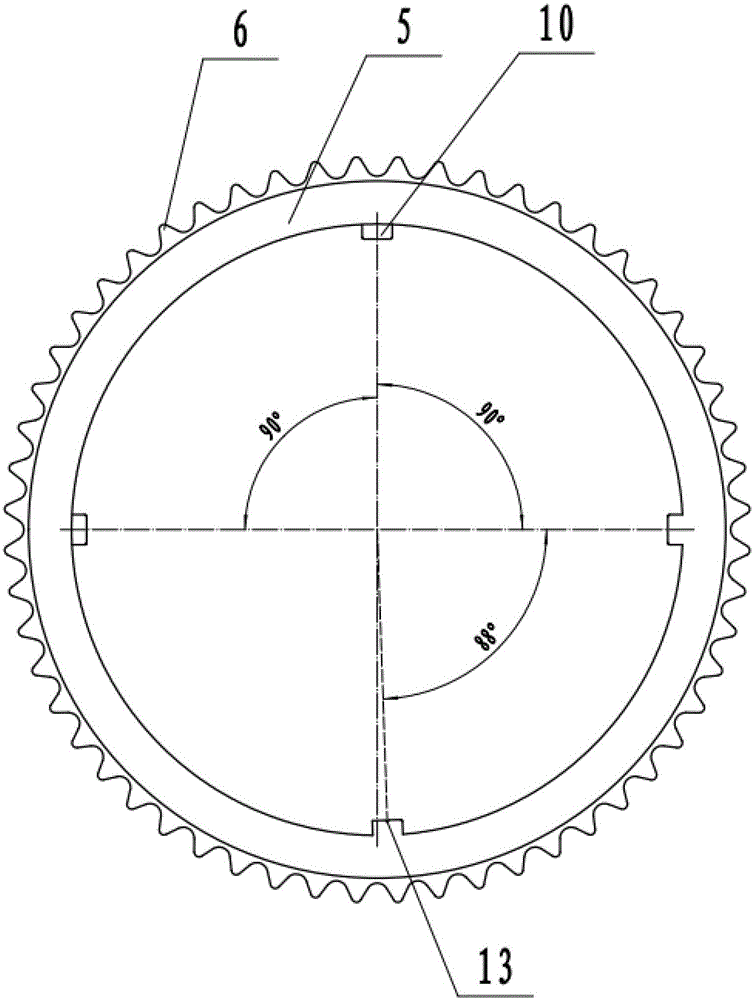

[0031] Embodiment 1: a kind of V-type belt pulley (referring to attached figure 1 , attached figure 2 ), including a cylindrical pulley body 1, a through hole 2 is provided in the center of the pulley body, and a positioning ring 29 is provided at both ends of the pulley body (see attached Figure 5 ), the positioning ring is close to the edge of the through hole and coaxial with the through hole, the inner diameter of the positioning ring is the same as the aperture of the through hole, and the inner wall of the through hole of the main body of the pulley is provided with an inwardly protruding annular protruding ring 30, and the two ends of the protruding ring They are arranged inside the two ends of the main body of the pulley respectively, and the protruding rings are integrated with the main body of the pulley, and the end faces of the protruding rings are provided with six axial conduction holes 31 . The main body of the pulley is connected with a wheel, and the wheel ...

Embodiment 2

[0035] Embodiment 2: a kind of V-shaped belt pulley (referring to attached Figure 6 ), consisting of a cylindrical pulley body 1 (see attached Figure 10 , attached Figure 11 ), the center of the main body of the pulley is provided with a through hole 2. The main body of the pulley includes a coaxial inner ring body 32 and an outer ring body 33. The inner ring body and the outer ring body are connected by six connecting ribs 34 evenly distributed. On the inner side of the two ends, the inner ring body, the connecting rib and the outer ring body are connected together to form an integrated structure. The inner hole of the inner annular body is used as the through hole of the main body of the pulley. The main body of the pulley is connected with a wheel piece, and the wheel piece includes an outer wheel piece 3 and an inner wheel piece 4. An outer wheel piece is respectively provided at both ends of the pulley body, and one of the two outer wheel pieces is the first outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com